3345

Technical Committee 307 + 212 /

Comité technique 307 + 212

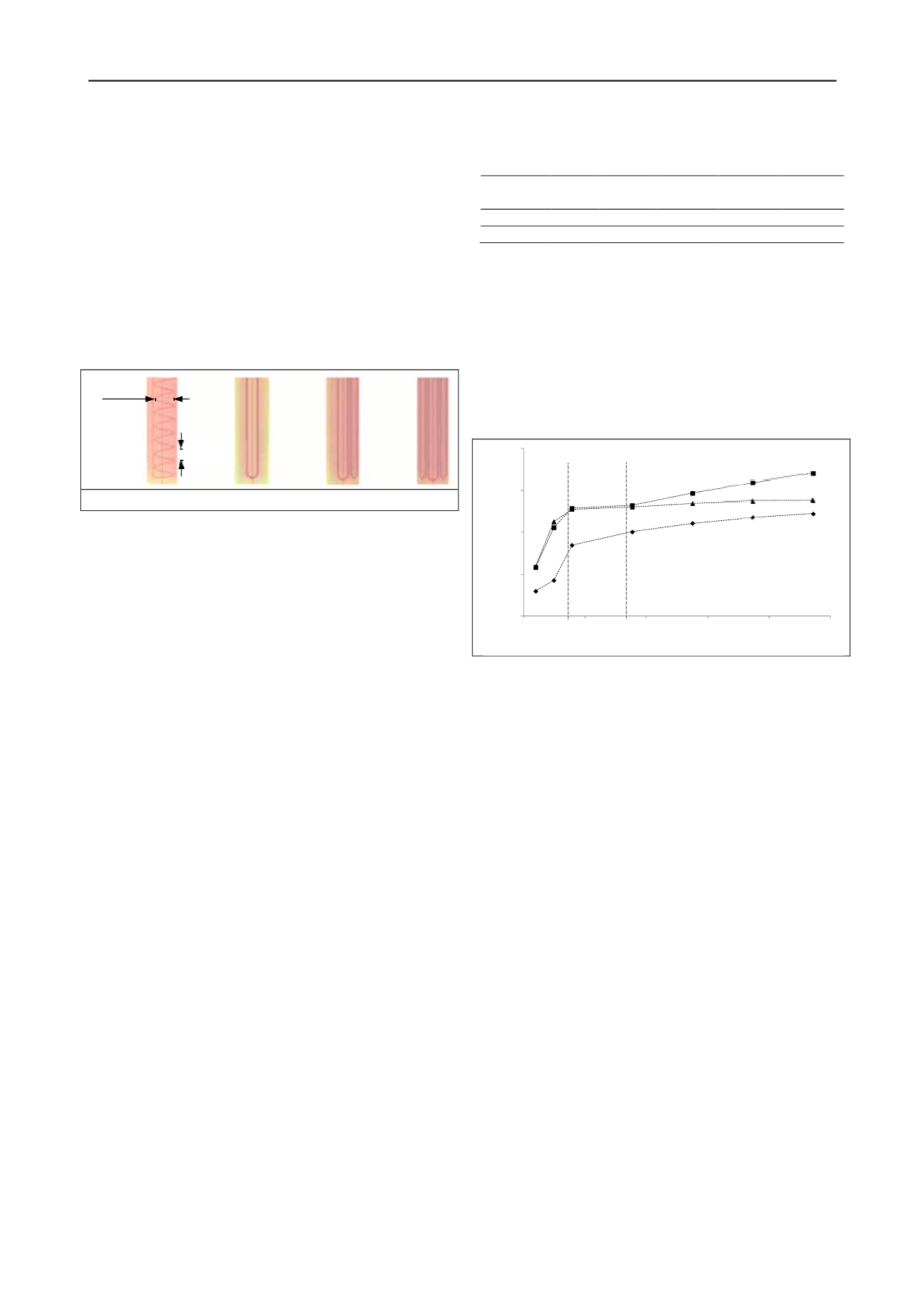

HDPE pipes are 0.025 m in diameter and with a 0.003 m wall

thickness. The spiral configuration consists of an inlet pipe with

a 0.3 m spiral major diameter and axial pitches which are

varied, sequentially, between 0.2 m to 1 m; and a straight outlet

pipe (Figure 3-a). Consequently, different pipe lengths are

modelled to investigate the effects on heat extraction rate.

Numerical results obtained from the above modelling are

compared to the results from 0.46 m diameter, 30 m long GHEs

with single, double and triple U-pipes, 0.025 m in diameter

embedded within, which render the same pipe lengths as the

ones in the spiral configurations (see Figure 3-b through -d).

The same assumed constant material properties are shown in

Table 1. The FEM mesh in these model follows the same mesh

density distribution as shown in Figure 2.

(a) (b) (c) (d)

Figure 3. Detail of GHEs with (a) spiral pipe, (b) single U-pipe; (c)

double U-pipe, (d) triple U-pipe.

2.2

Initial and boundary conditions

A depth dependent temperature, varying between 8.7

°

C at the

ground surface and 18.6

°

C for the first 10 m below the ground

surface, is applied over the entire model (the GHEs and the

ground) as initial and far-field boundary condition. Below this

relatively thin layer and from about 10 m to 30 m below the

ground surface, a constant temperature of 18.6

°

C is applied to

the rest of the model. To account for the thermal interaction

between conductive and convective heat transfer, the inlet

temperature and fluid flow rate are also specified as boundary

conditions. The simulations are run in heating mode, that is,

whilst extracting heat from the ground. For simplicity, a typical

inlet temperature of 5ºC is prescribed in the inlet pipe(s) of the

modelled GHEs. For the fluid flow simulation inside the pipes,

a no slip boundary condition is applied on the pipe walls, in

other words, the water velocity on the pipe wall is set to zero;

and a reference atmospheric pressure is set in the outlet pipe(s)

for the purpose of forced convection.

3 RESULTS

In this section a brief summary of the model validation is

presented together with the results of the numerical simulations

of the various ground loop configurations and fluid flow rates.

3.1

Model validation

Numerical results obtained from the transient study of GHE

with a single U-pipe were validated against analytical solutions

that are based on Infinite Line Source Model (ILSM), Finite

Line Source Model (FLSM) and Cylindrical Source Model

(CSM). Details of these solutions can be found elsewhere

(Bernier 2001, Deerman 1990, Jun

et al.

2009, Lamarche and

Beauchamp 2007, Marcotte and Pasquier 2008). As an example,

Table 2 summarises the results in terms of heat extraction rate q

and outlet pipe(s) temperature T

out

for the case of a 30 m long

GHE, with 0.025 m diameter single U-pipe and water flow rate

of

∼

14.5 l/min after 120 hrs of operation. Numerical results are

in good agreement with the FLSM, which is the most reliable

model among the previously mentioned models. The numerical

results are also within the range of measurements reported for

full scale experiments (Banks 2008, Gao

et al.

2008, Hamada

et

al.

2007, Miyara

et al.

2011).

Table 2 Comparison between analytical and numerical solutions.

Parameter

ILSM

FLSM

CSM

Field

data

This

work

q [W/m]

30.67

44.93

32.14

10-60

48.87

T

out

[

°

C]

5.93

6.36

5.97

-

6.48

3.2

Numerical results and discussion

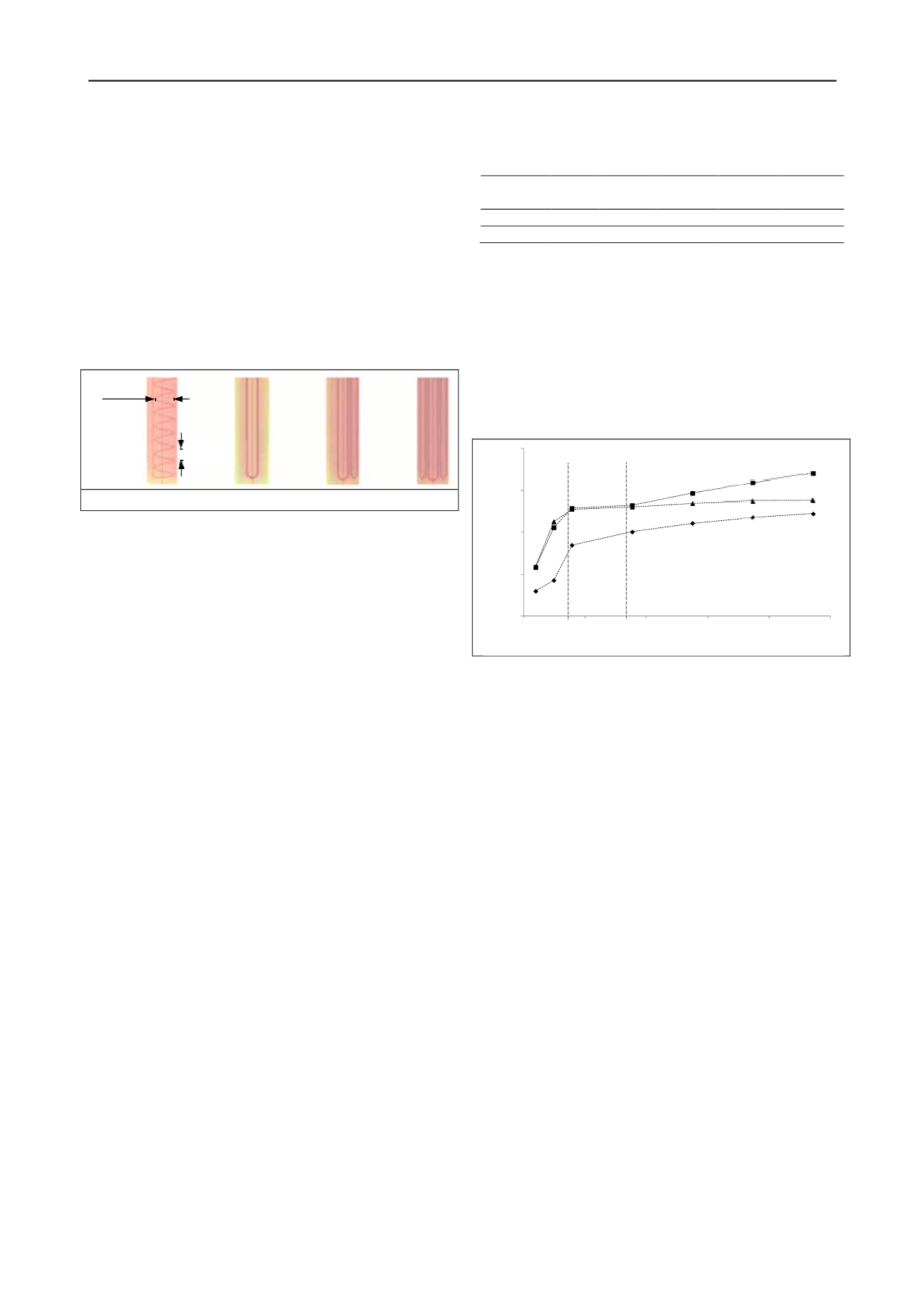

With the numerical model validated for the single U-pipe case,

other GHE pipe configurations were then examined: the double

U-pipe and the double cross U-pipe. Cross sections of all small

diameter GHEs were shown in Figure 1. We studied the effects

on the thermal performance of these GHE configurations caused

by variations of water flow rate. Figure 4 shows a summary of

the numerical results for GHEs with single, double and double

cross U-pipes, expressed as the total average heat extraction of

each GHE per meter depth of borehole.

Figure 4. Heat extraction rate as a function of fluid flow rate.

As the average water flow rate increases in the pipe, heat

extraction rate first tends to increase at a high rate for all GHE

configurations considered here. However, above a flow rate of

approximately 5.30 l/min (u = 0.18 m/s) the flow becomes

turbulent and the increase in the heat extraction rate with flow

(or Reynolds number) slows down in comparison with the

laminar regime. Thus higher flow rates, do not necessarily

results in significant increase in system’s efficiency and the rate

of increase declines with Reynolds number beyond a certain

threshold. The addition of a second U-pipe to a single U-pipe

configuration does not double the thermal performance but

achieves between about 40% to 90% additional performance,

depending on the volume of the water in contact with the

ground heat source/sink. Nevertheless, savings may be achieved

in terms of drillings costs, given the reduction in the total

number or length of GHEs than would be needed with a single

U-pipe. The comparison of double U-pipe and double cross U-

pipe configurations shows that GHEs with double U-pipe

perform about up to 23% better while the water fluid flow is in

turbulent regime, and has nearly the same performance in

laminar regime, for the pipe separations studied here.

For the case of large diameter GHEs, Figure 5 shows the

effect of axial pitch in GHEs with spiral pipes. The figure shows

that smaller axial pitches, which render longer pipe length,

result in higher thermal performance since there is larger

contact area between the water and the ground heat source/sink.

Comparing the thermal performance between large diameter

GHEs with spiral pipes and U-pipes, Table 3 shows that for a

given total water flow rate of 14.5 l/min in each GHE, and

borehole length and diameter, GHEs with same pipe length

embedded within have nearly the same thermal performance

regardless of pipe geometry specifically when dealing with

more than one U-pipe (i.e., spiral and multiple U-pipes with

0.14 m of pipe separation). Therefore, GHEs with multiple U-

pipes instead of spiral pipes would be recommended, since (i)

installation of GHEs with spiral pipes is, in general, not as easy

0

20

40

60

80

0

3

6

9

12

15

Heatextraction rate [W/m]

Flow rate [l/min]

Transitional

Laminar

Turbulent

Axial

pitch

Major

diameter

Single

Double cross

Double