3365

Technical Committee 307 + 212 /

Comité technique 307 + 212

Figure 3: General view after assembly and hardening

As the development of the procedure requires many

preliminary tests, the first experiments were conducted with

sand for which time for consolidation and water saturation is

reduced in comparison with fine grained soils.

The sample represented on figure 4 is as following

assembled: firstly, filter plate (see figure 5) is laid in the

encasement and the bored part covered with a filter paper. A

PVC tube is then inserted in the cut-out of the filter plate,

reproducing the use of a tubing casing. Sand is filled around this

PVC tube and saturated from the bottom up. At last, grouting

material is injected and the PVC tube is vertically removed.

Grouting material hardens during 28 days before applying

temperature loads. The assembly procedure has been validated

and improved on base on experiments with reduced dimensions

as related in the previous part.

Figure 4: Sectional drawing of the sample during assembly

Figure 5: Sectional drawing of the filter plate

4.3

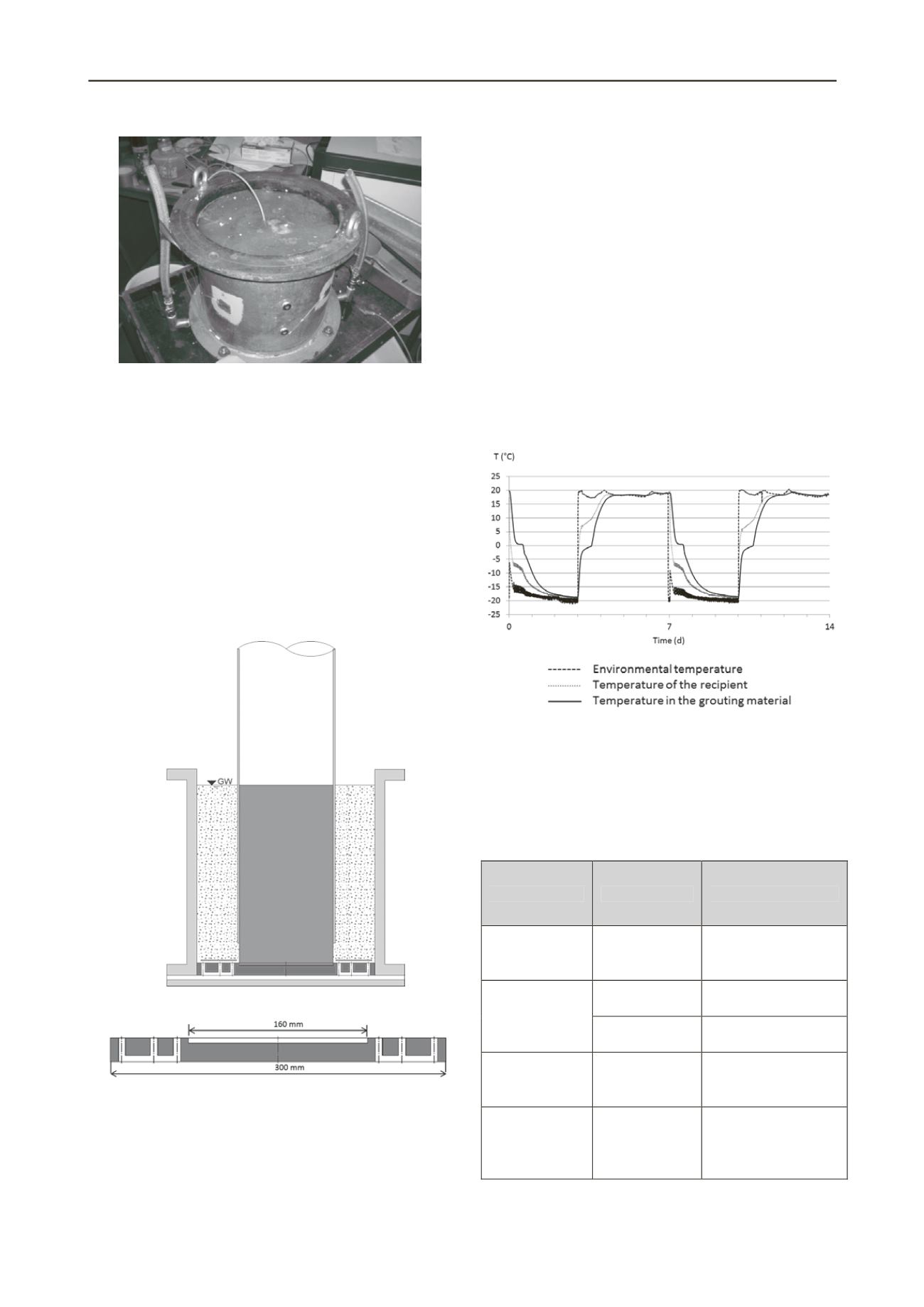

Temperature measurements

In case of a borehole heat exchanger, freeze-thaw cycles are

mostly due to temperature changes inside the pipes. However,

temperature varies during the tests outside the assembled unit in

order to keep homogenous samples for performing unconfined

compression tests. In the procedures referred in part 3 that deal

with other boundary conditions and materials, temperature

varies either between -10 °C and +10 °C or between -20 °C and

+20 °C. The temperature range selected here between -20 °C

and +20 °C is in accordance with the attainable temperatures

ins

6), the

eriod of one freeze thaw cycle is fixed to 7 days. Investigations

described in next part were carried out after two cycles.

ide the pipes of a borehole heat exchanger with an additional

security factor.

Temperature measures are necessary before execution of the

main experiments in order to fix the period of the freeze-thaw

cycles, considering that freezing and thawing processes should

attain a stable phase. A first sensor is used in order to control

the environment temperature, a second sensor measures the

temperature on the border of the encasement and a third sensor

has been brought during the assembly inside the grouting

material. According to those measurements (figure

p

Figure 6: Temperature measurements during freeze thaw cycles on a

aturated sand

of the tests and investigations which were

arried out in the framework of the procedure development is

Table 1: Ty

sample of grouting material and s

4.4

Further investigations

An overview

c

given in table 1.

pes of investigations

Sample

Conditions

Investigations

Grouting material

With freeze-thaw

Temperature measures,

f sand

and watersaturated

sand

cycles

grading curve o

Without freeze

thaw cycles

Grading curve

Blank sample with

watersaturated

sand

With freeze-thaw

cycles

Grading curve

Blank sample with With freeze-thaw

fter

grouting material

cycles

Surface alteration a

each cycle, unconfined

compression test

Blank sample wit

grouting

h

material

(in contact with

water)

With freeze-thaw

cycles

after

each cycle, unconfined

compression test

Surface alteration