3372

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Figure 1. Typical pile heat exchanger at the site (after breaking down to

pile cut off level).

2.1 Ground Conditions

The site is underlain by a sequence of London Basin deposits.

The piles are founded in the London Clay at 21m depth, but also

pass through a significant thickness of superficial and man-

made deposits (Table 1). As the site is located close to the

confluence of the Thames and the River Lea in east London, the

groundwater table is close to the ground surface, near to the

base of the Made Ground.

Table 1. Table Ground Conditions.

Strata

Description

Depth (m)

Made Ground

Fine to coarse brick and

concrete gravel; soft to firm black

sandy gravelly clay.

3.3

Alluvium

Very soft clayey silt, sandy

clay and peat.

6.3

River Terrace

Deposits

Medium dense silty fine to

coarse sand and fine to coarse

gravel (mainly flint)

11.2

London Clay

Stiff thinly laminated fissured

silty clay with silt partings

23.5

2.2 Instrumentation

One 1200mm diameter pile near the north east corner of the

building was selected for monitoring. The pile was equipped

with five thermistor strings. One of these was attached to the

central bundle of plastic pipes, themselves inserted into the pile

attached to a 40mm steel bar for stiffness (Figure 2). The U-

pipes, the steel bar and the thermistor strings were installed to a

depth of 20m within the pile. The other four thermistor strings

were attached at equal spacings around the circumference of the

steel reinforcing cage (Table 2). As the pile cage only extends

to 8.5m below the pile cut off level it was not possible to extend

the outer thermistor strings over the full 21m pile depth.

3 BACKGROUND DATA

Following construction of the pile, selected thermistors were

monitored for approximately one month to provide an indication

of the heat of hydration. During this period the groundworks

beneath the building footprint were completed and all the pipe

circuits were constructed as far as the header chambers. At this

point it became possible to data log all the monitoring points to

obtain information on the background soil temperatures at

different depths.

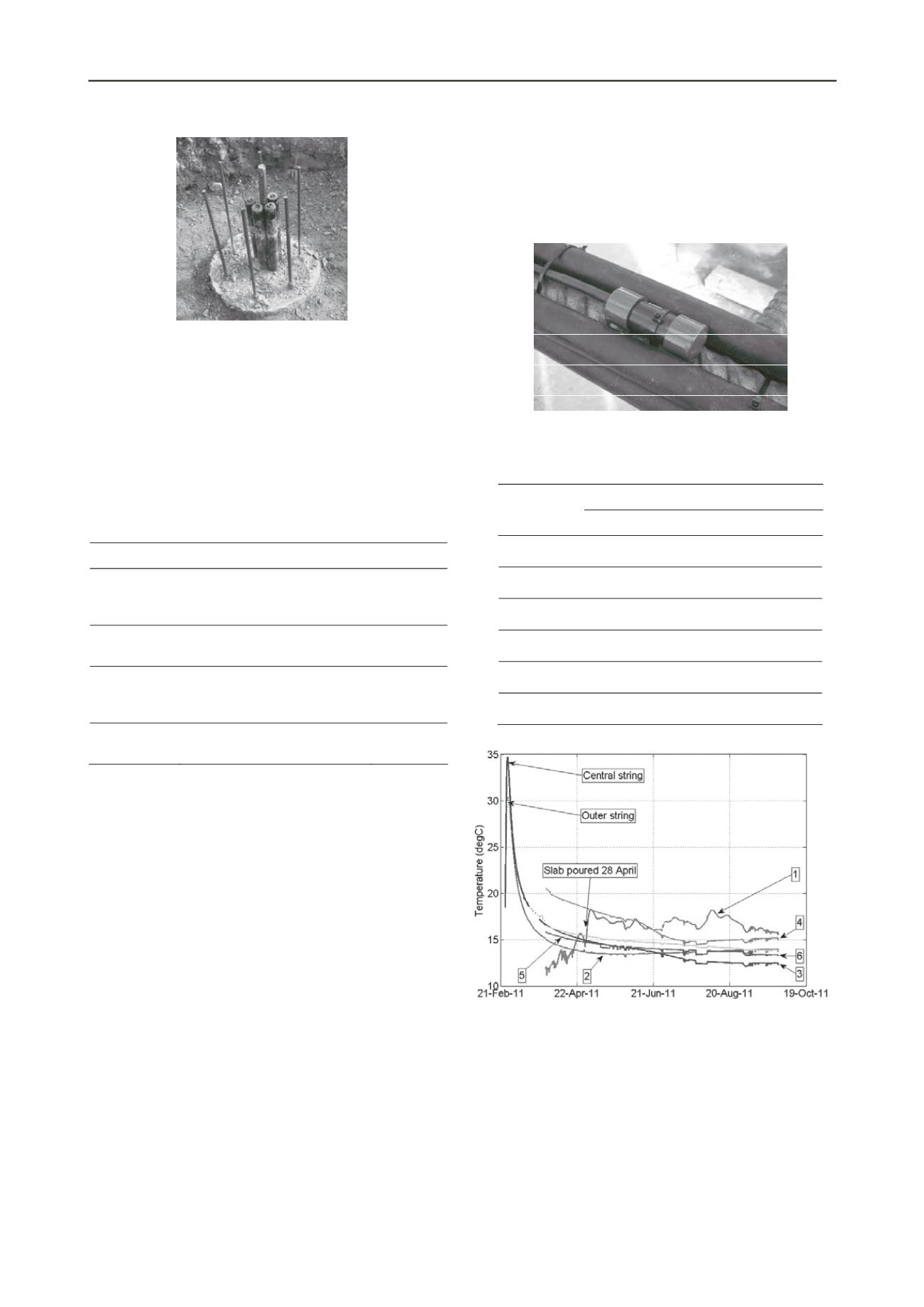

These initial data are presented in Figure 3. It can be seen

that during curing the pile reaches temperatures of almost 35

o

C

at its centre, but that this reduces to approximately 30

o

C closer

to the pile edge. In the main part of the pile, it takes over two

months for the heat of hydration to dissipate fully and

temperatures to return to between 13

o

C and 15

o

C. The near

surface monitoring points (thermistor level 1, Figure 3) are

influenced by the ambient air conditions. Within one month

(when monitoring of these points first commenced) the

thermistors at level 1 are already showing daily and longer term

seasonal fluctuations reflecting the local air temperature.

Figure 2. Base of the central thermistor string prior to installation of the

U-tubes and steel bar.

Table 2. Depths of thermistors installed with the pile.

Depth Below Pile Cut Off Level (m)

Thermistor

Level

Central String

Outer Strings

1

0.7

0.75

2

3.6

3.25

3

7.1

6.6

4

11.1

-

5

15.1

-

6

19.1

-

Figure 3. Initial pile temperatures during and after concrete curing

(numbers refer to thermistor string levels).

The level 1 thermistors also show a distinct increase in

temperature at the end of April 2011, coincident with the date at

which the floor slab for the building was cast. This temperature

increase will represent the additional heat of hydration from the

concrete slab. Following this time, daily variations of

temperature are also reduced due to the additional insulation. It

is also interesting to note these level 1 temperatures appear to

remain elevated for some time after the slab is cast; although it

is difficult to separate this effect from that of the surface air

temperature which would also be increasing at this time of year.