3340

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

carried out. Numerical simulations and analytical investigations

were also performed to identify the important parameters that

influence the heat output.

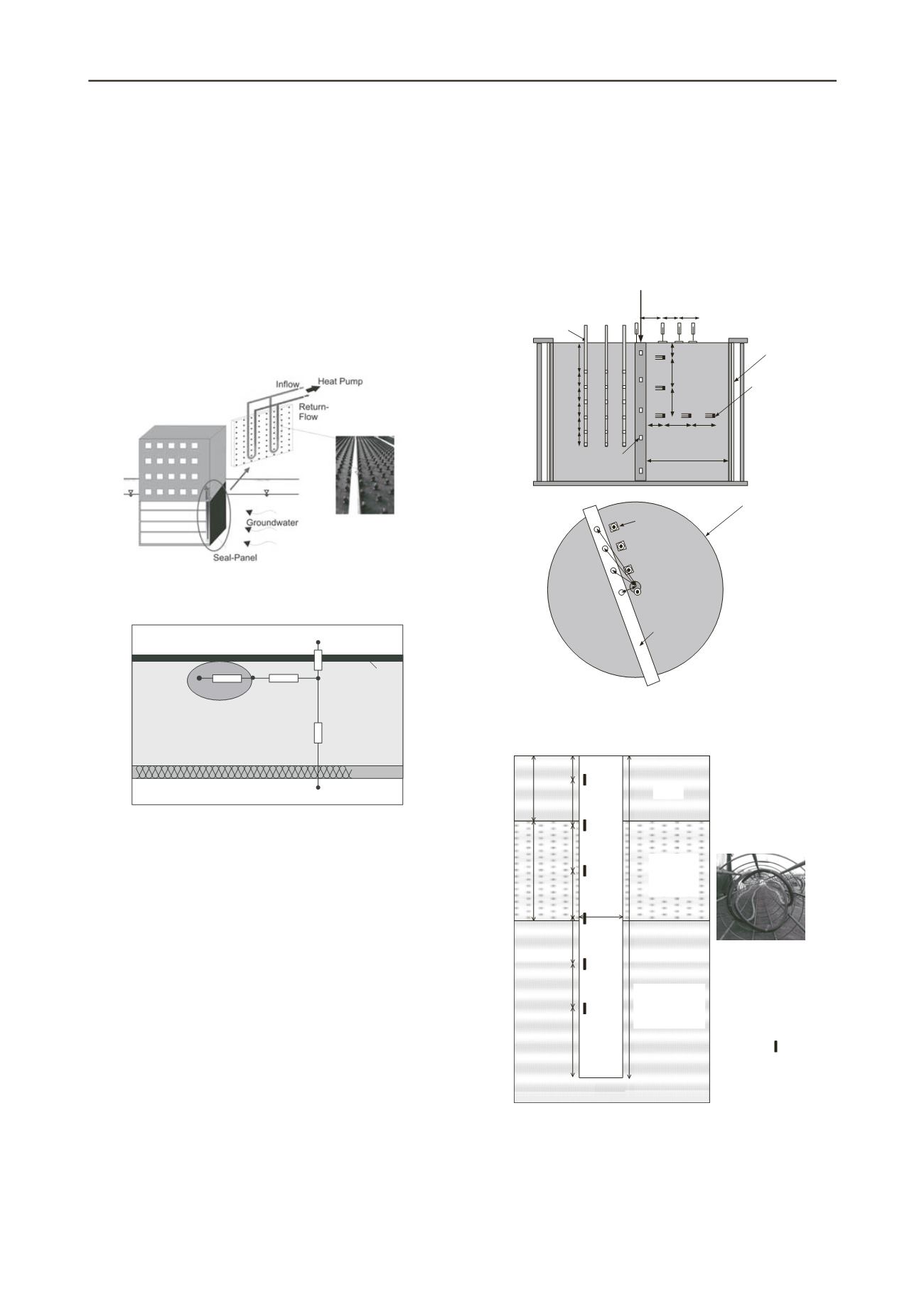

In the second example, Ziegler and Kürten described the use

of thermo-active seal panels with integrated heat-exchange

pipes (Figure 13) used in underground structures in direct

contact with groundwater. The authors tested the efficiency of

the panels through laboratory experiments. They noted the

importance of heat transfer between soil and heat exchanger for

achieving high efficiency. Because both these examples require

plane heat-flow models (instead of axisymmetric models) to

describe the heat flow, Ziegler and Kürten introduced a new

equivalent thermal-resistance model (Figure 14) for describing

heat transfer through plane structures.

Figure 13. Thermo-active seal panel (Figure 2 of Ziegler and Kürten).

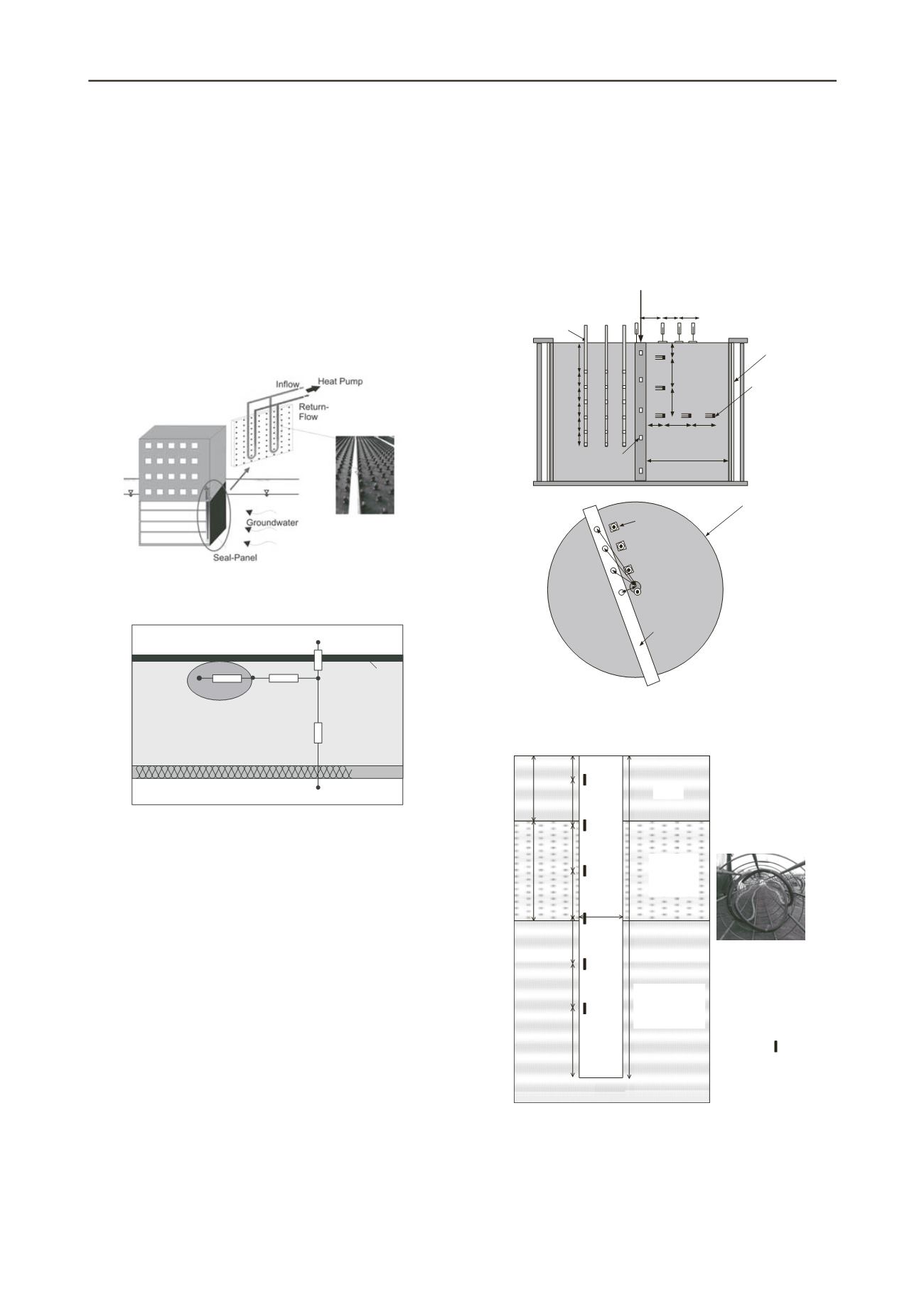

Sealing

Concrete

Insulation

Room

T

1

T

2

T

C

T

W

T

m

R

Pipe

R

X

R

W,1

R

W,2

Figure 14. Equivalent star-network thermal resistance model for

thermo-active seal panel (Figure 7 of Ziegler and Kürten).

The problem of energy piles is more complicated than that

of geothermal heat pumps because of the coupled thermo-

mechanical response. The coupled behavior of energy piles is

highlighted in the study by McCartney et al. in which they

investigated the impact of the pile-head boundary condition on

the response of end bearing geothermal piles using a centrifuge

test and monitoring a full-scale pile beneath an 8-story building

at Denver, CO, USA. In the centrifuge test (Figure 15), the pile

had a length of 533.4 mm and a diameter of 25 mm, and the

scaling factor was 24. The pile was maintained at a constant

temperature and then analyzed for thermally induced stresses

and strains with load (no restraint) boundary condition at the

head. The full-scale end-bearing drilled shaft (Figure 16) of

length 14.8 m and diameter of 0.91 m has three heat-exchanger

loops and is restrained at the head due to the presence of grade

beams. The authors recognized the difference in the soil profiles

and boundary conditions of the two piles and concluded that the

boundary condition at the pile head has a significant effect on

the magnitude and shape of stress distributions in energy piles.

Wang et al. also investigated through a field test the impact

of the coupled thermo-mechanical response of energy pile on its

capacity. A full-scale in situ geothermal energy pile equipped

with ground loops for heating and cooling, multi-level

Osterberg cells, thermistors, strain gages and transducers was

installed at Monash University, Australia in an unsaturated, very

dense sand profile. It was observed that the shaft capacity

increased when the pile was heated and returned to its initial

value when the pile was cooled (see Figure 17). The authors

noted that energy piles have the potential to reduce the energy

demand in built structures. They concluded that further research

is required to understand the pile shaft behavior in different soil

conditions and to assess the thermal properties of the energy

pile ground heat exchanger and the surrounding soil for

different field conditions.

Insulation

Thermocouple

profile probes

Strain gauges/

Thermocouples

Building

Load

LVDTs

Support beam

for LVDTs and

thermocouple

profile probes

5.5D

50.8

mm

88.9

mm

76.2

mm

38.1 mm

126.2 mm

102.4 mm

LVDTs

(Surface

deflections)

76 mm

140 mm

216 mm

292 mm

114

mm

38.1

mm

76.2

mm

15.4

mm

30.4

mm

Dielectric

sensors

(water

content and

temperature)

605-mm

diameter

aluminum

cylinder

Figure 15. Schematics of the centrifuge-scale energy foundation test

(Figure 2 of McCartney et al.).

Figure 16. Soil stratigraphy and layout of energy drilled-shaft

instrumentation (Figure 3 of McCartney et al.).

Suryatriyastuti et al. presented a theoretical analysis of

geothermal piles subjected to heating-cooling cycles and

mechanical loading. Two analysis methods were presented to

predict the evolution of pile head displacement, axial stresses,

and the mobilized soil resistance. The first method is commonly