3364

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

and coarse grained soils: coarse grained soils presents some

structure alterations after freeze thaw cycles, fine grained soils

presents heaves and changes of plasticity index due to water

pulling during freezing. Most damages in road structures occur

when subsoil on ground surface is made of fine grained soils

(ZTVE-StB 94).

Forages of vertical borehole heat exchangers attain depths in

order of 100 m. Therefore, increasing of effective pressure with

depth reduces the negative effects of freeze, as described by

Ruckli (1950): for example, frost heave velocity for soils with a

grain size between 0.005 mm and 0.010 mm decreases as

pressure increases and is around equal to zero for pressures

higher than 30 kN/m². Consequently, stress distribution in the

soil and therefore on the borehole heat exchanger is considered

as an important influence parameter. It leads to suppose that soil

has a positive effect on frost resistance of the whole system,

what should be verified here experimentally.

3 ACTUAL STANDARDS AND TESTS

There is actually no guideline for evaluating the frost resistance

of vertical borehole heat exchangers. Developing a new

procedure consists in defining the test experiments and the

criteria regarding freezing resistance of the material. Following,

an overview of the existing tests on freeze thaw resistance of

different types of materials is given as base for possible

procedures; under consideration that it should be further

investigate with boundary conditions from vertical borehole

heat exchangers.

German and international standards for freeze-thaw

experiments on soils exist for natural stones and aggregates. The

German standard DIN 52104:1982 which gives instructions

regarding freeze-thaw behavior of natural stones was replaced

by the standard DIN EN 12371, from which the latest edition

appeared in 2010. Details about the determination of the freeze

thaw resistance of aggregates are given in the German standard

DIN EN 1367-1.

For unconsolidated material such as clay, silt and sand, there

are no rules and standards. However, those types of soil are

subject of research investigations (Rückli 1950, Simonsen and

Isacsson 2001, Andersland and Ladanyi 2004).

For freeze thaw resistance of hardened concrete according to

the common standards, a distinction between freeze-thaw-

resistance on the one hand with and on the other hand without

de-icing agents is made (pre-standard DIN CEN/TS 12390-

9:2006). The first one corresponds to the resistance to repeated

freeze-thaw cycles in contact with water. In case of the second

one, the specimen is in contact with road salt. Usually the de-

icing agent corresponds to a 3% NaCl solution. In the pre-

standard DIN CEN/TS 12390-9 three methods are described:

the slab test as a reference, the cube method and the CF and

CDF testing (Capillary Suction) as alternatives. The difference

between CF and CDF method is the test fluid (with water or

with deicing agent).

Although no standards are available about freeze thaw

resistance in application to borehole heat exchanger, some

research reports deals specifically with freeze effects on grout

materials (Herrmann 2008, Müller 2009, Niederbrucker et al.

2008).

Following test procedure takes care of those different

standards and research reports and extends the actual analyses

considering effects of freeze thaw with the surrounding soil.

4 EXPERIMENTS AND RESULTS

4.1

Preliminary tests

Experiments are conducted in a cylindrical encasement with a

sample of grout material and soil. A more detailed description

of the system for those tests is available in the next part.

Preliminary tests has been conducted on samples with reduced

dimensions in order to investigate the influence of water

saturation of the surrounding soil and to validate the assembly

procedure.

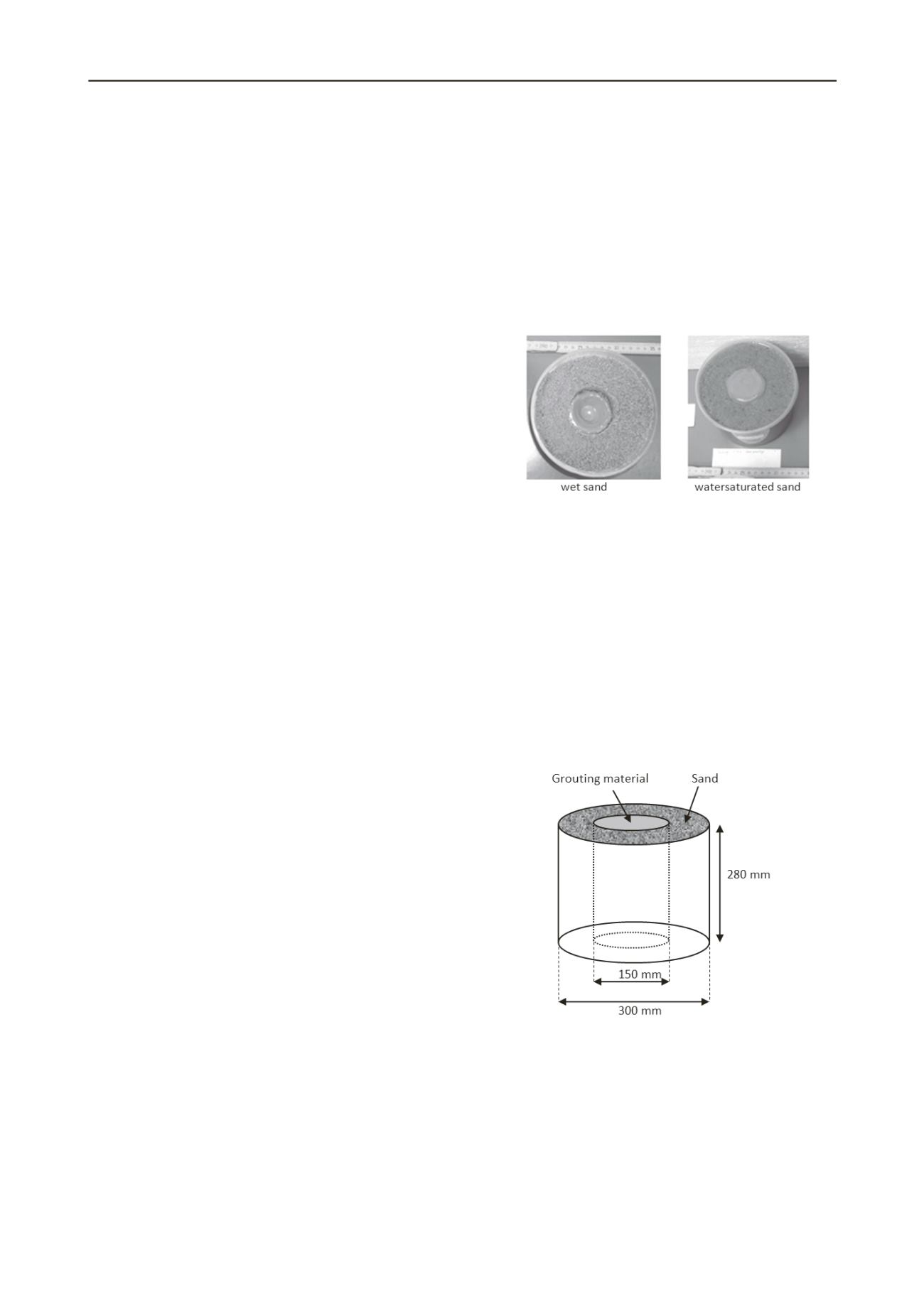

Two samples of cement and sand are represented on figure 1.

In both cases, cement characteristics and assembly procedure

remains the same. If the surrounding soil has a low saturation

degree, a cone appears on the upper part of the cement cylinder.

The cement part possesses in this case higher unconfined

compressive strength and modulus of elasticity with an

increasing rate in the order of 40 %.

Figure 1: Influence of the water saturation of the surrounding soil

4.2

Test procedure

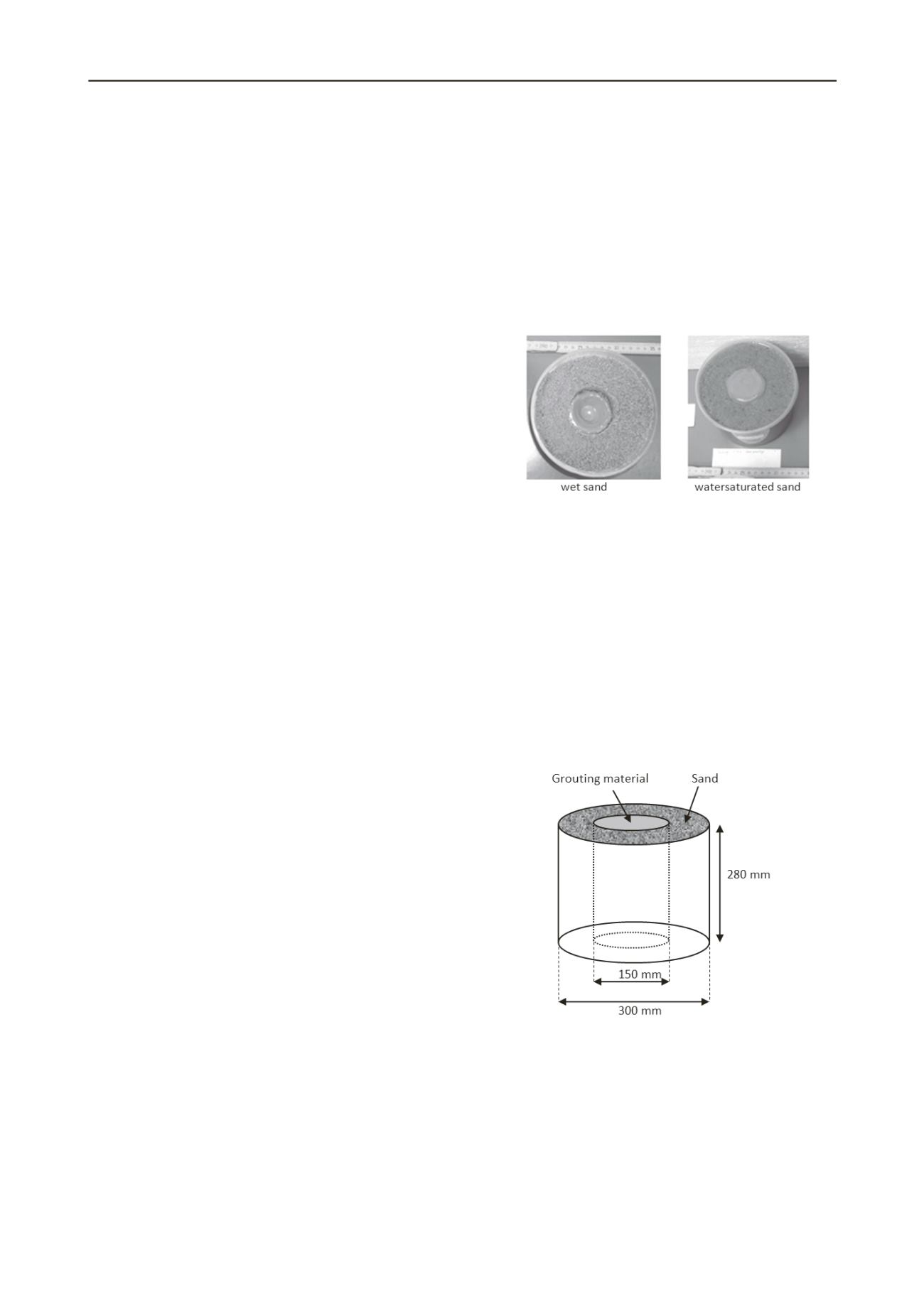

In order to avoid scaling factors, diameter of the grouting

material cylinder is in the same range of diameters of real

borehole heat exchangers, see figure 2 and 3. Dimensions of the

cylindrical encasement were then selected taking in

consideration the following statements: on one side, a large

distance between rands of grouting material and rands of

encasement limits the effects of deformations of the encasement

on the grout material due to high temperature changes; on the

other side, an increasing quantity of soil may lead to longer

procedure time due to freezing and thawing periods and to more

constraints regarding transport and storage due to an higher

weight of the sample, which are to be considered for a

reproductible procedure.

Figure 2: Dimensions of the samples of soil and grouting material