3332

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

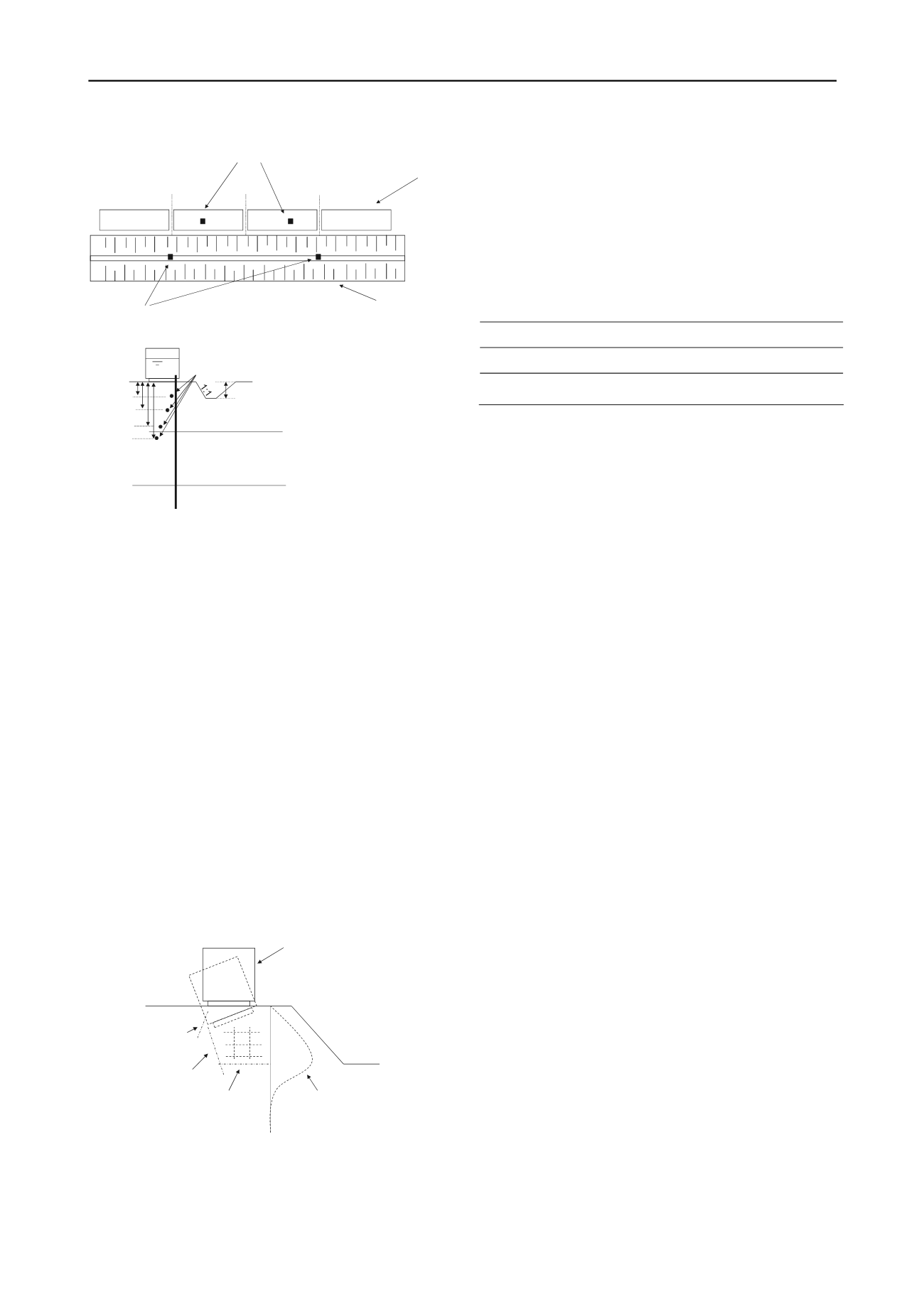

Figure 8. Top view

Figure 9. Instrumented cross section, VWP = vibrated wire probe.

5 RESULTS

The tests were run in approximately three days and this loading

scheme resembles the loading velocity for river dikes, where

high water levels rise and decline in a matter of days.

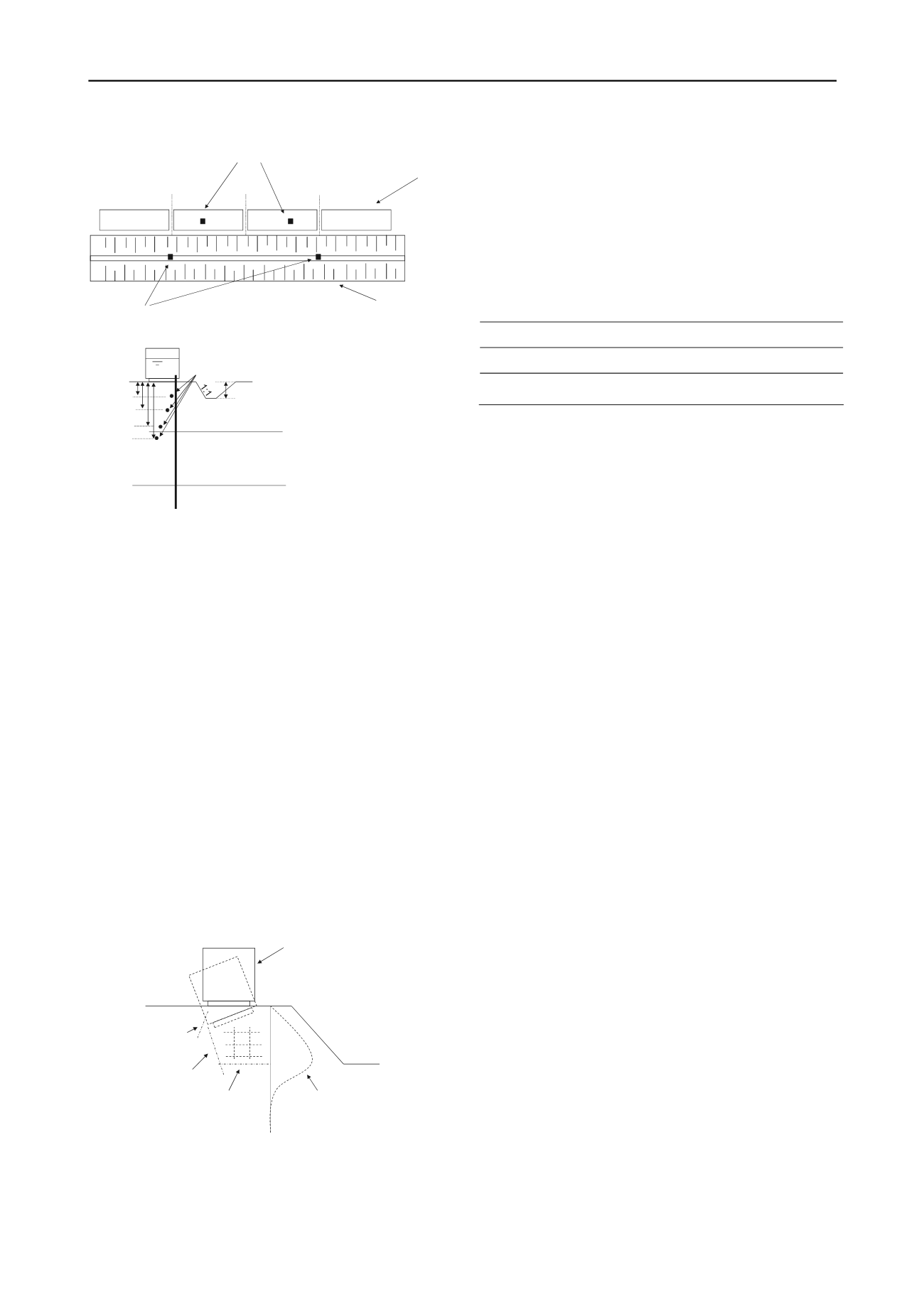

After the test was finished an excavation pit was made to

study subsoil cracks and failure planes. These observations

resulted in a reconstruction of the failure mechanism as shown

in Figure 10 At the active side a clear and nearly vertical rupture

plane was found accompanied with a secondary, backward

running crack. This rupture plane intersected a nearly horizontal

rupture plane. The horizontal rupture plane is only found at the

at

er row, is

e was found at the

act

the ditch was

at the horizontal

dis

ers were

e

ne a series

ound. It is not

the test, when

to the

dimensions of the field tests are limited, 3D effects play

Bas

imensions of the failure plan s estimated

the friction along the sides of the failure mechanism adds

app

y 10% extra friction to a plane strain assu

failure plane. So, failure is to be found for a calculated Safety

r the analysis the Spencer and LiftVan

he LiftVan method, Van et al (2005), is

a B

active side of the failure. The maximum displacement found

the end of the test, measured at the front of the contain

found at the same depth as the rupture plan

ive side. At the end of the test the slope of

nearly unaffected. This led to the conclusion th

placements, measured at the front of the contain

followed by horizontal compaction of the peat between th

containers and ditch.

Between the containers and horizontal rupture pla

of minor horizontal and vertical cracks were f

known whether these cracks were formed during

the peat layer was loaded or after during swelling due

removal of the load.

Figure 10. Sketch of failure mechanism.

6 ANALYSIS

After finalizing the field tests, an extended analysis was

conducted including limit equilibrium analysis. Since the

a role.

ed on the d

es it i

that

roximatel

med

automated settlement plates

Factor, SF = 0.9. Fo

method were applied. T

ishop based method and includes a horizontal sliding plane

between the active and passive parts of the slip circle with

different radii. Back analysis with the conditions at which

failure was found led to the average undrained shear strength,

s

u,

available at failure. Table 1 shows the results.

Table 1. Back analysis of test results,

s

u

in [kN/m

2

] for which SF = 0.9.

Model

Test 1

Test 2

LiftVan

7.0

7.8

Spencer

7.3

8.0

7 CONCLUSIONS

The large scale field tests on the peat subsoil were conducted

successfully. Measurements show an equivalent development of

deformations and pore pressure in both tests. Together with the

small differences found in the back analysis this indicates a

go reproducibility of these tests.

The strength found in the D

od

SS lab tests, in which the

hows that the

istance during the test is in the range

esponds well to the strength found

for

The

9

Abd

007 Field

Boylan N., Long M., Mathijssen F.A.J.M. 2011 In situ strength

characterisation of peat and organic soil using full flow

penetrometers

Can Geotech J.

48

:1085-1099

Den Haan E.J. (2007) De intrinsieke tijd in het isotachenmodel

Geotechniek

12

(1), 34-38 (in Dutch)

Den Haan, E.J. & Kruse, G.A.M. (2007) Characterisation and

engineering properties of Dutch peats In:

Second international

workshop on characterisation and engineering of natural soils

Singapore

vol. 3 London Taylor & Francis p 2101 -2133

Skempton A.W., Petley D.J. 1970. Ignition loss and other properties of

peats and clays from Avonmouth, Kings Lynn and Cranberry Moss,

Géotechnique

20

(4), 343-356.

Van M.A., Koelewijn A.R., Barends F.B.J. 2005 Uplift phenomenon :

Model, Validation and Design

international Journal of

Geomechanics

5:2, 98-106.

samples are consolidated at field stress level, correlate well to

ball penetrometer tests. This resulted in a correlation between

the ball cone field test and the DSS lab test.

he back analysis of the container tests s

T

average available shear res

of 7 to 8 kN/m

2

. This corr

from the DSS tests.

The combination of ball penetrometer tests and DSS tests,

which the sample is consolidated at field stress level,

vide a valuab

pro

le tool in obtaining peat strength parameters for

safety assessments of dikes on peaty subsoil.

8 ACKNOWLEDGEMENTS

research project, including the field tests, is initiated and

funded by Hoogheemraadschap Hollands Noorderkwartier in

cooperation with Rijkswaterstaat – Waterdienst.

REFERENCES

oun T., Bennet V., DanischL., Shantz T. & Jang D. 2

Installation details of a wire-less shape-acceleretion array system

for geotechnical applications

Proceedings of SPIE, San Diego

volume 6529

Becker D.E., Crooks J.H.A., Been K., Jefferies M.G. 1987 Work as a

criterion for determining in situ and yield stresse in clays

Can.

Geot. J

24

:549-564

1

row 1

container row

row 2

row 3

2

3

4

excavation

settlement plate

clay

peat

2.5 m

VWP

4,6 m

SAA

1,6 m

3,1 m

sand

5,6 m

measured horizontal

displacements

horizontal fracture and

several minor vertical cracks

main vertical fracture

secondary vertical

fracture

tilted container