3352

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

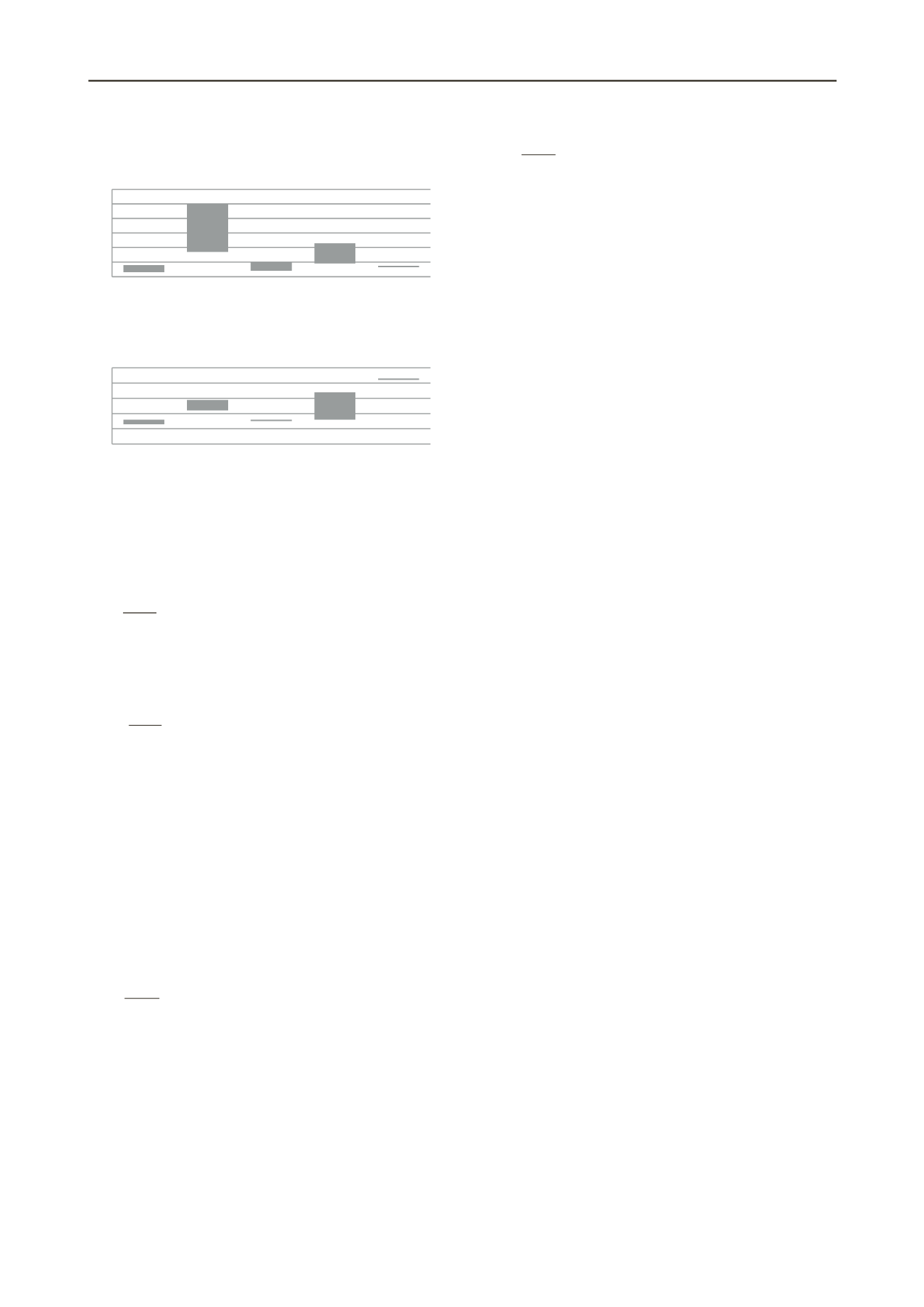

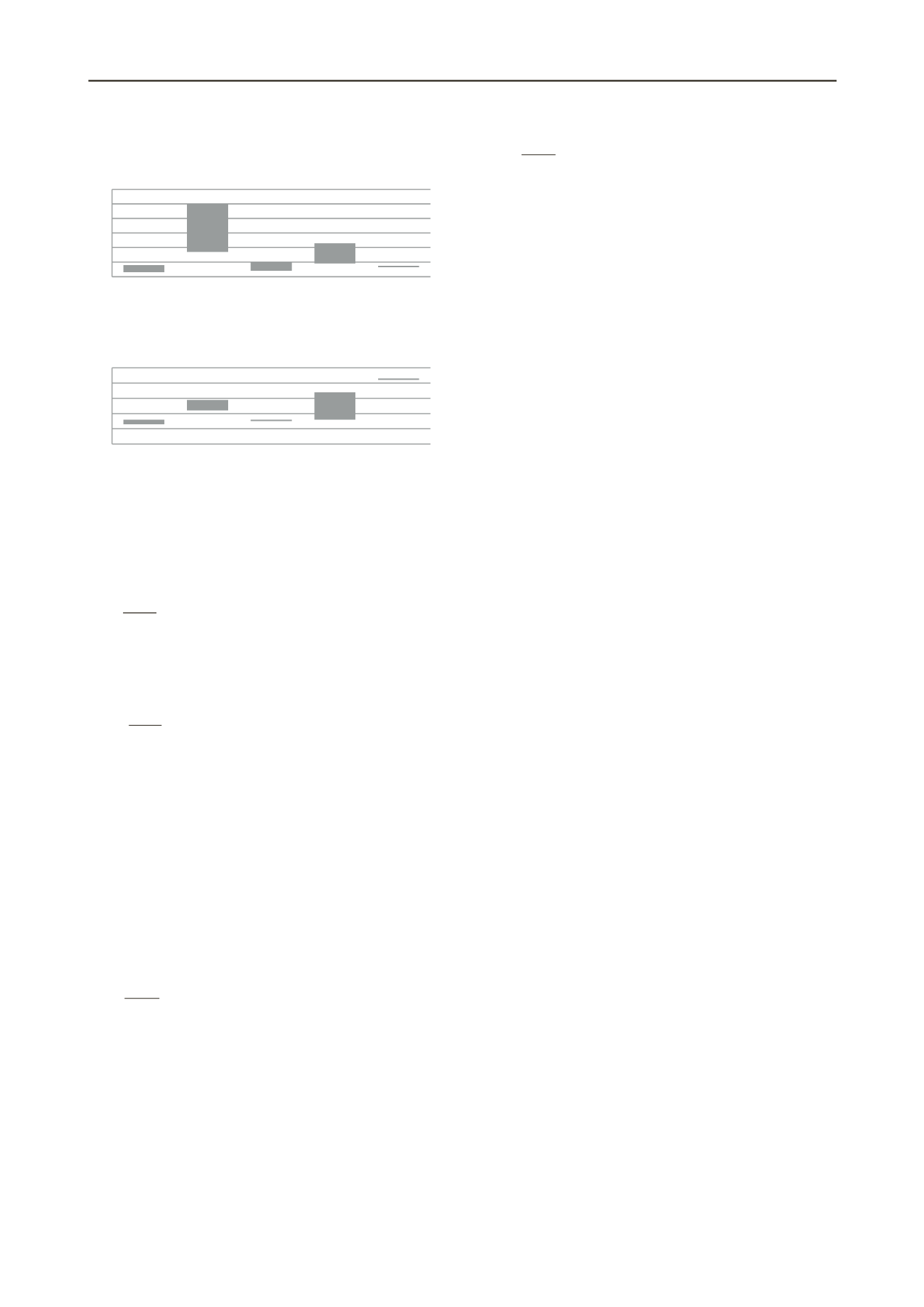

Ingenieure 2004). The figures show that the natural water

content of the soils is very important for the thermal parameters.

Figure 2. Typical values of thermal conductivity i

n W/(m∙K)

.

Figure 3. Typical values of volumetric heat capacity in MJ/(m

3

∙K)

.

The range of operational temperature must be as large as

practically possible, as the range will impact on the necessary

volume of storage.

Large seasonal thermal energy storages may be established as

one of the following systems: TTES, PTES, ATES or BTES.

The TTES (Tank Thermal Energy Storage) system consists of

an insulated steel tank filled with water and is widely used in

the short-term regulation of the heat consumption against the

heat production at heating plants. A volume of 1,000

–

5,000 m

3

is often adequate for most Danish medium-sized district heating

systems. Typically operational temperatures are T = 30 - 90°C,

i.e. ΔT ≈ 60°C

.

The PTES (Pit Thermal Energy Storage) system is an

excavated pit, which is lined by a membrane and filled with

water. Operational temperatures are typically 30 - 90°C. The

upper temperature affects the lifetime of the membrane and long

term exposure of the upper temperatures therefore has to be

avoided. The permissible level and exposure time of the upper

temperature is a trade-off between the lifetime of storage and

storage capacity. Usually the storage is not insulated towards

the soil, as the energy loss through these areas is acceptable low

under certain circumstances. The top of the storage

–

the water

surface

–

is exposed to alternating climate conditions, including

cooling by wind, which requires insulation. The insulation may

be floating on the water or carried by a supporting system. For

larger storages a PTES system is very cost-effective. In

Denmark a few pilot PTES plants are in use with volumes up to

10,000 m

3

, but larger plants are under construction, as this

article describes.

The ATES (Aquifer Thermal Energy Storage) system stores

the heat in a groundwater aquifer. The extend and

characteristics of the aquifer must be well-known as the

groundwater is pumped from a number of wells and

–

after

passing a heat exchanger to impact or extract heat energy -

infiltrated into the aquifer in another part of the aquifer.

Typically operational temperatures are 5 - 30°C

with ΔT ≈

25°C, i.e. the volume of water must be larger than for the above

mentioned storages. This type of plant requires a groundwater

aquifer with high permeability. In Denmark most of the

drinking water supply is based on groundwater, and this implies

that large ATES’s will not be allowed in areas with

special

interest of drinking water supply. A

growing number of ATES’s

have though been established, mainly initiated by a need of

cooling during summertime of large building complexes.

The BTES (Borehole Thermal Energy Storage) system

consists of a large number of boreholes with loops of heat pipes

installed. The heat is transferred to the soil by circulating brine

in the heat pipes and vice versa when the heat is to be

consumed. As operational temperatures are 20 - 60 °C

, i.e. ΔT ≈

40°C, and the heat capacity of soil is small compared to water, a

larger soil volume is needed than for storages based on water.

This is compensated as the boreholes usually go to 50

–

100

meters depth. The thermal conductivity of soil is moderate, and

the response of the storage is thus relatively slow. At present

only one pilot plant has been established in Denmark at a

district heating plant.

2 SEASONAL ENERGY STORAGE IN MARSTAL

Marstal is a town with 2400 citizents on the Danish island

Aeroe. For many years the district heating system in the city of

Marstal has been based on oil fuels. During the last decade

Marstal District Heating has turned towards 100 % renewable

energies, so that from 2012 a solar heat system

–

covering

33,000 m

2

solar heat panels on 10 hectares of land

–

will

produce more than 50 % of the heat consumption and the rest

will come from biomass energy. At present the plant is the

largest solar heat plant for district heating in the world, but this

ranking will presumable only be held for a short period.

Marstal has been a Danish pioneer in thermal energy storage.

In 1998 a 3,000 m

3

combined gravel and water pit has been

built, and the plant was followed by a 10,000 m

3

PTES in 2003.

Calculations have shown that the requested large percentage of

solar heat coverage in Marstal needs a volume of 75,000 m

3

water in which case

all

surplus solar energy produced during

summertime can be stored until winter. This volume is

established by a PTES plant. The project is economically

supported by the European Union (EU).

Performing a PTES has some preferred technical conditions in

relation to an economic design in regards of both the

establishment phase and the operation phase as described in the

following:

The pit

must

be performed as an open pit without using e.g. a

framing sheet pile wall which would increase the cost

considerably. To minimize excavation costs the ground must

consist of soils which can be excavated and handled by

traditionally methods and with no significant groundwater

handling.

To reduce heat loss into the air the pit must be covered by

insulation with guaranteed resistance to temperatures up to

90°C for the lifetime of the storage. The top insulation and the

bottom membrane (in this case a 2.5 mm HDPE liner) are some

of the most expensive parts in a PTES and the area of the

insulation must consequently be minimized.

Dry soils insulate better than moist or saturated soils, and

moreover groundwater may introduce unwanted heat loss if

heated groundwater flows across the site. Therefore, the

groundwater level must be at a convenient depth below the

bottom of the pit, alternatively a higher groundwater level is

tolerated, but in that case no significant groundwater flow

across the site is allowed.

The loss of heat is reduced to a theoretical minimum when the

pit has a spherical shape. This is not obtainable in practice and

excavation is often performed as an upturned frustum of

pyramid. The width must be minimized, for which reason the

slopes of the sides of pyramid must be as steep as practical

possible. This reduces moreover the area of the expensive top

insulation.

In order to establish soil balance in the project the excavated

soil is to be used in building up embankments around the

0

1

2

3

4

5

6

Sand, dry

Sand,

saturated

Clay/silt, dry Clay/silt,

saturated

Water

0

1

2

3

4

5

Sand, dry

Sand,

saturated

Clay/silt, dry Clay/silt,

saturated

Water