3357

Technical Committee 307 + 212 /

Comité technique 307 + 212

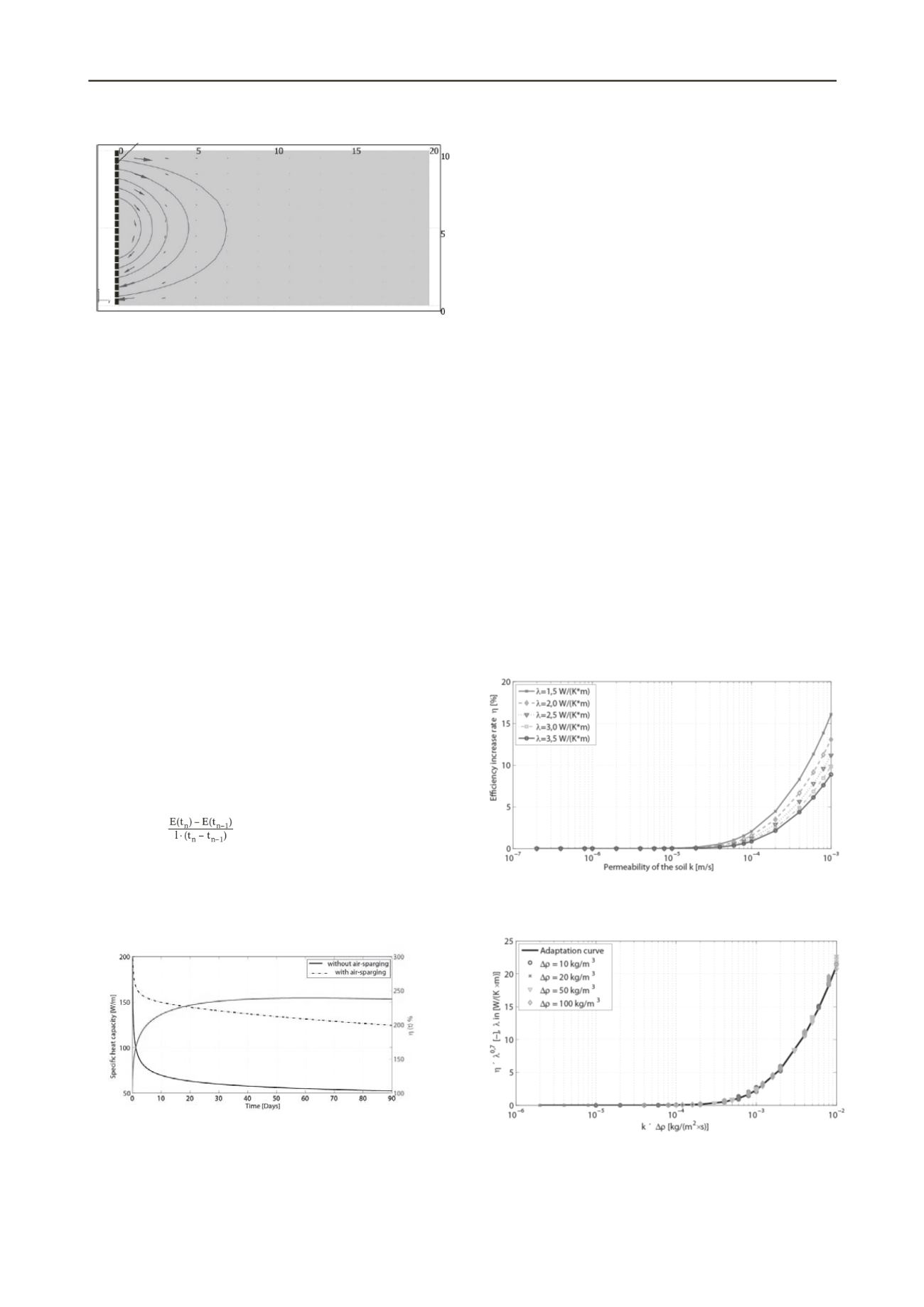

Figure 4. calculated velocity field (arrows) and particle tracing (lines) of

the groundwater around the air-sparging downhole heat exchanger at a

steady rate (Δρ = 10 kg/m³, k = 10

-4

m/s)

3.2

Heat transport

Without the air injection the heat distribution around the

borehole heat exchanger is uniform. The induced groundwater

circulation transports heat away from the well and changes the

shape of the temperature field. In the upper part of the aquifer

the convective heat transport has the same direction as the

conductive heat transport. This increases the heat spreading rate,

which can be seen from the larger heat plume around the well.

In the lower part of the well the groundwater flow direction is

opposite the direction of heat conduction, which slows the heat

spreading rate. At the bottom of the well the groundwater flow

towards the well is so strong that the heat cannot spread

outwards anymore.

The overall heat plume around the well is larger when air

injection is active. This shows that more heat can be transported

into the ground using an air-injection borehole heat exchanger

than using a regular borehole heat exchanger.

3.3

Efficiency of air-injection borehole heat exchanger with

standard parameters

The amount of heat E(t

n

) that the borehole heat exchanger

transports into the ground at the time t

n

equals the integral

product of the temperature change along the entire body of soil

with a soil density of ρ

B

and the specific heat capacity c

B

:

E(t

n

) = ∫ρ

B

c

B

[T(x,y,z,t

n

) – T

0

]dV

(1)

The specific heat abstraction capacity per meter heat exchanger

P

s

(t

n

) is time-dependent:

P

S

(T

N

) =

(2)

In this case l is the length of the borehole heat exchanger.

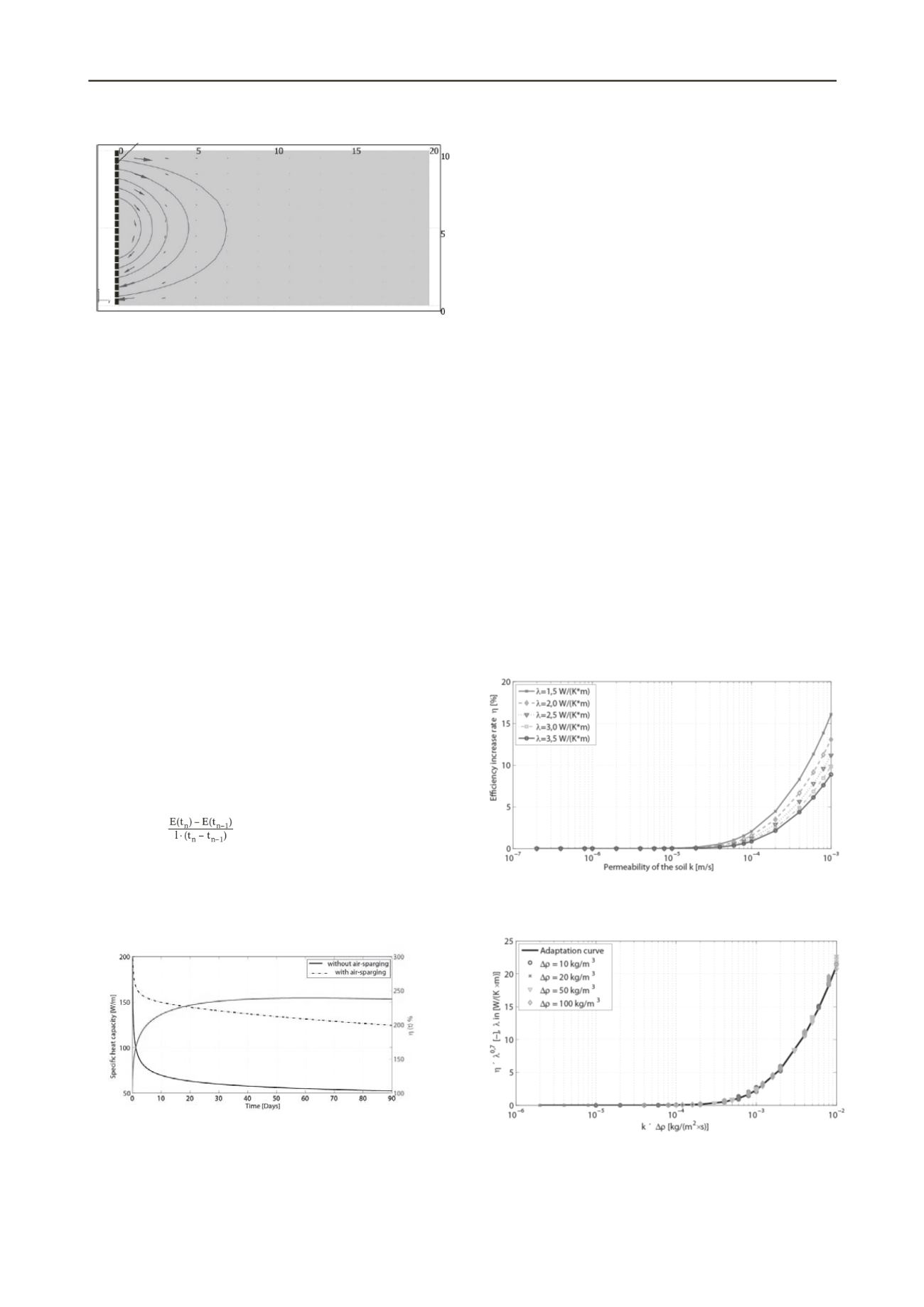

Figure 5 shows the specific heat abstraction capacity as a

function of time, comparing a regular borehole heat exchanger

and one that uses air injection. In both systems the heat

abstraction capacity rapidly reduces within 20 days and changes

only minimally afterwards.

Figure 5. Calculated specific heat capacity with and without air sparging

and efficiency increasing rate of the downhole heat exchanger compared

with normal downhole heat exchanger (Δρ = 10 kg/m³, λ = 2.5 W/(m ·

K), k = 10

-4

m/s)

3.4

Variation calculations

During the calculations three parameters were varied: density of

the air-water-mixture inside the well, heat conductivity and

permeability of the soil.

For low permeabilities of the soil (k < 10

-5

m/s) the heat

abstraction capacity depends only on the thermal conductivity

of the soil. In permeable soils (k > 10

-4

m/s), convection is the

dominant heat transport mechanism and heat conduction has no

influence. In between those parameters the heat abstraction

capacity depends on permeabilty as well as on thermal

conductivity.

The influence of the air injection depends on the ratio

between thermal conductivity and induced convection. The

decisive factor for thermal conductivity is the specific thermal

conductivity of the soil (λ). The convection depends on the

median groundwater circulation velocity (v

z

) that can be

calculated using Darcy’s law.

v

z

= k · i

(3)

Assuming a constant median flow distance the following

relationship can be applied:

v

z

= c · k · Δρ

(4)

Here, c is a constant. The efficiency increasing rate (η) is

therefore mainly dependent on the three parameters k, λ and Δρ.

The relationship between η and λ shows that the five curves in

Figure 6 fit very well when η is mutlilied by λ

0.7

. The

relationship between η, λ, k and Δρ is shown in Figure 7. The y-

axis is labeled η · λ

0.7

and the x-axis is labeled k · Δρ. All

calculated points can be converged towards the adaptation

curve.

Figure 6. Calculated efficiency increasing rate of the air-sparging

downhole heat exchanger against the conductivity and permeability of

the soil (Δρ = 10 kg/m³)

Figure 7. Presentation of the results of the variation calculations and the

adaptation curve, x-axis: k · Δρ, y-axis: η · λ

0.7

This phenomenon offers the possibility of estimating the

efficiency increasing rate when the three parameters λ, k and Δρ

are known.

Figure 5. Calculated specific heat capacity with and without air sparging

and efficiency increasing rate of the downhole heat exchanger compared

with normal downhole heat exchanger (Δρ = 10 kg/m³, λ = 2.5 W/(m ·

K), k = 10

-4

m/s)

3.4

Vari tion calculations

Figure 7.

adaptatio

This ph

efficienc

are kno

Figure 4. calculated velocity field (arrows) and particle tracing (lines) of

the groundwater around the air-sparging downhole heat exchanger at a

steady rate (Δρ = 10 kg/m³, k = 10

-4

m/s)

3.2

Heat transport

Without the air injection the heat distribution around the

borehole heat exchanger is uniform. The induced groundwater

circulation transports heat away from the well and changes the

shape of the temperature field. In the upper part of the aquifer

the convective heat transport has the same direction as the

conductive heat transport. This increases the heat spreading rate,

which can be seen from the larger heat plume around the well.

In the lower part of the well the groundwater flow direction is

opposite the direction of heat conduction, which slows the heat

spreading rate. At the bottom of the well the groundwater flow

towards the well is so strong that the heat cannot spread

outwards anymore.

The overall heat plume around the well is larger when air

injection is active. This shows that more heat can be transported

into the ground using an air-injection borehole heat exchanger

than using a regular borehole heat exchanger.

3.3

Efficiency of air-injection borehole heat exchanger with

standard parameters

The amount of heat E(t

n

) that the borehole heat exchanger

transports into the ground at the time t

n

equals the integral

product of the temperature change along the entire body of soil

with a soil density of ρ

B

and the specific heat capacity c

B

:

E(t

n

) = ∫ρ

B

c

B

[T(x,y,z,t

n

) – T

0

]dV

(1)

The specific heat abstraction capacity per meter heat exchanger

P

s

(t

n

) is time-dependent:

P

S

(T

N

) =

(2)

In this case l is the length of the borehole heat exchanger.

Figure 5 shows the specific heat abstraction capacity as a

function of time, comparing a regular borehole heat exchanger

and one that uses air injection. In both systems the heat

abstraction capacity rapidly reduces within 20 days and changes

only minimally afterwards.

Figure 5. Calculated specific heat capacity with and without air sparging

and efficiency increasing rate of the downhole heat exchanger compared

with normal downhole heat exchanger (Δρ = 10 kg/m³, λ = 2.5 W/(m ·

K), k = 10

-4

m/s)

3.4

Variation calculations

During the calculations three parameters were varied: density of

the air-water-mixture inside the well, heat conductivity and

permeability of the soil.

For low permeabilities of the soil (k < 10

-5

m/s) the heat

abstraction capacity depends only on the thermal conductivity

of the soil. In permeable soils (k > 10

-4

m/s), convection is the

dominant heat transport mechanism and heat conduction has no

influence. In between those parameters the heat abstraction

capacity depends on permeabilty as well as on thermal

conductivity.

The influence of the air injection depends on the ratio

between thermal conductivity and induced convection. The

decisive factor for thermal conductivity is the specific thermal

conductivity of the soil (λ). The convection depends on the

median groundwater circulation velocity (v

z

) that can be

calculated using Darcy’s law.

v

z

= k · i

(3)

Assuming a constant median flow distance the following

relationship can be applied:

v

z

= c · k · Δρ

(4)

Here, c is a constant. The efficiency increasing rate (η) is

therefore mainly dependent on the three parameters k, λ and Δρ.

The relationship between η and λ shows that the five curves in

Figure 6 fit very well when η is mutlilied by λ

0.7

. The

relationship between η, λ, k and Δρ is sho n in Figure 7. The y-

axis is labeled η · λ

0.7

and the x-axis is labeled k · Δρ. All

calculated points can be converged towards the adaptation

curve.

Figure 6. Calculated efficiency increasing rate of the air-sparging

downhole heat exchanger against the conductivity and permeability of

the soil (Δρ = 10 kg/m³)

Figure 7. Presentation of the results of the variation calculations and the

adaptation curve, x-axis: k · Δρ, y-axis: η · λ

0.7

This phenomenon offers the possibility of estimating the

efficiency increasing rate when the three parameters λ, k and Δρ

are known.