3323

Technical Committee 210 + 201 /

Comité technique 210 + 201

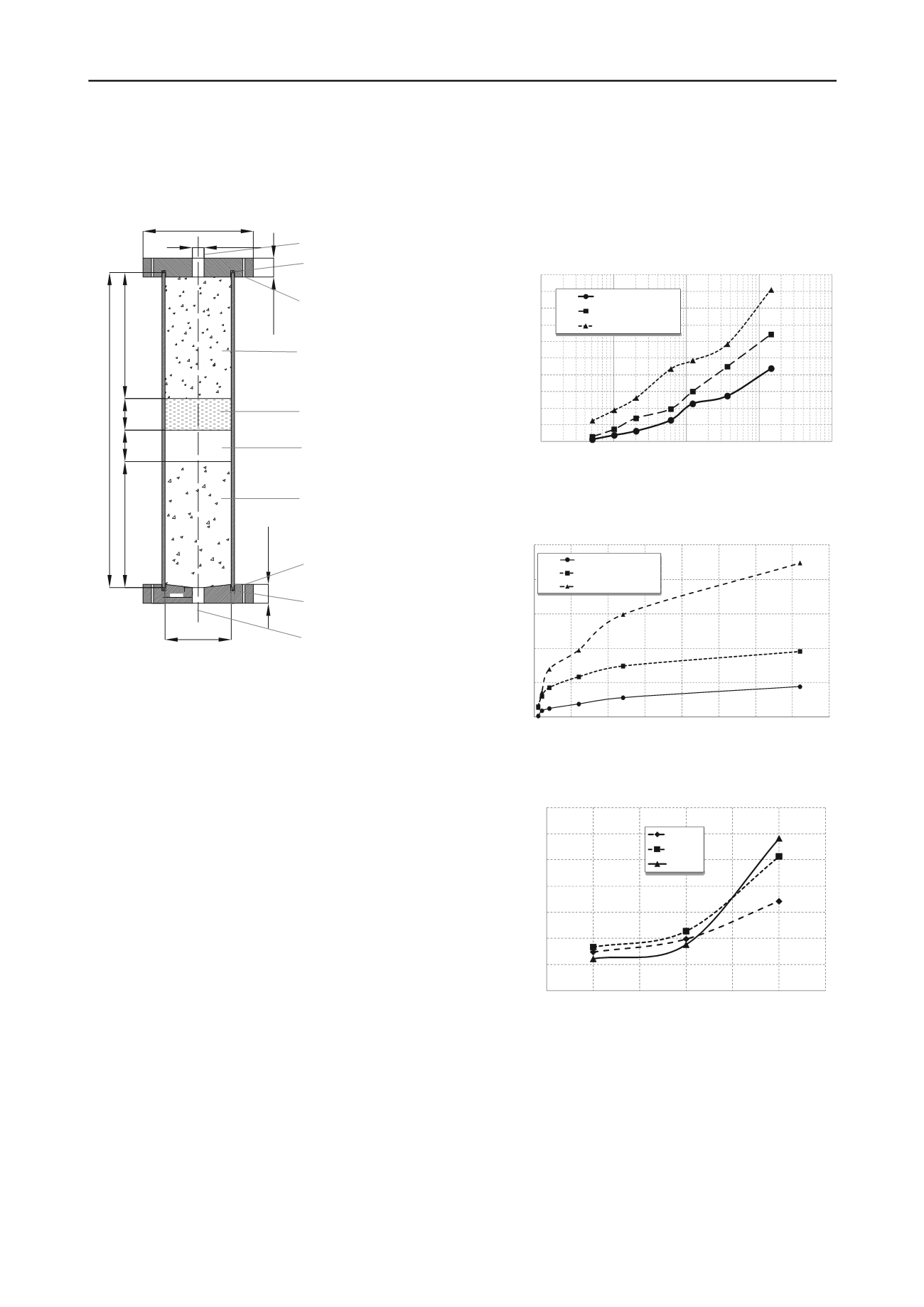

filter is located below the probe, and then places another drain.

The test apparatus has a bottom plate with an outlet hole that

allows fluid control, and the collection of solid particles which

migrate from the soil or filter.

43,1mm

105 mm

500 mm

200 mm

50 mm 50 mm

200 mm

Orificio para Ingreso

Fluido y Control de Presión

O-Ring de goma - Sellador

175 mm

ESPACIO DE DISTRIBUCION

DE FLUIDO Y EQUILIBRIO DE

PRESIONES

(Material Dren)

SUELO BASE

FILTRO

ESPACIO DE DRENAJE INFERIOR

(Material Dren)

19 mm

O-Ring de goma - Sellador

30 mm

Orificio para Egreso de

Fluido y Recolección

30 mm

Orificio de vinculo entre cabezales

Orificio de vinculo entre cabezales

Hole for water ingress and

pressure control

Membranetype

O‐ring tire

Spindle‐hole adjustment

SAMPLE

Filter

Spindle‐hole adjustment

Membranetype

O‐ring tire

Exit hole wat r and solids

collection

SPACE BOTTOM

DRAIN

S ACE DISTRIBUTION F

FLUID

SPACE FOR APPLICATIONOF

PRESSURE

Figure 3. a) Schematic of the test system.

Prior to the execution of tests, a hole is drilled in the central

part of the specimen to simulate a crack from uncontrolled

erosion which could be initiated, or be achieved the overall

instability of the material.

In the preparation of the test system, some difficulties have

occurred in the installation of the filter and drain. An internal

protocol was developed to avoid the complications caused by

the lack of good contact between the various layers of the

filtration column.

Tests have been carried out, in all cases, starting the process

from the moisture condition of compaction. The filtered water

volume and the weight of the solids passing through the

filtration system were measured in all trials. In all cases,

measurements were performed at intervals of time. Tests have

lasted more than one day, until a leak was observed in steady

state condition.

3 RESULTS

The variables in the set of tests were as follows: a) volume of

water filtered vs. time, b) amount of filtered solids through the

system, c) filtration rate, when the process is in steady state, d)

steady state permeation.

Within the set of tests, the results for the filters with 60% of

sand are not included in this paper. These filters have shown a

highly unstable behavior, with great loss of material during

filtration.

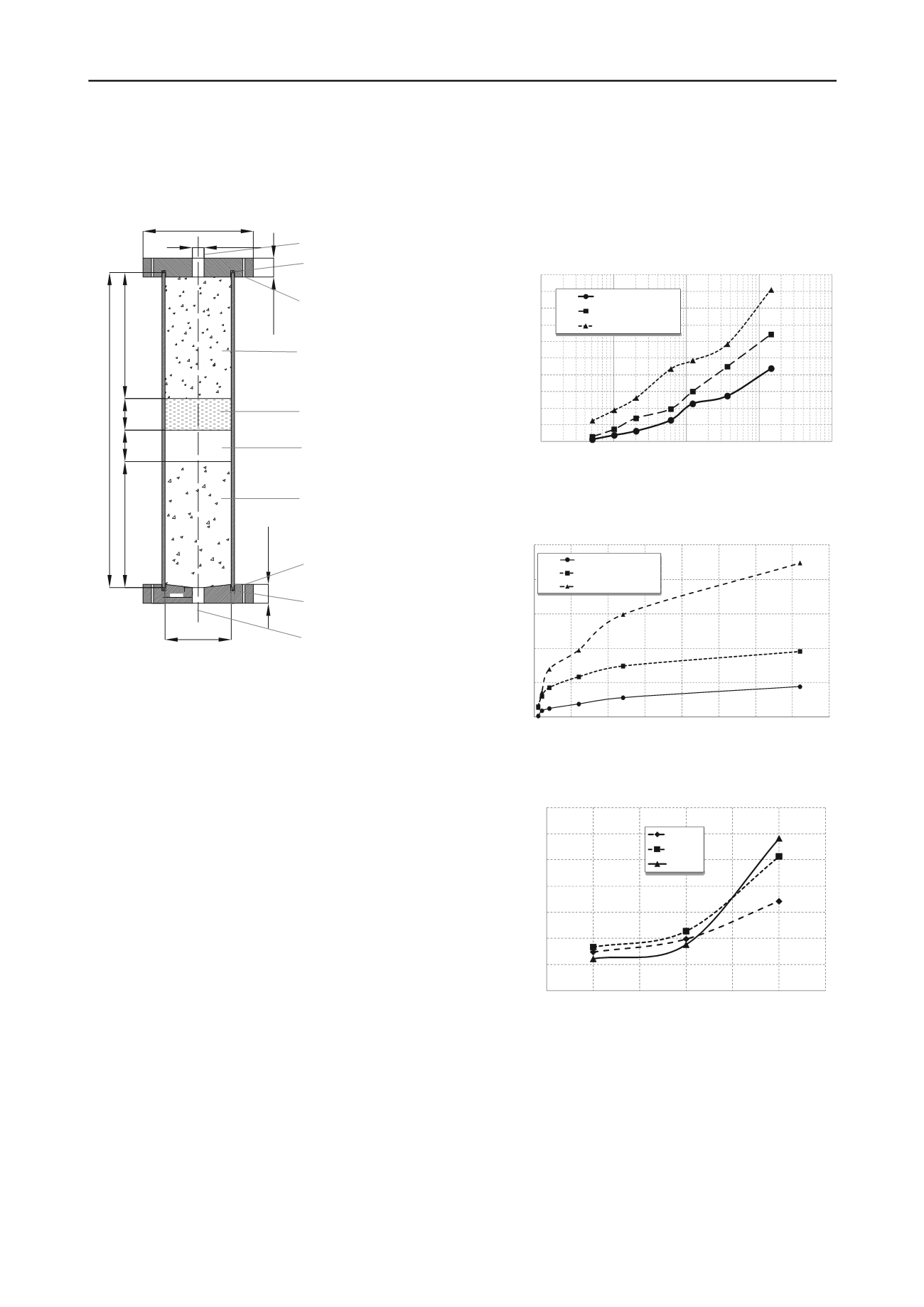

Figures 4a and 4b, for example, show the variation in the

volume of filtered water to the various mixtures made and

applied gradients. There is a growing trend for leaks with the

gradient applied. The same trend was observed with the sand

content in the filter.

In relation to the migration of particles, Figure 5 shows the

percentage of solids that migrate with respect to the initial dry

weight of the sample. The solids lost during the test tend to

increase proportionally to the content of sand in the mixture.

The losses are moderate for the filters having no more than 85%

sand. For filters with 95% sand, the loss rate increases to more

than double, compared to the previous cases. Much of the

migration of solids occurs in the first minutes of the test. After

the initial stage there is clear water seepage through the system.

Figure 4.a. Changes in the volume of filtered water, as represented in

logarithmic scale.

0

500

1000

1500

2000

2500

3000

3500

4000

4500

5000

1

10

100

1000

10000

Volume of water passing through the

specimen (cm

3

)

Time (min)

Grad80 ‐ 75%Sand

Grad80 ‐ 85%Sand

Grad80 ‐ 95%Sand

0

500

1000

1500

2000

2500

0

50

100

150

200

250

300

350

400

Volume of water passing through the

specimen (cm

3

)

Time (min)

Grad20 ‐ 85%Sand

Grad40 ‐ 85%Sand

Grad80 ‐ 85%Sand

Figure 4.b. Representation of the evolution of the volume filtered,

represented in full scale

0.00

0.05

0.10

0.15

0.20

0.25

0.30

0.35

70% 75% 80% 85% 90% 95% 100%

% Solids with respect to the dry weight

of soil sample

% of sand in filter

Grad 20

Grad40

Grad80

Figure 5.Solids losses during the test.

The filtration system tested shows a leak with the

characteristics of a regular stationary regime after an initial

transient stage.

The stability of the system can be seen through the

identification of the mean values of permeability. These values

are constant, even for different values of gradients.

The results, measured as rate of leak flux in the stationary

phase and the permeability at this stage are shown in Table 2.

filter is located below the probe, and then places another drain.

The test apparatus has a bottom plate with an outlet hole that

allows fluid control, and the collection of solid particles which

migrate from the soil or filter.

43,1mm

105 mm

500 mm

200 mm

50 mm 50 mm

200 mm

Orificio para Ingreso

Fluido y Control de Presión

O-Ring de goma - Sellador

175 mm

ESPACIO DE DISTRIBUCION

DE FLUIDO Y EQUILIBRIO DE

PRE IONES

(Material Dren)

SUELO BASE

FILTRO

ESPACIO DE DRENAJE INFERIOR

(Material Dren)

19 mm

O-Ring de goma - Sellador

30 mm

Orifi io para Egreso de

Fluido y Recolección

30 mm

Orificio de vinculo entre cabezales

Orificio de vinculo entre cabezales

Hole for water ingress and

pressure control

Membranetype

O‐ring tire

Spindle‐hole adjustment

SAMPLE

Filter

Spindle‐hole adjustment

Membranetype

O‐ring tire

Exit hole water a d solids

collectio

SPACE BOTTOM

DRAIN

PACE DISTRIBUTION F

FLUID

SPACE FOR APPLICATIONOF

PRESSURE

Figur 3. a) Schematic of the test system.

Prior to the execution of tests, a hole is drilled in the central

part of the specimen to simulate a crack from uncontrolled

erosion which could be initiated, or be achieved the overall

instability of the material.

In the preparation of the test system, some difficulties have

occurred in the installation of the filter and drain. An internal

protocol w s developed to avoid the complications caused by

the lack of good contact between the various layers of t

filtration column.

Tests h ve been carried out, in all cases, starting the process

from the moisture c ndition of compaction. The filtered water

volume and the weight of the solids passing t rough the

filtration system were measured in all trials. In all cases,

measurements were performed at intervals of time. Tests have

lasted more than one day, until a leak was observed in steady

state condition.

3 RESULTS

The variables in the set of tests were as follows: a) volume of

water filtered vs. time, b) amount of filtered solids through the

system, c) filtration rate, when the process is in steady state, d)

steady state permeation.

Within the set of tests, the results for the filters with 60% of

weight of the sample. The solids lost during the test tend to

increase proportionally to the content of sand in the mixture.

The losses are moderate for the filters having no more than 85%

sand. For filters with 95% sand, the loss rate increases to more

than double, compared to the previous cases. Much of the

migration of solids occurs in the first minutes of the test. After

the initial stage there is clear water seepage through the system.

Figure 4.a. Changes in the volume of filtered water, as represented in

logarithmic scale.

0

500

1000

1500

2000

2500

3000

3500

4000

4500

5000

1

10

100

1000

10000

Volume of water passing through the

specimen (cm

3

)

Time (min)

Grad80 ‐ 75%Sand

Grad80 ‐ 85%Sand

Grad80 ‐ 95%Sand

0

500

1000

1500

2000

2500

0

50

100

150

200

250

300

350

400

Volume of water passing through the

specimen (cm

3

)

Time (min)

Grad20 ‐ 85%Sand

Grad40 ‐ 85%Sand

Grad80 ‐ 85%Sand

Figure 4.b. Representation of the evolution of the volume filtered,

represented in full scale

0.00

0.05

0.10

0.15

0.20

0.25

0.30

0.35

70% 75% 80% 85% 90% 95% 100%

% Solids with respect to the dry weight

of soil sample

% of sand in filter

Grad 20

Grad40

Grad80

Figure 5.Solids losses during the test.

The filtration system tested shows a leak with the

filter is located below the probe, and then places another drain.

The test apparatus has a bottom plate with an outlet hole that

allows fluid control, and the collection of solid particles which

migrate from the soil or filter.

43,1mm

105 mm

500 mm

200 mm

50 mm 50 mm

200 mm

Orificio para Ingreso

Fluido y Control de Presión

O-Ring de goma - Sellador

175 mm

ESPACIO DE DISTRIBUCION

DE FLUIDO Y EQUILIBRIO DE

PRESIONES

(Material Dren)

SUELO BASE

FILTRO

ESPACIO DE DRENAJE INFERIOR

(Material Dren)

19 mm

O-Ring de goma - Sellador

30 mm

Orificio para Egreso de

Fluido y Recolección

30 mm

Orificio de vinculo entre cabezales

Orificio de vinculo entre cabezales

Hole for water ingress and

pressure control

Membranetype

O‐ring tire

Spindle‐hol adjustment

SAMPLE

Filter

Spindle‐hole adjustment

Membranetyp

O‐ring tire

Exit hole wat r and solids

collection

SPACE BOTTOM

DRAIN

S A E DISTRIBUTION F

FLUID

SPACE FOR APPLICATIONOF

PRESSURE

Figure 3. a) Schematic of the test system.

Prior to the execution of tests, a hole is drilled in the central

part of the specimen to simulate a crack from uncontrolled

erosion whic could be initiated, or be achieved the overall

instability of th material.

In the preparation of the test system, some difficulties have

occurred in the installation of the filter and drain. An internal

protocol was devel ped to avoid the complications caused by

the lack of good contact betwe n the various lay rs of the

filtrati n column.

Tests have been carried out, in all cases, starting the process

from the moisture condition of compaction. The filtered water

volume and th weight of the solids pa sing through the

iltration system were measured in all trials. In all cases,

measurements were perfor ed at intervals of time. Tests hav

lasted more than on day, until a leak was ob erved in steady

state condition.

3 RESULTS

The variables in the set of tests were as follows: a) volume of

water filtered vs. time, b) amount of filtered solids through the

system, c) filtration rate, when th process is in steady state, d)

steady state permeation.

Within the set of tests, the results for the filters with 60% of

sand are not included in this paper. These filters have shown a

highly u stable behavior, with great loss of material during

filtration.

Figures 4a and 4b, for example, show the variation in the

volume of filtered water to the various mixtures made and

applied gradients. There is a growing trend for leaks with th

gradient applied. The same trend was observed with the s

content in the filter.

In relation to the migration of particles, Figure 5 shows the

perc tage of solids that migrate with respect to the initial dry

weight of the sample. The solids lost during the test tend to

increase proportionally to the content of sand in the mixture.

The losses ar moderate for the filters having no mor than 85%

sand. For filters with 95% sand, the loss rate increas s to more

than double, compared to the previous cases. Muc of the

migrati n of solids occurs in the first minut s of the test. After

t e initial stage there is clear water seepage through the system.

Figure 4.a. Changes in the volume of filt red wate , as repr sented in

logarithmic scale.

0

1

1

2

2

3 0

3

4000

4500

5000

1

10

100

1000

10000

Volume of water passing through the

specimen (cm

3

)

Time (min)

Grad80 ‐ 75%Sand

Grad80 ‐ 85%Sand

Grad80 ‐ 95%Sand

5

0

15

0

2500

0

50

100

150

200

250

300

350

400

Volume of water passing through the

specimen (cm

3

)

Time (min)

Grad20 ‐ 85%Sand

Grad40 ‐ 85%Sand

Grad80 ‐ 85%Sand

Figure 4.b. Representation of the evolution of the volume filtered,

represented in full scale

0.00

0.05

0.10

0.15

0.20

0.25

0.30

0.35

70% 75% 80% 85% 90% 95% 100%

% Solids with respect to the dry weight

of soil sample

% of sand in filter

Grad 20

Grad40

Grad80

Figure 5.Solids losses during the test.

The filtration system tested shows a leak with the

characteristics of a regular stationary regime after an initial

transient stage.

The stability of the sy tem can be s en through the

ide tification of the mean values of permeability. These values

are constant, even f r different values of gradients.

The results, m asured as rate of leak flux in the tationary

phase and the p rmeability at this stage are shown in Table 2.