3331

Technical Committee 210 + 201 /

Comité technique 210 + 201

absolute values and not expressed as a percentage. The average

water content in the peat increases with depth from 6.45 (645%)

to 12.4 (1240%). The organic clay layer shows lower values,

with a large scatter. In the non-organic clay layer the water

content reduces to 0.74 (74%).

A series of CPTs, including measurements with different

cone types and ball penetrometer tests, finalises the subsoil

characterisation. Figure 1 shows a typical CPT for the test field.

In this CPT, the succession of subsoil layers can be recognized.

According to Eurocode ISO/DIS 22476-1:2005,IDT the

measurements represent a class 2 type CPT. For a class 2 CPT

, q

c

, equals 100 kPa. Figure 1

resistance in peat and are therefore used for

co

Simple Shear (DSS)

tes

stress conditions. Since

aches the

su

low, in the order

ents for each

, a ball

ately 0.5

point in the

-

sample

or each

sam

istance

is led

to th

va

cavation, the ditch bottom rose

due to

ining depth during the test

were stepwise filled with

water.

0.25 m increase in water

level.

t step if no failure had

rmation rates slowed

l in the ditch was stepwise

decre

of a 0.25 m lowering of the water

lowering the water table in

instrumentation placed in the second measurement row is

shown. At three depths in the peat layer and at one depth in the

clay layer, the pore pressure development was measured with

Vibrated Wire Probes, VWPs and horizontal displacements

were with a SAA unit, see Abdoun (2007), placed at the front of

the container row. For measurement rows 1 and 2 the pore

pressure development was measured at only two locations in the

peat layer. Besides the instrumentation in the measurement rows

the settlement under the middle two containers was measured

with automated settlement plates, the water level in the

container was measured for each container and the heave of the

ditch after excavation was measurement with settlement plates.

the accuracy of the tip resistance

indicates for the peat a tip resistance of the same order of

magnitude as the accuracy for which the CPT is conducted. This

is typical for peat areas and also reported for other locations

Den Haan & Kruse (2007) and Boylan et al. (2011). The low

accuracy for these measurements makes the conventional class

2 CPT inadequate for accurate correlations with strength

parameters. Ball penetrometer tests give a more accurate

reading of the

rrelation purposes.

occurred in the previous step and defo

3 LABORATORY TESTING

A large series of triaxial tests and Direct

ts were conducted. Discussion of all the test results is beyond

the scope of this paper. This paper focusses on the DSS tests for

which the sample was consolidated at approximately field

stresses. The results of these tests were used to correlate the

undrained shear strength,

s

u,

to ball penetrometer tests according

to equation (2).

(2)

in which

q

ball

represents the penetration resistance of the ball

and

N

ball

represents the resistance factor.

In total 5 samples were tests at field

the density of the peat is low and the water table re

rface the vertical effective stresses are also

of 2 – 7 kN/m

2

. In the set-up of the field measurem

boring, used to retrieve samples for DSS testing

penetrometer test is executed at a distance of approxim

m. The DSS-strength is defined as the deflection

’ diagram, representing the shear stress where the

behaviour changes from compression to dilation. F

ple the DSS-strength is compared to the measured res

in the nearby ball penetrometer test at the same depth. Th

e correlation of

N

ball

= 17.9

1.2.

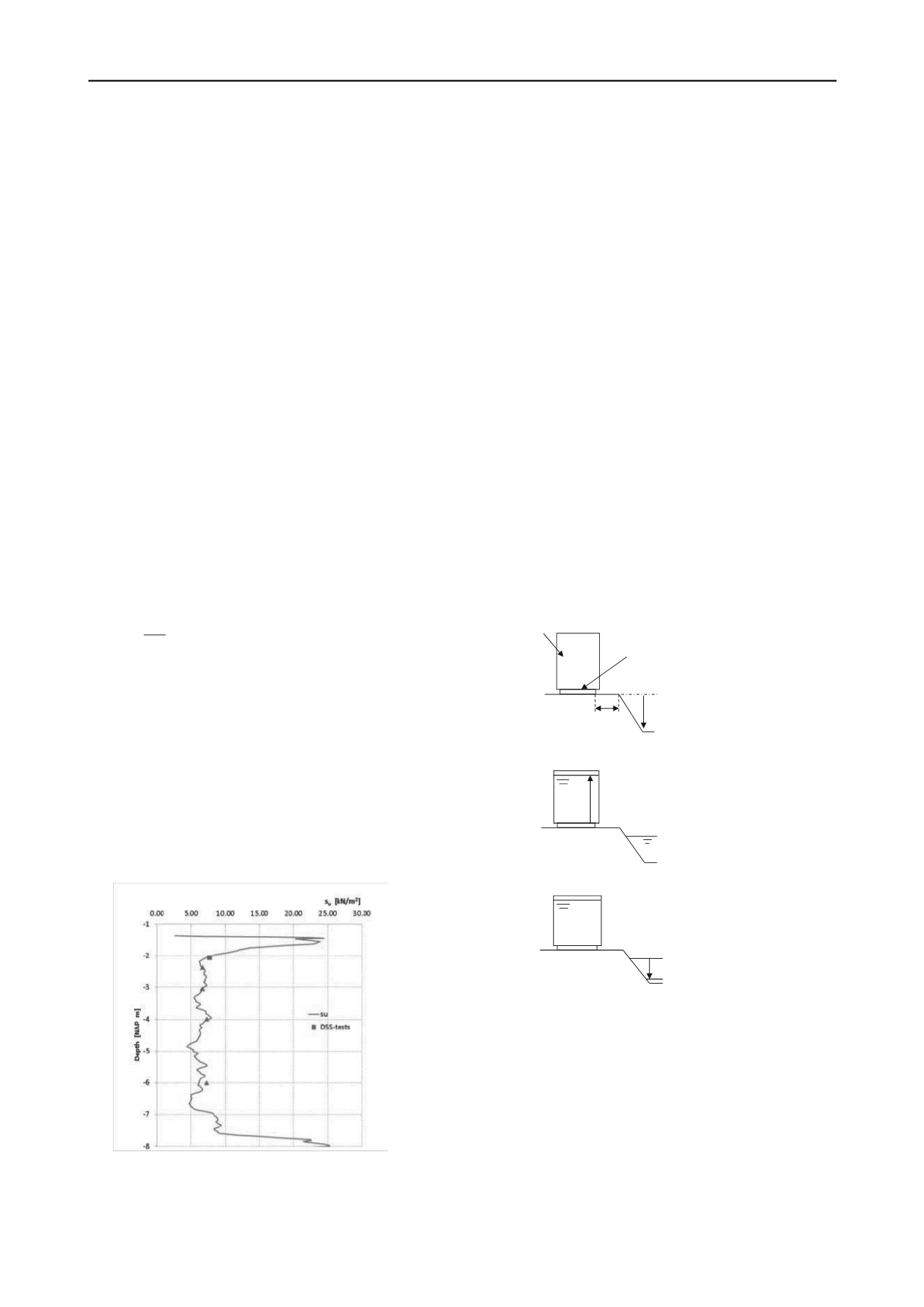

Figure 6. Su from ball penetrometer test S15e and DSS test results.

Red square indicates DSS test at nearby location, red triangles other test

results.

The undrained shear strength from the DSS tests ranges from

6.7 tot 7.7 kN/m

2

with an average value of 7.1 kN/m

2

. The

riation in the test results is small and the average value for

N

ball

found for the individual DSS test results fits well to the

overall strength profile.

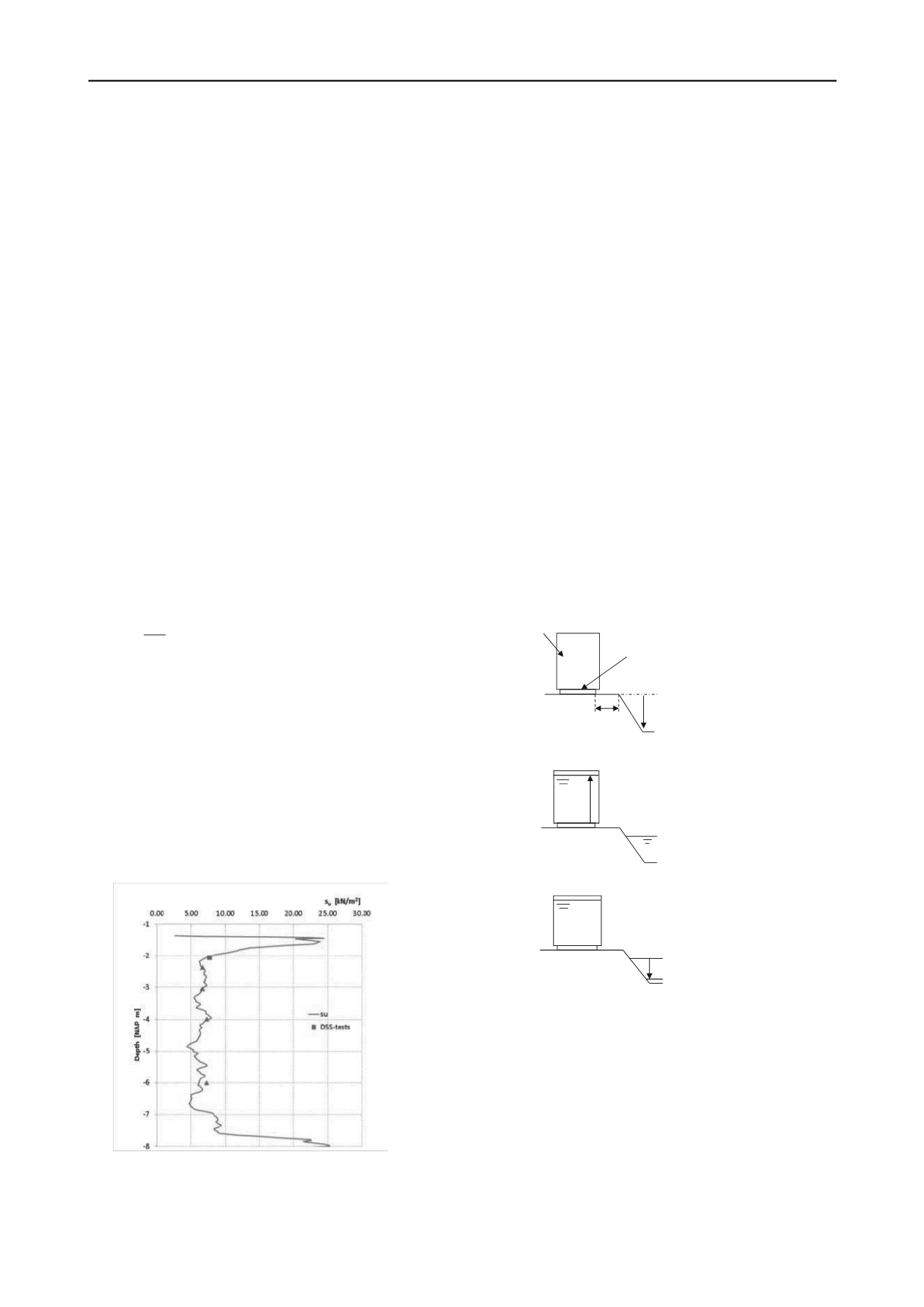

4 TEST SET-UP

In total 5 field tests are conducted. In the first two tests the peat

is loaded in a few days to failure. The other 3 field tests include

a two-periods loading procedure with several weeks of

preloading before failure. This paper focusses only on the first

two tests. For testing reproducibility the test loading is identical.

Figure 7 shows the 3 loading phases of these tests.

In loading phase 1, a row of containers is placed and a ditch

is excavated. The containers have the dimensions of 7.25 m

(length) × 2.5 m (width) × 2.2 m (height). The ditch has a depth

of 2.5 m and slope 1:1. After ex

swelling of the peat. The rema

was approximately 2 m.

In loading phase 2, the containers

Each load step consisted of a

It was decided to start the nex

down significantly.

In loading phase 3, the water leve

ased. Each step consists

table. Failure was found after

loading phase 3.

a) loading phase 1

container

Concrete slab

Figure 7. Planned test set-up

The instrumentation was concentrated in three measurement

rows, see Figure 8. In figure 9 the location of the

ball

u

ball

q s

N

excavation

2.5 m

1 m

b) loading phase 2

c) loading phase 3

were wi

the con

pressur

peat lay

the sett

with a

contain

ditch af

Figure 6. Su from ball penetrometer test S15e and DSS test results.

Red square indicates DSS test at nearby location, red triangles other test

results.

The undrained shear strength from the DSS tests ranges from

6.7 tot 7.7 kN/m

2

with an average value of 7.1 kN/m

2

. The

absolute values and not expressed as a percentage. The average

water content in the peat increases with depth from 6.45 (645%)

to 12.4 (1240%). The organic clay layer shows lower values,

with a large scatter. In the non-organic clay layer the water

content reduces to 0.74 (74%).

A series of CPTs, including measurements with different

cone types and ball penetrometer tests, finalises the subsoil

characterisation. Figure 1 shows a typical CPT for the test field.

In this CPT, the succession of subsoil layers can be recognized.

According to Eurocode ISO/DIS 22476-1:2005,IDT the

measurements represent a class 2 type CPT. For a class 2 CPT

, q

c

, equals 100 kPa. Figure 1

resistance in peat and are therefore used for

co

Simple Shear (DSS)

tes

stress conditions. Since

aches the

su

low, in the order

ents for each

, a ball

ately 0.5

point in the

-

sample

or each

sam

istance

is led

to th

va

cavation, the ditch bottom rose

due to

ining depth during the test

were stepwise filled with

water.

0.25 m increase in water

level.

t step if no failure had

rmation rates slowed

l in the ditch was stepwise

decre

of a 0.25 m lowering of the water

lowering the water table in

instrumentation placed in the second measurement ro is

shown. At three depths in the peat layer and at one depth in the

clay layer, the pore pressure development was measured with

Vibrated Wire Probes, VWPs and horizontal displacements

were with a SAA unit, see Abdoun (2007), placed at the front of

the container row. For measurement rows 1 and 2 the pore

pressure development was measured at only two locations in the

peat layer. Besides the instrumentation in the measurement rows

the settlement under the middle two containers was measured

with automated settlement plates, the water level in the

container was measured for each container and the heave of the

ditch after excavation was measurement with settlement plates.

the accuracy of the tip resistance

indicates for the peat a tip resistance of the same order of

magnitude as the accuracy for which the CPT is conducted. This

is typical for peat areas and also reported for other locations

Den Haan & Kruse (2007) and Boylan et al. (2011). The low

accuracy for these measurements makes the conventional class

2 CPT inadequate for accurate correlations with strength

parameters. Ball penetrometer tests give a more accurate

reading of the

rrelation purposes.

occurred in the previous step and defo

3 LABORATORY TESTING

A large series of triaxial tests and Direct

ts were conducted. Discussion of all the test results is beyond

the scope of this paper. This paper focusses on the DSS tests for

which the sample was consolidated at approximately field

stresses. The results of these tests were used to correlate the

undrained shear strength,

s

u,

to ball penetrometer tests according

to equation (2).

(2)

in which

q

ball

represents the penetration resistance of the ball

and

N

ball

represents the resistance factor.

In total 5 samples were tests at field

the density of the peat is low and the water table re

rface the vertical effective stresses are also

of 2 – 7 kN/m

2

. In the set-up of the field measurem

boring, used to retrieve samples for DSS testing

penetrometer test is executed at a distance of approxim

m. The DSS-strength is defined as the deflection

’ diagram, representing the shear stress where the

behaviour changes from compression to dilation. F

ple the DSS-strength is compared to the measured res

in the nearby ball penetrometer test at the same depth. Th

e correlation of

N

ball

= 17.9

1.2.

Figure 6. Su from ball penetrometer test S15e and DSS test results.

Red square indicates DSS test at nearby location, red triangles other test

results.

The undrained shear strength from the DSS tests ranges from

6.7 tot 7.7 kN/m

2

with an average value of 7.1 kN/m

2

. The

riation in the test results is small and the average value for

N

ball

found for the individual DSS test results fits well to the

overall strength profile.

4 TEST SET-UP

In total 5 field tests are conducted. In the first two tests the peat

is loaded in a few days to failure. The other 3 field tests include

a two-periods loading procedure with several weeks of

preloading before failure. This paper focusses only on the first

two tests. For testing reproducibility the test loading is identical.

Figure 7 shows the 3 loading phases of these tests.

In loading phase 1, a row of containers is placed and a ditch

is excavated. The containers have the dimensions of 7.25 m

(length) × 2.5 m (width) × 2.2 m (height). The ditch has a depth

of 2.5 m and slope 1:1. After ex

swelling of the peat. The rema

was approximately 2 m.

In loading phase 2, the containers

Each load step consisted of a

It was decided to start the nex

down significantly.

In loading phase 3, the water leve

ased. Each step consists

table. Failure was found after

loading phase 3.

a) loading phase 1

container

Concrete slab

Figure 7. Planned test set-up

The instrumentation was concentrated in three measurement

rows, see Figure 8. In figure 9 the location of the

ball

u

ball

q s

N

excavation

2.5 m

1 m

b) loading phase 2

c) loading phase 3