3356

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

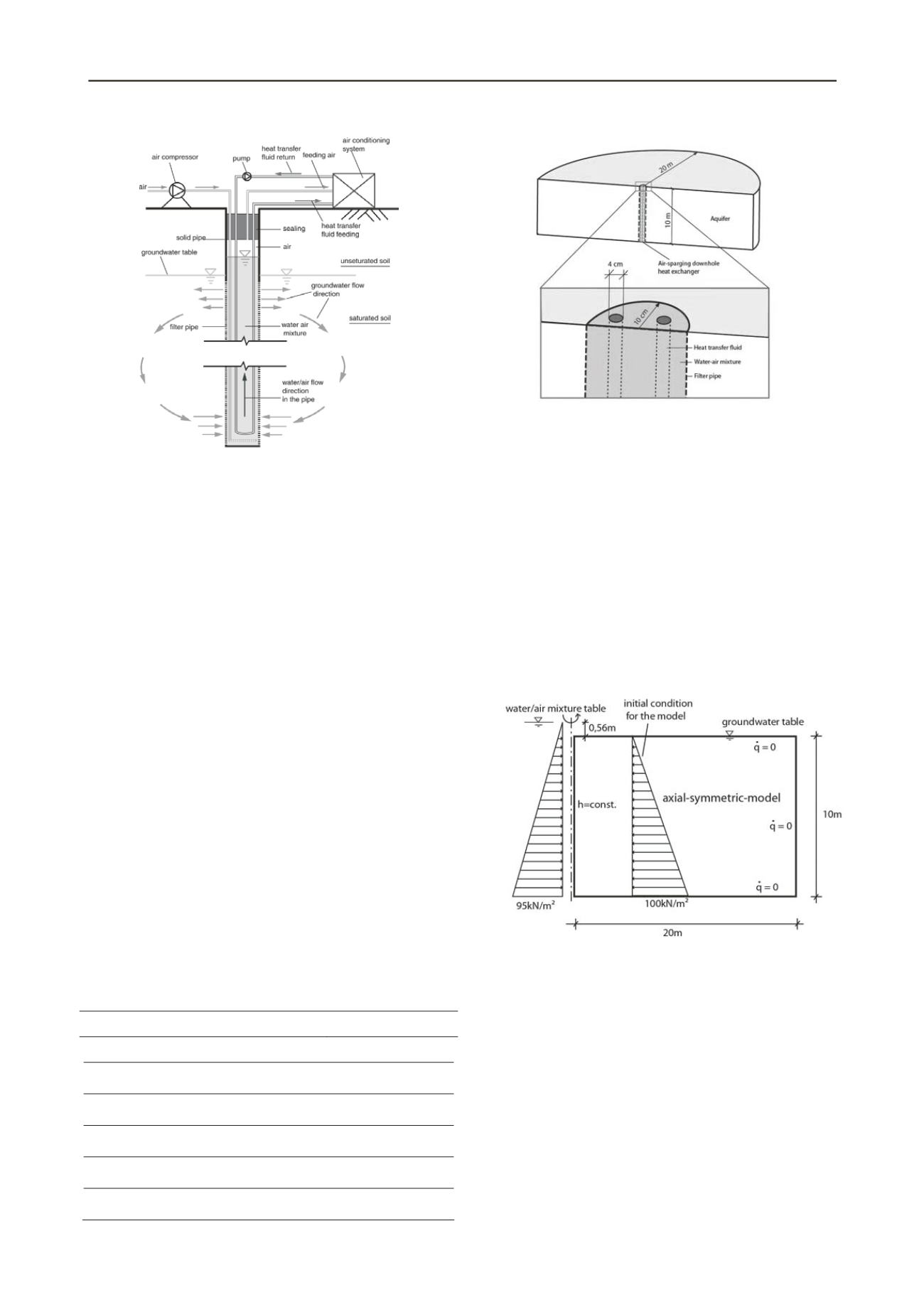

Figure 1. Combination of an air-sparging downhole heat exchanger with

an air conditioning system

The combination of a borehole heat exchanger with an air-

injection well increases the performance of the system shown in

Figure 1 in three ways. First, the groundwater cools the air

before it reaches the air conditioning system, therefore reducing

the energy necessary for the A/C. Second, the vertical flow of

the air-water mixture inside the well increases the heat

exchange between the heat pipes and the groundwater

(Gustafsson, Westerlund and Hellström 2010). And third, the

circulation of the groundwater increases the heat convection in

the subsurface which leads to a higher efficiency of the overall

system.

2.2 Numerical model

The simulations of the air-injection borehole heat exchanger

were done with the finite-element program COMSOL

multiphysics. A three-dimensional model was used. The

geothermal system has a radius of 10 cm and the thickness of

the aquifer is 10 m. Prior to the air injection there is no

groundwater flow. Four pipes are introduced into the well. The

induced groundwater flow, as well as the convective heat

transfer are modeled using the FEM. Flow inside the well itself

and inside the heat pipes is neglected. The pipes are simplified

represented as cylindrical heat sources with constant

temperatures.

The aquifer is assumed to consist of homogeneous sand.

Several variations concerning heat conductivity, permeability of

the soil and density of the air-water-mixture are simulated with

the model shown in Figure 2. The used thermal and hydraulic

parameters are listed in Table 1. The bold values can be

considered to be standard parameters.

Table 1. Applied thermal and hydraulic parameters of the soil and the

air-water-mixture

Thermal conductivity sat. soil (W/(m · K))

1.5/2.0/

2.5

/3.0/3.5

Specific heat capacity sand (J/(kg · K))

800

Effective porosity (-)

0,25

Density of water (kg/m³)

1000

Density of air-water-mixure (kg/m³)

900/950/980/

990

Density of sand grains (kg/m³)

2650

Permeability (m/s)

10

-7

~

10

-4

~ 10

-3

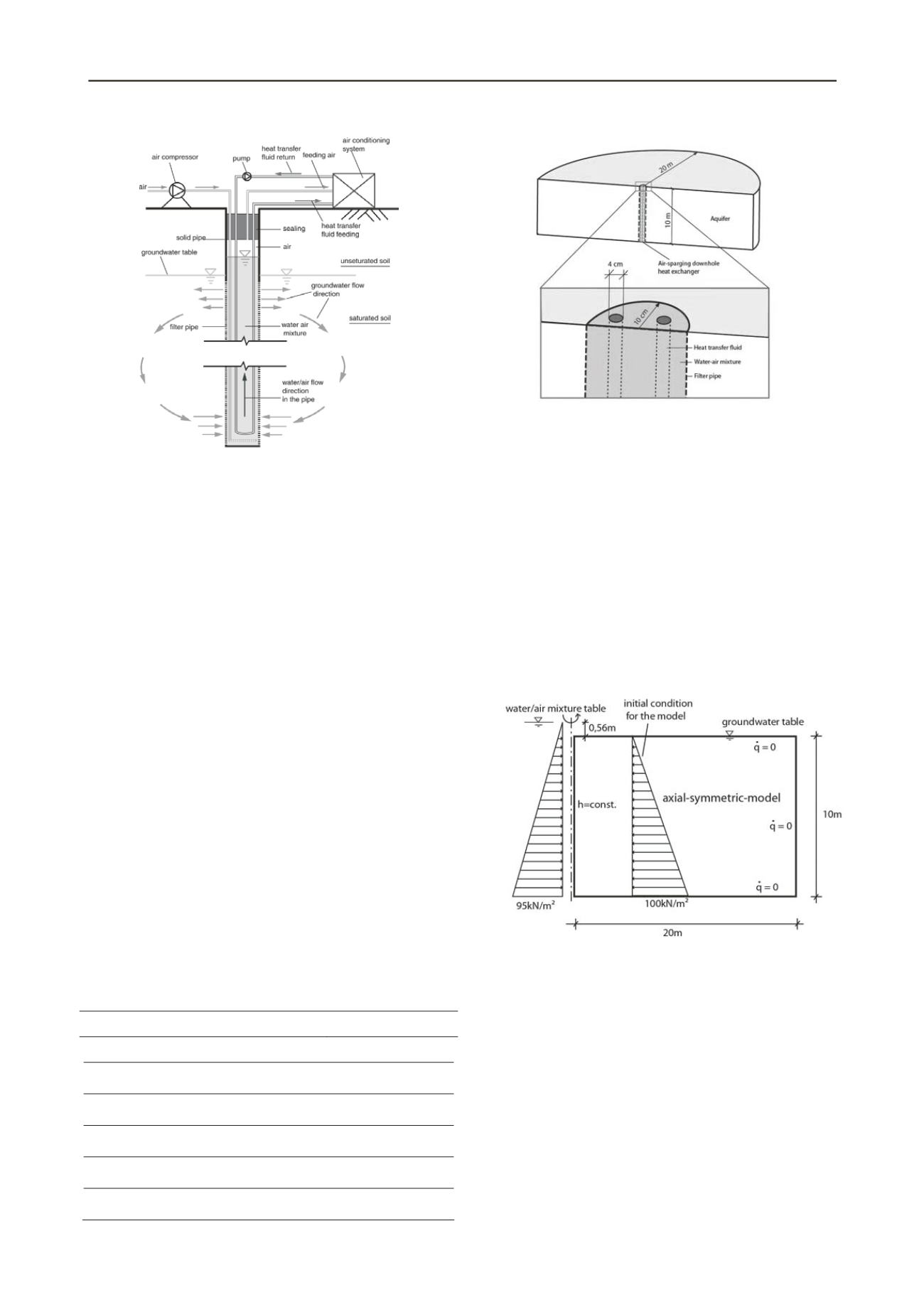

Figure 2. Numerical model for the simulation of an air-sparging

ownhole heat exchanger

d

The induced groundwater flow increases heat transport through

convection. All calculations assume that the hydraulic and

thermal parameters of the soil are temperature independent.

This means that groundwater flow is not influenced by heat

transport. Both mechanisms – groundwater flow and heat

transport – are considered separately. The first step is to

simulate the groundwater flow until stationary conditions are

reached. The results are saved and in the second step the results

are superimposed by the heat propagation in the soil in 90 days.

Before the air injection the well experiences a hydrostatic

pressure distribution. As a boundary condition for the

simulation the wall of the well experiences a constant pressure

distribution from the air-water-mixture, which has a smaller

density but a higher water level than the surrounding

groundwater. Boundary conditions are shown in Figure 3 (Ma

and Grabe 2011).

Figure 3. Boundary and initial conditions of the model for calculation of

the groundwater circulation caused by air-sparging with an air-water-

mixture with a density of 990 kg/m³

3 NUMERICAL RESULTS

3.1

Groundwater flow

The groundwater flow induced by the air injection is calculated

until stationary conditions are reached. The arrows in Figure 4

show the calculated velocity vectors of the groundwater. The

highest velocity (approx. 1.2 · 10

-5

m/s) can be found close to

the well. With increasing distance to the well the velocity

decreases. The flow lines show the groundwater circulation. The

bold parameters from table 1 achieve a water exchange rate

between well and soil of about 0.06 m³/h.