3322

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

dilatants and, consequently, their use represents a significant

risk.In reply to this claim, Perry (1991) says that the highly

erosive nature of the loess is well known. Accordingly, to avoid

the dam core piping formed by silty soil, it requires the

placement of an appropriate filter downstream. Thus Ririe Dam,

built 35 kilometers of Teton Dam, has built a loess core and

designed the appropriate filters, showing satisfactory

performance.

In Argentina, loessial silts have been used in several dams

and roadworks. The most important example is the Rio Hondo

Dam, built in the 1960s, regardless dispersion problems (Grandi

et al, 1961). The material used in this work is a silt with a clay

content between 15 and 20% and plasticity index of 6%

(Moretto et al, 1963). In structural revisions made several

decades after its construction, it was concluded that the dam has

adequate hydraulic behavior. Buraschi and Pujol (1999) have

discussed the possibility of internal erosion in this dam.

This paper discusses the hydraulic stability sandy silt soil

type, in the compacted state. The material is subjected to

erosion situations under the application of several hydraulic

gradients. For the protection of silt, it has been used natural

filters with different particle sizes. One of the most discussed

issues at the international level is the testing methodology. The

authors have optimized an analysis methodology based on the

use of a filter cell. The results of the test campaign performed

with the technique developed by the authors of this publication

are presented.

2 COMPOSITION OF THE STUDY

2.1 Soil involved in testing

The characteristics of the soil tested in these studies have

been described by different authors, Reginatto (1970), Moll and

Rocca (1991). Loessial soils of central Argentina are formed

mainly by silt. The grain size composition comprising: sand

(2% to 10%), silt (40% to 80%), and clay (20% to 35%). The

composition is completed by calcium carbonate, variable

between 2% and 10%, which exists in the form of nodules,

called “toscas”, or precipitate in the contact between particles.

These soils are alkaline, with pH> 8.

The physical properties of the soil tested are shown in Table 1.

Table 1.Properties of base material used

Property

Value

Natural moisture (ω), (%)

12.7 - 20.7

Dry Unit Weight (

d

), (kN/m

3

)

12.3

Specific Gravity (Gs)

2.65

Liquid Limit (ω

l

), (%)

24.4

Plastic Limit (ω

p

), (%)

21.0

Plastic Index (PI), (%)

3.4

Particles< 4.50 mm, (%)

100.0

Fines < 0.075 mm, (%)

93.4

Clay< 0.002 mm, (%)

14.0

USCS Classification

ML

Through compaction tests yielded a value of 15.5% optimum

moisture and maximum dry unit weight of 17.6 kN/m

3

. To

simulate conditions of poor compaction, tests were conducted

with the application of 90% of the energy corresponding to

Standard Proctor test.

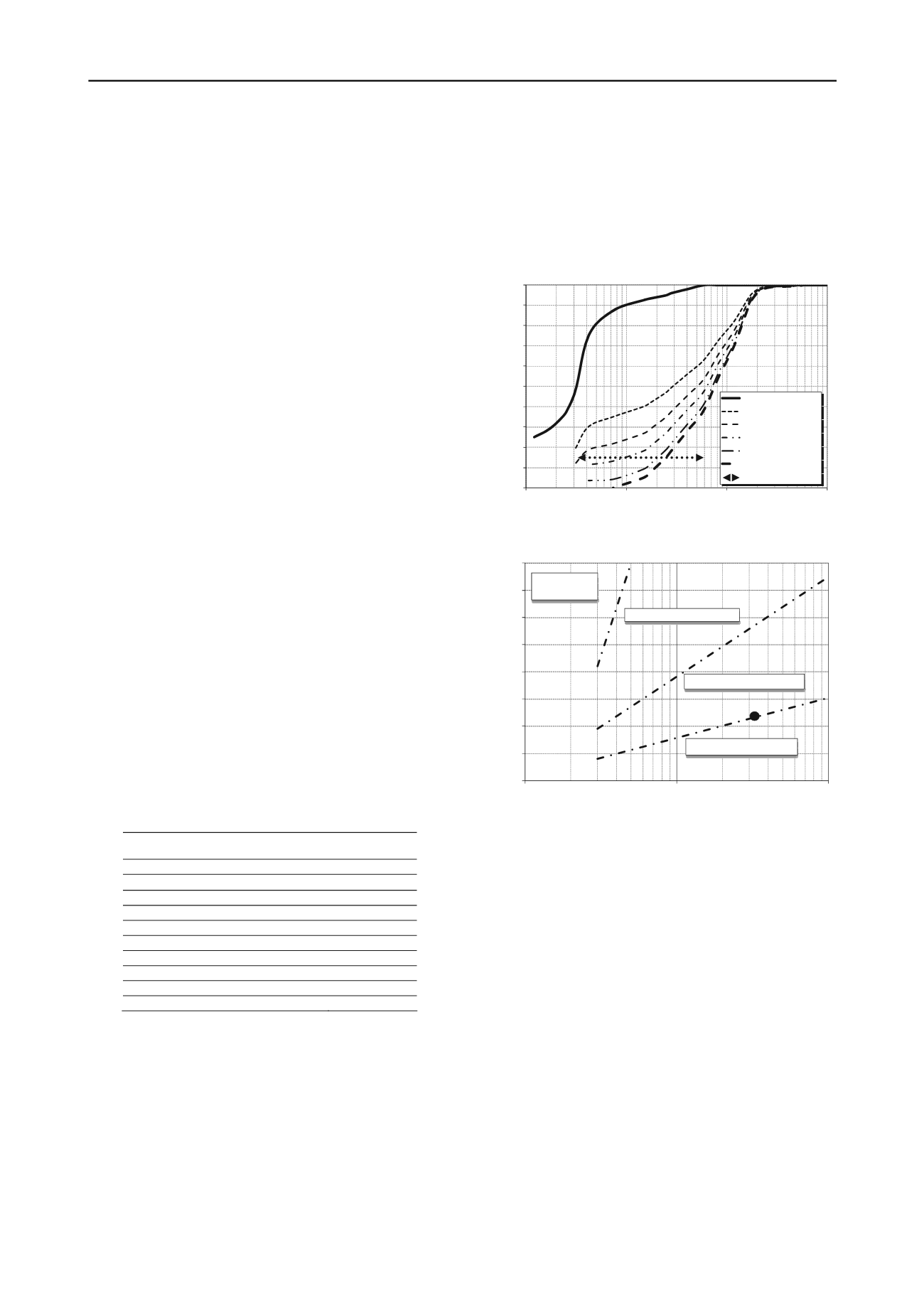

Fine grain sand was used as a base material for the

construction of the filter. This type has been called SP, as the

unified system. Zeballos et al (2010) have shown the unstable

behavior of the system formed by compacted loess and filter,

when it is formed only by sand. In the results presented in this

paper, using filters formed by a combination of sand and silt

loess, the filtration was measured. It has also been analyzing the

operation of the set soil - filter, both under transient and steady

flow. The mixtures tested as filters, have used combinations of

sand and silt with a share of sand: 60%, 75%, 85% and 95%,

relative to the total weight. The mixtures formed are presented

in Figure 1. In the same Figure, the range corresponding to 15%

pass filter (d

15f

%) frequently recommended, is presented. Each

of these mixtures was tested with the application of hydraulic

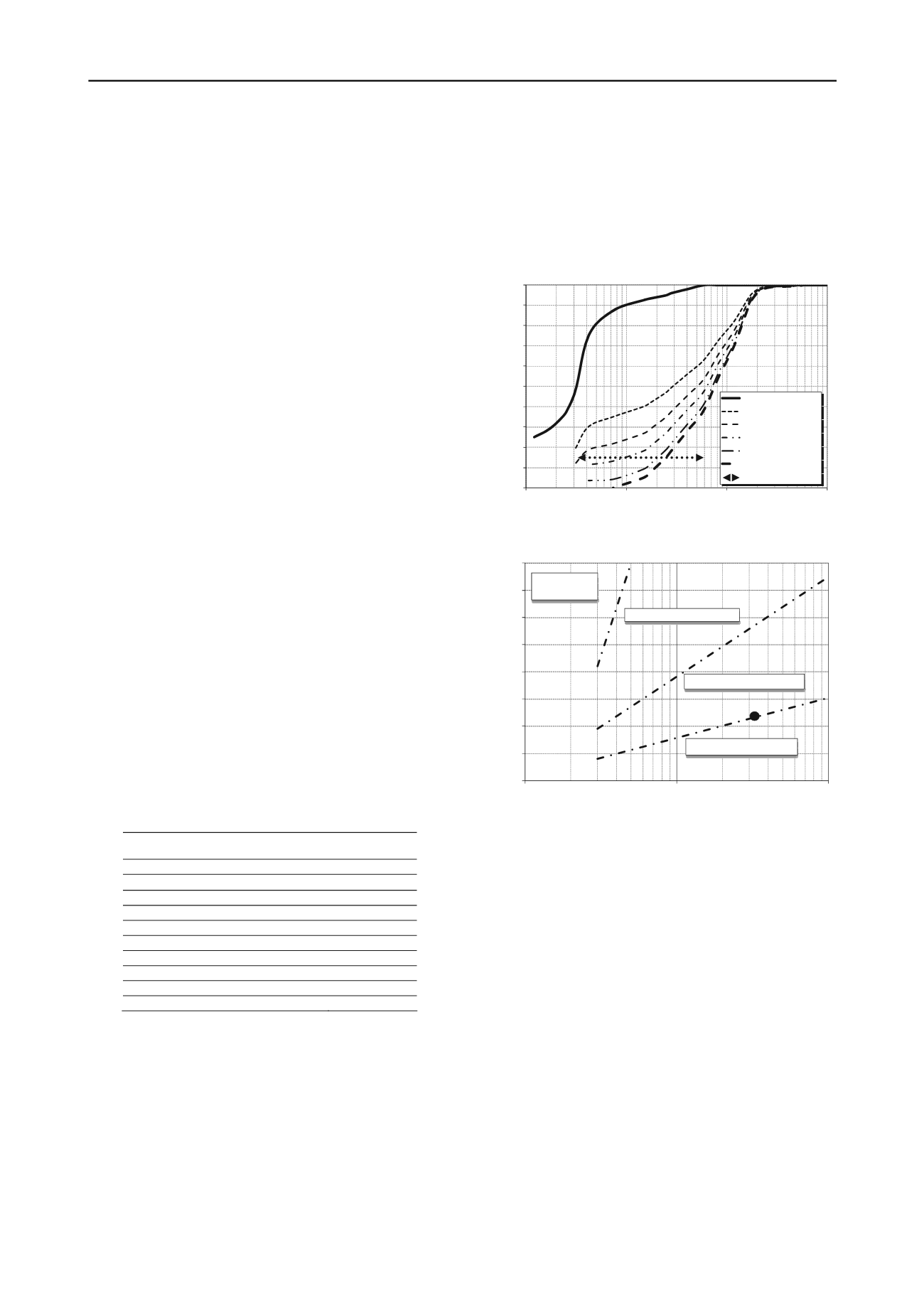

gradients in the order of 20, 40 and 80. Figure 2 shows the

location of the soil analyzed according to the classification of

Burenkova (1993).

0

10

20

30

40

50

60

70

80

90

100

0.01

0.1

1

10

Passing Porcentage [%]

Grain Dimensions [mm]

Silt

60%sand - 40% silt

75%sand - 25% silt

85%sand - 15% silt

95%sand - 5% silt

Sand

Recommended range

Figure 1.Particle size of the soils used in the study.

Base Soil

SILT

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

1

10

100

d90 / d60

d90 / d15

I - Suffusion Zone

II - NO Suffusion Zone

III - Suffusion Zone

IV - Artificial

Soils

Figure 2.Burenkova chart for characterizing the potential of suffusion.

Location of the studied silts

.

For the materials used in this study, it is possible to make the

following comments:

Burenkova graph, locates the soil base tested (loess silt), in

the limit of the erosive behavior.

Several filter mixtures tested has fines content greater than

that normally recommended for the treatment of these

problems, (not exceeding 5% of passing sieve 200).

2.2 Tests Performed

A filtration chamber of large dimensions has been designed.

The cylindrical chamber has a height of 500 mm with a span of

105 mm diameter. The chamber was constructed with

transparent plastic, which allows visual monitoring of the

filtration process. At its top, the chamber is connected with the

water injection system pressure. In its lower part is connected to

the flow registration system and containment system of solid

particles. The chamber used, in schematic form, is presented in

Figure 3.

In the upper part of the chamber is placed a granular material

(drain) to facilitate the distribution of incoming water to the

beaker. This allows the water to reach the probe evenly. The

soil tested is located below the drain. The height of the cylinder

is regulated depending on the applied hydraulic gradient. The