3360

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

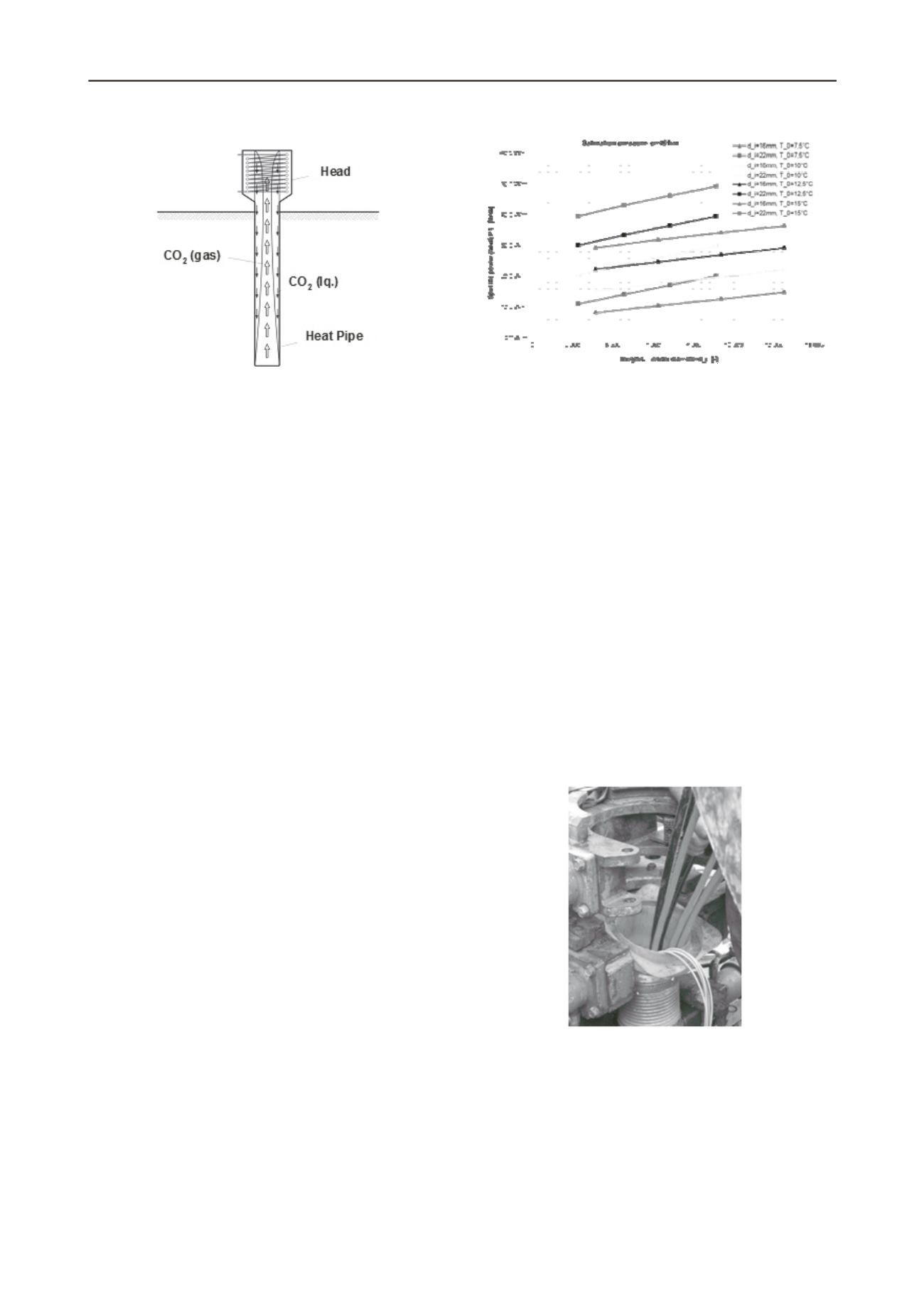

Figure 2: Heat Pipe: Geothermal Heat Pipe: Configuration

Furthermore, the temperature distribution within the

borehole heat-exchanger is advancing a high energy withdrawal

rate much more than conventional systems: The overall energy

withdrawal rate is predominantly governed by the temperature

difference between borehole heat-exchanger and ambient

ground temperature, which by itself is limited in terms of its

lower margin. Hence, a heat pipe borehole heat-exchanger is

exploiting the usable temperature more efficient than

conventional borehole heat-exchanger systems.

2 SIMULATION OF GEOTHERMAL HEAT PIPE

OPERATION

The thermal performance of a heat pipe is dependent on a

number of influencing parameters, e.g. driving temperature

difference, mechanical and thermal properties of the heat carrier

fluid – in the present case CO

2

– such as evaporation enthalpy,

heat conductivity and capacity, viscosity, the energy withdrawal

rate on the condenser side, the geometric dimensions and

particularly the inside pressure and the amount of filling

medium respectively, compare to Dunn and Reay (1993) and

Lee and Mital (2003).

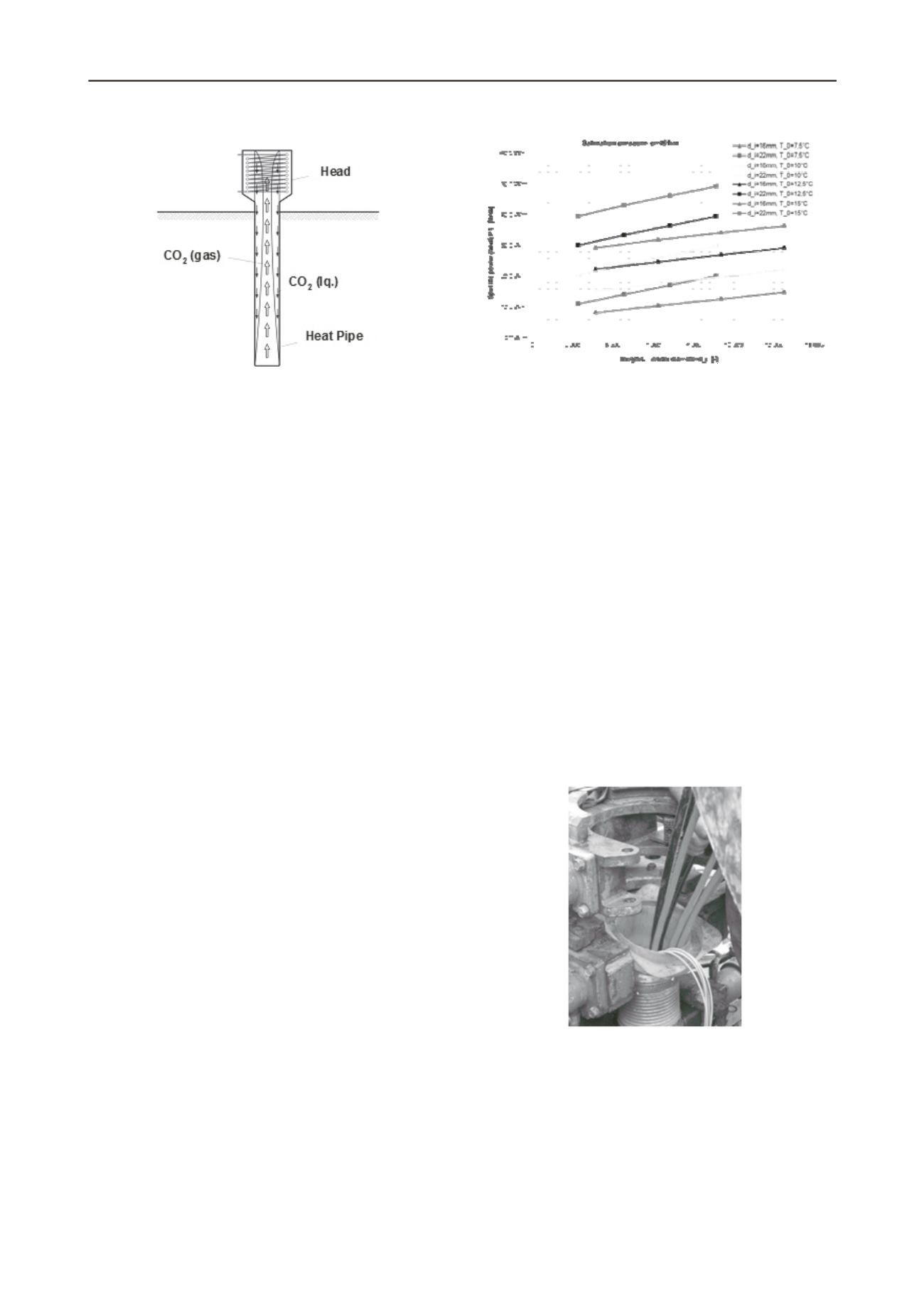

Based on a numerical algorithm and accounting for the

conduction-governed energy transport from the soil to the

cylinder and the convection-governed energy mechanism within

the cylinder in vertical direction and considering both surface

evaporation and boiling evaporation, an extensive number of

computations were conducted in order to investigate the

sensitivity to various parameters such as overall length,

diameters of heat pipes and boreholes. The resulting specific

power for a given set of parameters for a constant saturation

pressure is plotted in Figure 3.

The exceptionally efficient energy transport within the heat

pipe and the obsolete circulation pump in comparison to

conventional borehole heat exchangers allow a relative increase

of the coefficient of performance (COP) of up to more than

10°% (percentage).

Figure 3: Simulated heat pipe performance: Energy withdrawal

rate(specific power: heat)

During the operation of such a Two-Phase-Heat Pipe the

thermal transfer resistance in film evaporation or condensation

is significantly smaller in comparison to a system without phase

change. Accordingly, a significantly smaller driving

temperature difference between soil temperature and heat pump

evaporator is necessary to archive the same overall heat flux

density.

The relation between length and diameter has large

influence on the specific power (heat). Accordingly, it is

desirable to optimize this geometric relation during

dimensioning and design.

3 CASE STUDY OF APPLICATION

Within a pilot project, a new-construction one-family home has

been equipped with a ground-coupled heat pump in

combinations with geothermal heat pipe borehole heat

exchangers. These have been instrumented for long term

measurements of ground temperatures and heat pump

parameters(see Figure 4).

Figure 4: Measurement installation

The obtained temperature records (Figure 5) can be used to

investigate the overall performance of the energy supply system

as well as to analyse the operation and to control the

functionality of the installation.