3368

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

After the bentonite heating described above, these samples

werekeptat a constant temperature (22 3°C) and constant

humidity (70% relative humidity) until the water contents of

samples stopped changing.

3 SWELLING PRESSURE AND SWELLING

DEFORMATION OF BENTONITES

AFTERSOMETHERMAL EXPOSURE

This study used the experimental apparatus presented in Fig.

2.The maximum capacity and the minimum scale of the load

transducer were 10 kN and 0.0025 kN, respectively. The

maximum capacity and the minimum resolution of the linear

variable displacement transducer (LVDT)were, respectively, 25

mm and 0.002 mm. This study conductedswelling characteristic

experiments of twokinds. The swelling pressure test measured

the bentonites’ swelling pressure as water was supplied to the

confined bentonite specimen. The swelling deformation test

measured the relationbetween the axial swelling deformation

and the time from the start of water supply. Test

proceduresweredescribed in an earlierarticle (Komine et al.,

2009).

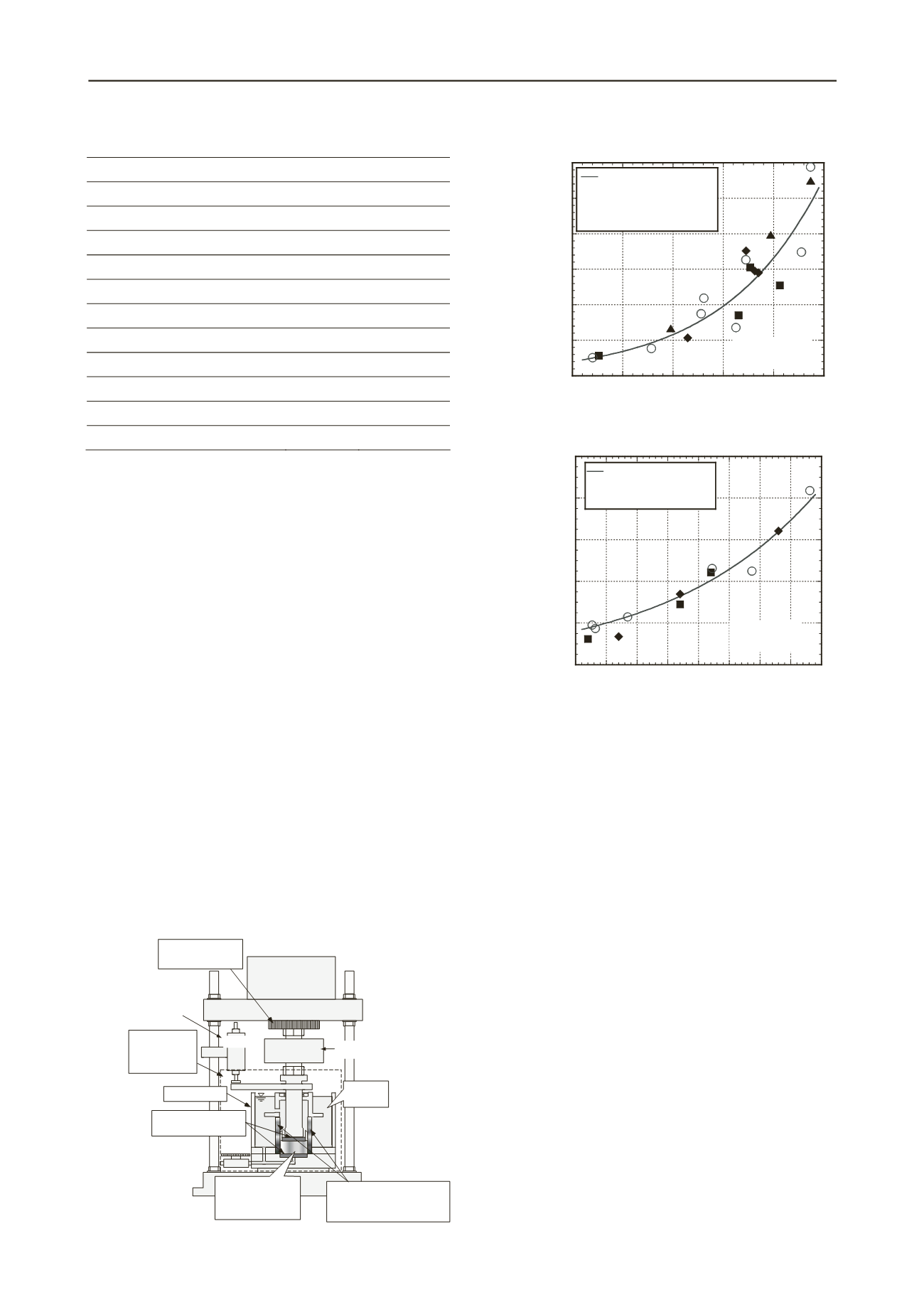

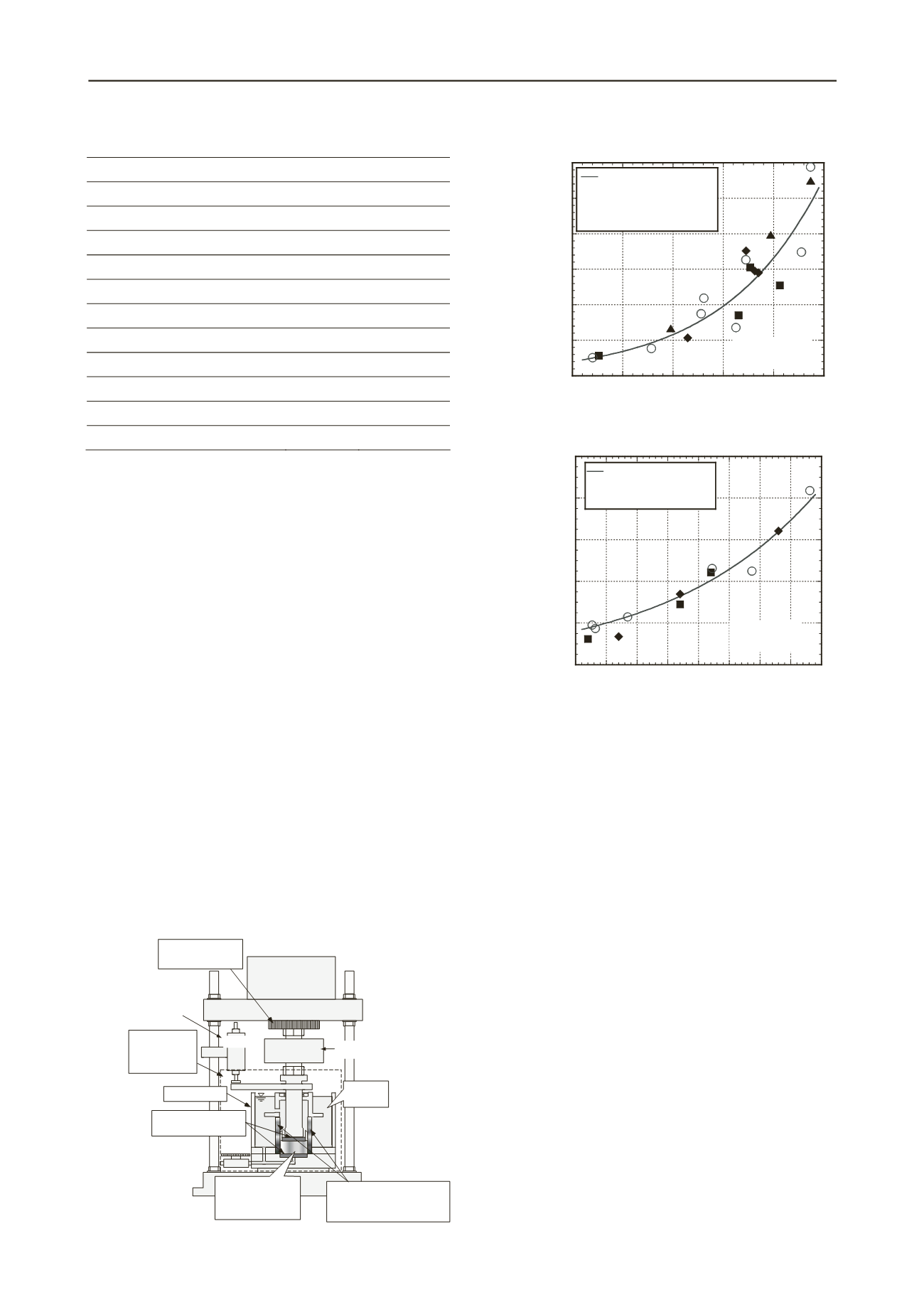

Figure 3 portrays the relation between maximum swelling

pressure and the initial dry density of bentonites’ thermal

exposureduring swellingpressure tests. This figureshows that

the influence of thermal exposureon swelling pressure

characteristics of both bentonites is slight, provided that

theheating temperature is less than 130°C and that the heating

duration is less than 120 days.Regardingresultsobtained for

calcium-type bentonite C depicted in Fig. 3(b), almost no

influenceof

thermal

exposureon

swelling

pressure

characteristics is shown for1.37–1.53 Mg/m

3

initial dry density.

However, a slightinfluenceof thermalexposure is apparentat

1.22–1.27 Mg/m

3

.

0

1000

2000

3000

4000

5000

6000

1.4 1.5 1.6 1.7 1.8 1.9

Maximum swelling pressure, P

smax

(kPa)

Initial dry density,

d0

(Mg/m

3

)

○

: No heating

▲

: 60 degree, 28 days

◆

: 130 degree, 28 days

■

: 130 degree, 120 days

Bentonite A

(Kunigel-V1)

(a) Bentonite A

0

2000

4000

6000

8000

10000

1.2 1.25 1.3 1.35 1.4 1.45 1.5 1.55 1.6

Maximum swelling pressure, P

smax

(kPa)

Initial dry density,

d0

(Mg/m

3

)

○

: No heating

◆

: 130 degree, 28 days

■

: 130 degree, 120 days

Bentonite C

(Kunibond)

(b) Bentonite C

“No heating” in the legend denotes experimentally obtained results for

bentonite with no thermal exposure. The temperature in the legend is

the heating temperature by dryingoven. The days in the legend show

the heating duration.

Figure 3. Relationbetween maximum swelling pressure and initial dry

density of bentonites A and B withthermal exposure.

Table 1. Fundamental properties of bentonites A and C

Bentonite

A

C

Type

Sodium

Calcium

Density of soil particle(Mg/m

3

)

2.79

2.71

Liquid Limit (%)

458.1

128.7

Plastic Limit (%)

23.7

38.4

Plasticity index

434.4

90.3

Montmorillonite content (%)

57

84

Cation Exchange Capacity (meq/g)

1.166

0.795

Exchange Capacity of Na

+

(meq/g)

0.631

0.119

Exchange Capacity of Ca

2+

(meq/g)

0.464

0.585

Exchange Capacity of K

+

(meq/g)

0.030

0.019

Exchange Capacity of Mg

2+

(meq/g)

0.041

0.072

Figure 4 shows the relation between maximum swelling

strain and initial dry density of sodium-type bentonite A at

vertical stresses of 1000 kPa and 500 kPa. Results in this

figureshow that maximum swelling strain increases linearly as

theinitial dry density increases. For the sodium-type bentonite A,

the swelling deformation property of bentonite after thermal

exposure is almost unchangedunder 1000 kPa vertical stress.

However, the swelling deformation property of bentonite

isgreatlyreduced for heating at 90–130°C fora 365-day heating

duration under conditions of 500 kPa vertical stress, as

portrayed in Fig. 4(b). Those results indicate that the thermal

influence to swelling deformation characteristics of sodium-type

bentonite A is dependent onthe vertical stress condition. The

influences of thermal exposureon swellingdeformation decrease

for high vertical stresssuch as 1000 kPa. Thisdiscussion shows

agreement with previously presenteddiscussionindicating that

swelling pressure characteristics of bentonite Ashowalmost no

change according to thermal exposure, as depicted in Fig. 3(a)

and previously reportedexperimentally obtained results

(Komine and Ogata, 1998) showing thatswelling deformation

Load

transducer

Distilled

water

Compressed air

cylinder for

loading

Clamp for fixing

the piston

LVDT

Porous metal and

nonwoven filter

Acrylic cell

Swelling cell

(Inside of

broken lines)

Specimen

Diameter 28 mm

Height 10 mm

316L stainless steel ring

Inner diameter 28 mm

Height 50 mm

Maximum capacity = 10 kN

Minimum scale = 0.0025 kN

Maximum capacity = 25 mm

Minimum scale = 0.002 mm

Figure 2. Experimental apparatus.