3353

Technical Committee 307 + 212 /

Comité technique 307 + 212

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

excavated pit. The excavated soil must be well suited and

compactable for this purpose.

3 CONSTRUCTION AND SITE INVESTIGATIONS

In Marstal the PTES is placed on the top of a smooth hill in the

outskirts of the town.

Due to area restraints the pit is slightly rectangular and

measures 88 meters by 113 meters at the top, i.e. a bit larger

than a football field. The water depth is 16 meters, of which

approx. 12 meters go below the natural ground level and 4

meters are established by embankments of the excavated soil at

the perimeter. As mentioned above the total volume of water is

75,000 m

3

.

Early in the design process the slope of the sides was chosen

to 1:2 which in a practically view is the steepest possible

inclination for the installation works of the liner. This

corresponds to an angle of 26.6° against horizontal level. Figure

4 shows a stylized cross section of the pit.

Figure 4. Stylized cross section of the PTES in Marstal.

A site investigation has been performed prior to the design

phase. The investigation consisted of 10 borings, of which two

borings in the centre were taken to 25 meters depth and 8

borings at the perimeter of the excavation were taken to 13

meters depth. The borings were performed as traditionally

geotechnical borings with soil sampling, in-situ tests and

installation of standpipes at adequate depths.

The investigation showed a thin layer of top soil covering

various glacial deposits of primarily clay till and glacially

relocated marine clay of interglacial origin (Cyprina Clay). At

the northern side three meters of melt water sand were covering

the clay. Besides, stripes and zones of melt water sand and sand

till were found, apparently randomly in the clay.

In a geotechnical matter the marine clay was of special

interest. The clay was of high to very high plasticity with

plasticity index I

P

≈

50 %. The natural water content was w

nat

=

21

–

30 % close to the plasticity limit. A fissured structure was

detected in several samples, presumably caused by shear

stresses during the glacial period and/or passive earth pressures

at the end of the glacial period.

The clay deposits were generally stiff to very stiff. Field vane

tests showed undrained shear strength c

fv

between 250 and >700

kPa, thus with a slightly softened zone near the surface.

The effective strength parameters in the clay were estimated

from a priori knowledge of similar soils. The characteristic

value of the angle of friction of the marine clay was estimated to

φ ≈ 20° and of the clay till to φ ≈ 30°

with mean values

approximately 5 degrees higher. Some effective cohesion in the

clay must be expected, but according to Danish calculation

practice

the cohesion was limited to c’ = 20 kPa in unfissured

clay and c’ = 0 kPa in fissured

clay (on the safe side for

decreasing stress level).

Standpipes had been installed at differing depths, separated by

bentonite sealing materials. Groundwater levels were measured

at very varying depths between a few meters depth and large

depth (below excavation level). These measurements are

assumed to be variably ground water build-ups depending on

precipitation and season, whereas a stable ground water table in

a primary aquifer is at large depth.

4 CONSIDERATIONS FOR THE CONSTRUCTION

Establishment of a PTES at the actual site was subject to four

geotechnical concerns: the excavation stability, the groundwater

and soil handling during the construction phase and the long

term consequences of thermal influence on deformations in the

operational phase.

4.1

Excavation stability

The stability of the excavation sides was to be sufficient during

the construction phase. Provided that the ground water issue

was handled, it was evident that a quickly performed excavation

and refilling with water would be advisable as the clay would be

stable in the short term undrained condition. On the other hand,

calculations based on long term drained strength parameters

showed unstable slopes in the marine clay, especially when

adding prescribed safety factors according to Eurocode 7.

The period from starting excavation until fully filling the pit

with water was planned to last 6½ months. One month had to be

reserved the liner work, and as the available capacity for filling

the pit with water was limited to 50 m

3

/h the filling would itself

take two months.

Undrained conditions were evaluated to last at least one

month, but exceeding this period by several months caused

severe considerations of the time for developing drained

conditions and consequently collapses due to unstable slopes. It

was evaluated that further tests and evaluations would not

improve this engineering judgement significantly, and therefore

the stability had to be evaluated for drained conditions.

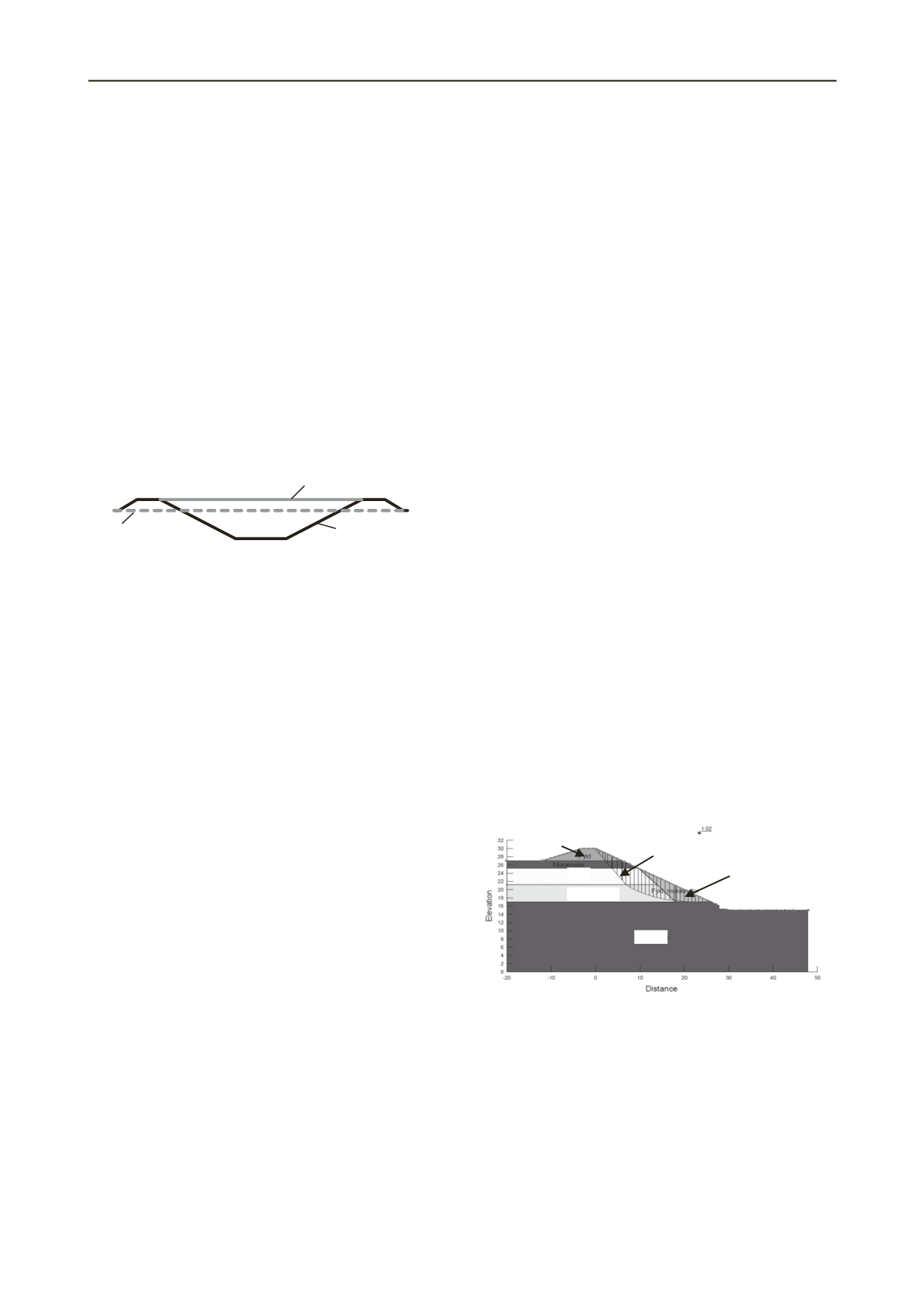

Introducing less steep slopes than 1:2 was not an option, but a

series of slope stability calculations based on different cross

sections showed that it was possible to establish stable slopes of

1:2 by replacing layers of the marine clay until certain depths

with sand or even clay till, see figure 5, forcing the rupture line

at greater depth to involve more stable materials. The

replacement of the marine clay would increase the volume of

soil to be handled in the project by approximately 15 % which

was acceptable.

During the excavation phase it was decided to abstain from

replacements until indications of failures were observed. This

reduced replacements to an absolute minimum.

Figure 5. Example of slope calculations.

4.2

Groundwater handling

The potential energy loss due to groundwater flow across the

site was evaluated to be very limited.

The groundwater build-ups had to be eliminated to enable dry

excavation and a proper handling of the membrane.

Furthermore groundwater lowering was necessary to prevent

uplift, damages due to seepage from the excavation sides and

sliding of the sides, which especially would be problematic if

the sides were sliding after covering with the membrane.

The circumstance that the bottom of the pit was to be covered

with a membrane implied that the groundwater lowering works

was directed to take place on the outer side of the pit, i.e. at

Slope 1:2

Water

Triangle of removed

clay of high plasticity

Rupture line

Fill

Sand

Marine clay

Clay till

Natural ground level

Insulated lid