3339

Technical Committee 307 + 212 /

Comité technique 307 + 212

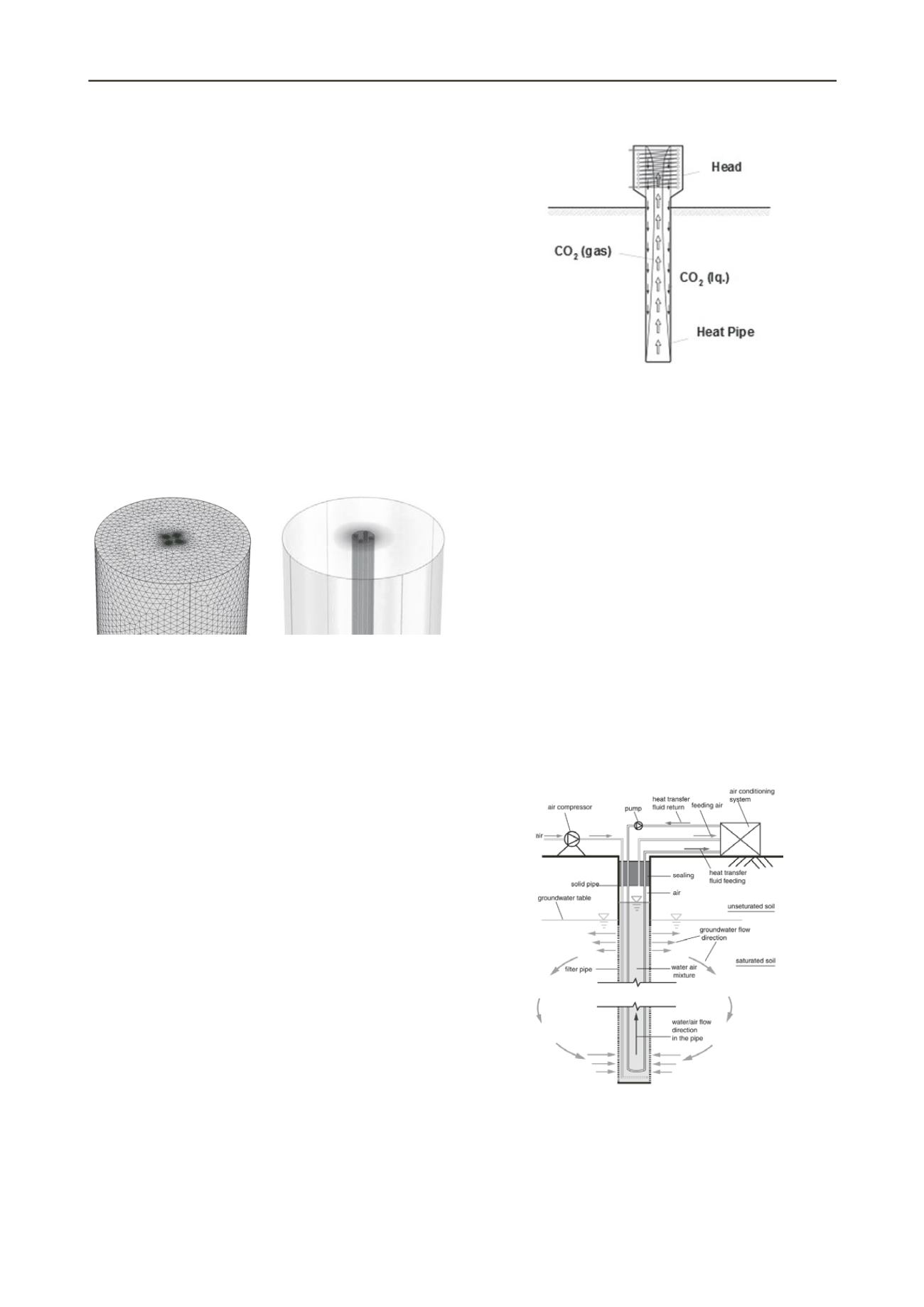

Bidarmaghz et al. studied the effects of different design

parameters such as pipe configuration and fluid flow rate on the

rate of heat extraction, and provided information that may aid

engineers to design an energy-efficient and cost-effective

ground heat exchanger (GHE) system. Finite element analyses

were performed, as shown in Figure 10, to model different pipe-

loop configurations, fluid flow rates and pipe separation, and to

investigate their impacts on the total system efficiency.

Based on the analysis results on a large diameter borehole

and for a given borehole length, Bidarmaghz et al. concluded

that, as long as the same pipe length is embedded inside the

borehole, thermal performance of the system is not significantly

affected by pipe geometry placement. In small diameter ground

heat exchangers (GHEs), the use of double and double cross U-

pipe showed improved performance. The addition of a second

U-pipe to both small and large diameter GHEs achieved

significant additional (40-90%) thermal performance, and this

can lead to major cost savings when compared to single pipe

systems. The analysis also indicated that, when considering the

size of the fluid circulating pump and its operational cost,

highly turbulent fluid flow will not necessarily result in a more

efficient system.

(a)

(b)

Figure 10. Typical finite element model section: (a) mesh of a GHE

with two U-pipes; (b) details of temperature distribution (Figure 2 of

Bidarmaghz et al.).

Katzenbach and Clauss advocated the use of thermosiphon

heat pipes in place of conventional heat exchanger U-pipes in

GHEs because heat pipes eliminate the use of circulation pumps

as the energy is driven through gravity and buoyancy in heat-

pipe borehole heat-exchangers (Figure 11). The thermal

performance of a heat pipe depends on a number of factors like

driving temperature difference, mechanical and thermal

properties (e.g., enthalpy) of the heat-carrying fluid, thermal

conductivity and capacity, energy withdrawal rate on the

condenser side, the geometric dimensions, and the inside

pressure. The authors performed numerical analysis to

investigate the sensitivity of various parameters like the length

and diameter of heat pipe and borehole on the GHE

performance. They found that the relationship between length

and diameter has a large influence on the specific power (heat)

and suggested an optimization of these dimensions in design.

Katzenbach and Clauss concluded that the efficient energy

transport within the heat pipe allows a relative increase in the

coefficient of performance (COP) of 10% or more. They also

collected temperature data from an instrumented geothermal

heat pipe borehole heat exchanger system installed for new,

single-family home. The data was used to compute the expected

heat -power output and to assess the operation efficiency of the

system.

Figure 11. Geothermal heat pipe (Figure 2 of Katzenbach and Clauss).

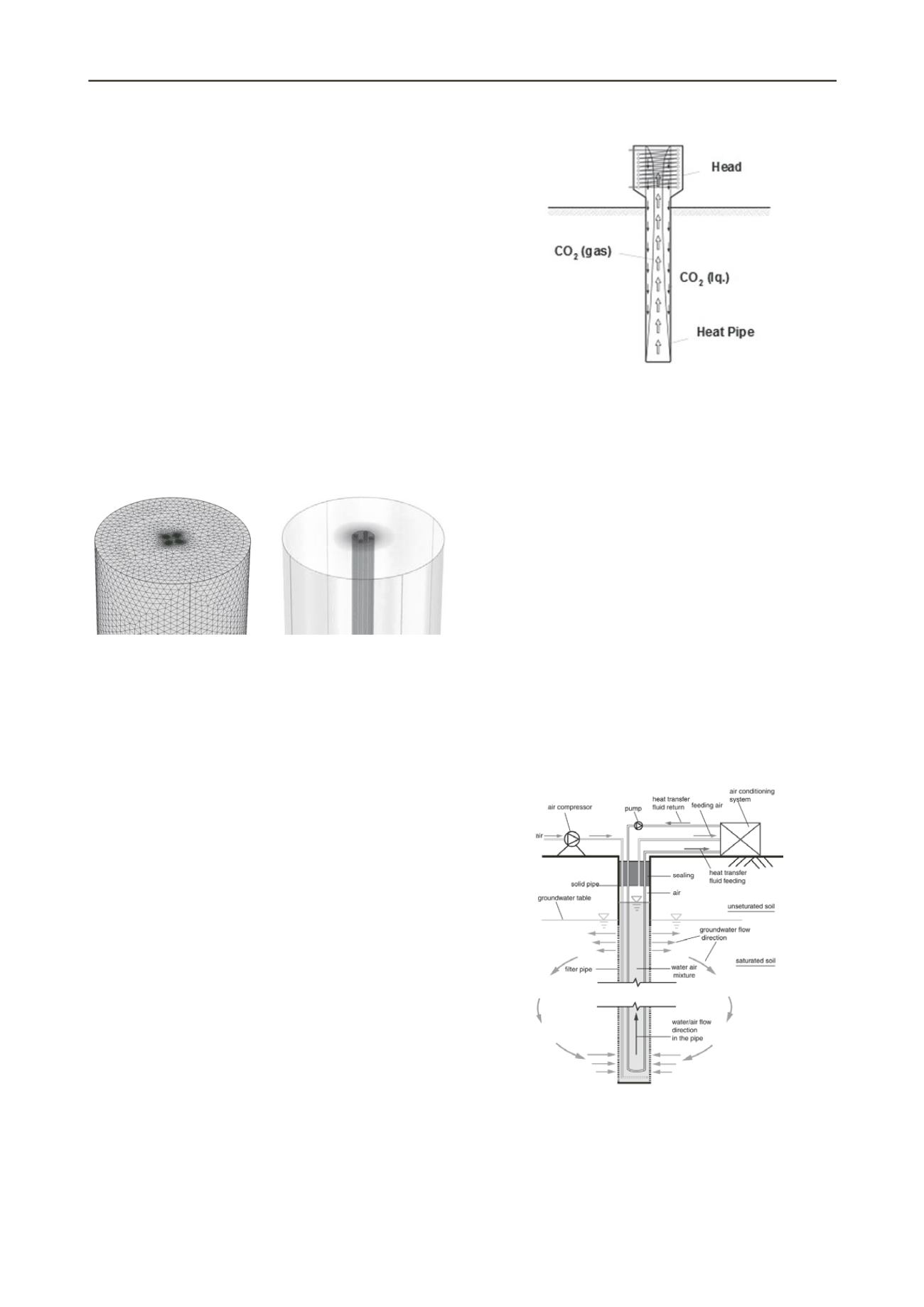

Grabe at al. simulated the performance of a borehole heat

exchanger operated in conjunction with air-sparging induced

groundwater circulation using the multiphysics finite element

software COMSOL. Groundwater circulation around GHE

systems increases the heat-transfer efficiency because heat flow

can then happen through convection in addition to the

conductive flow that occurs in regular closed-loop GHEs. The

authors considered a three-dimensional model in which the heat

exchanger borehole is fitted with heat-exchanger and air-

injection pipes (Figure 12). They neglected flow inside the well

and heat pipes, and considered a homogeneous, sandy aquifer.

The computations were performed by assuming that the

hydraulic and thermal properties of soil are temperature

independent, which implied that groundwater flow is not

influenced by heat transport. Grabe at al. simulated the

groundwater flow till the attainment of stationary conditions.

The results obtained were superimposed with heat propagation

in soil. A parametric study was performed by varying the

density of air-water mixture inside the well, and the thermal and

hydraulic conductivities of soil. A profitability analyses was

also performed based on the numerical results. The authors

concluded that air-sparging well combined with borehole heat

exchanger increased the heat-abstraction capacity and that the

system worked well for soil with high hydraulic conductivity.

Figure 12. Combination of an air-sparging downhole heat exchanger

with an air conditioning system (Figure 1 of Grabe at al.).

Ziegler and Kürten described two examples of novel

geothermal energy utilization technique. In the first example,

the thermal utilization of smouldering mining dump in the Ruhr

area of Germany was described. Three heat-exchange fields

consisting of borehole heat exchangers and temperature gauges

were installed. Several thermal response tests determining the

short-term behavior of the plants and long-term tests were