3346

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

to implement as with U-pipes due to HDPE pipe stiffness, and

(ii) they have nearly the same thermal performance. In these

large diameter GHEs, a relatively minor change in heat

extraction rate is suggested by the numerical results when the

total the flow rate through the GHE is increased. The rightmost

column in Table 3 summarises the numerical results of doubling

and tripling the flow rates in GHE with double U-pipes and

triple U-pipes respectively (the same fluid flow rate is applied to

each U-loop of the GHEs).

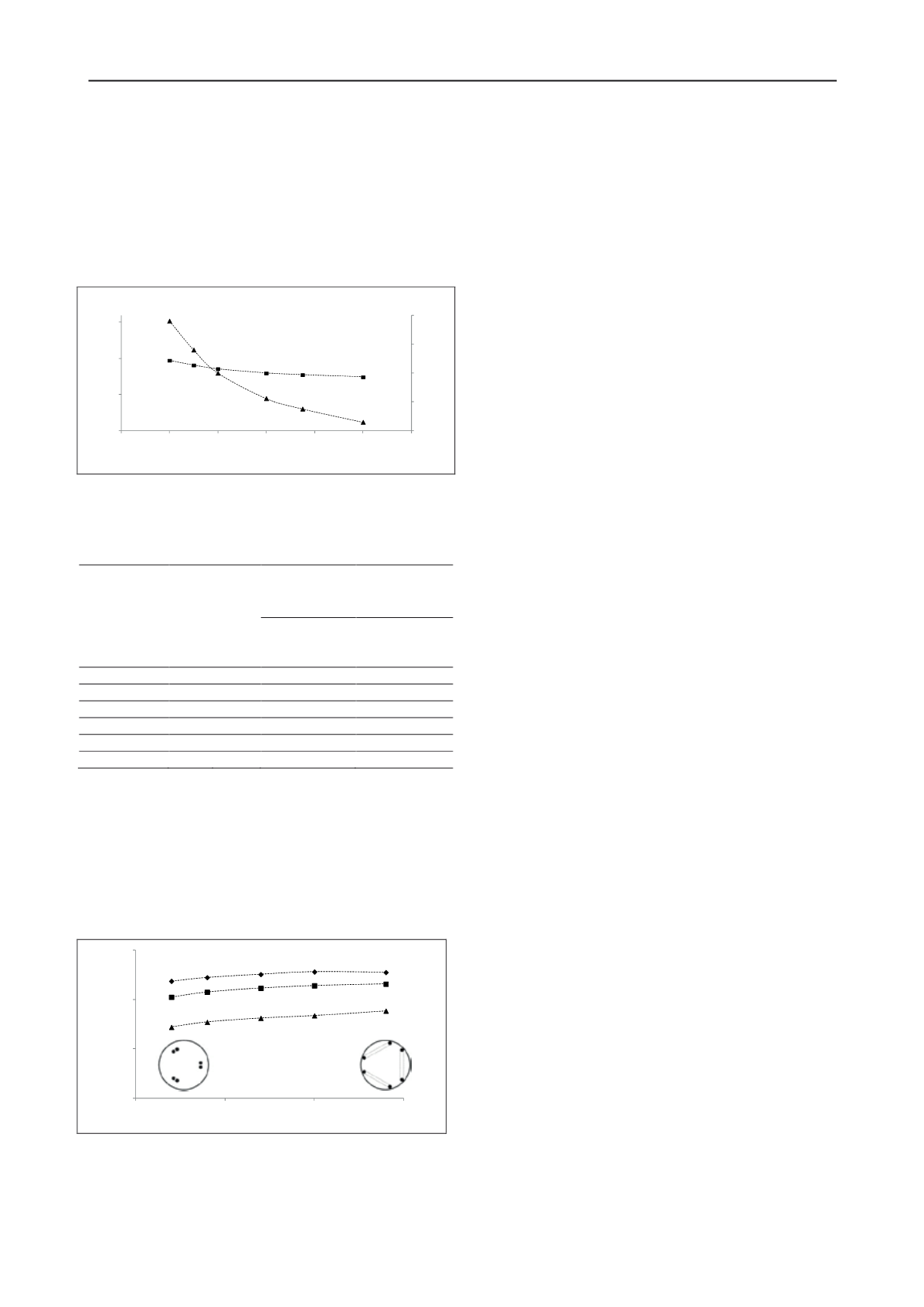

Figure 5. Heat extraction rate and outlet temperature in a spiral GHE

with different axial pitches.

Table 3. Comparison of spiral and U-pipes GHE thermal performance

for varying pipe lengths.

Geometry

Axial

Pitch

[m]

Pipe

length

[m]

Flow rate

of 14.5 l/min in

each GHE

Flow rate of

14.5 l/min in

each U-pipe

Heat extraction

rate [W/m]

Heat extraction

rate [W/m]

Spiral 1

0.2

180

48.63

48.63

Triple U

-

180

49.71

51.15

Spiral 2

0.3

120

45.35

45.35

Double U

-

120

44.07

45.10

Spiral 3

1

60

37.13

37.13

Single U-pipe

-

60

32.53

32.53

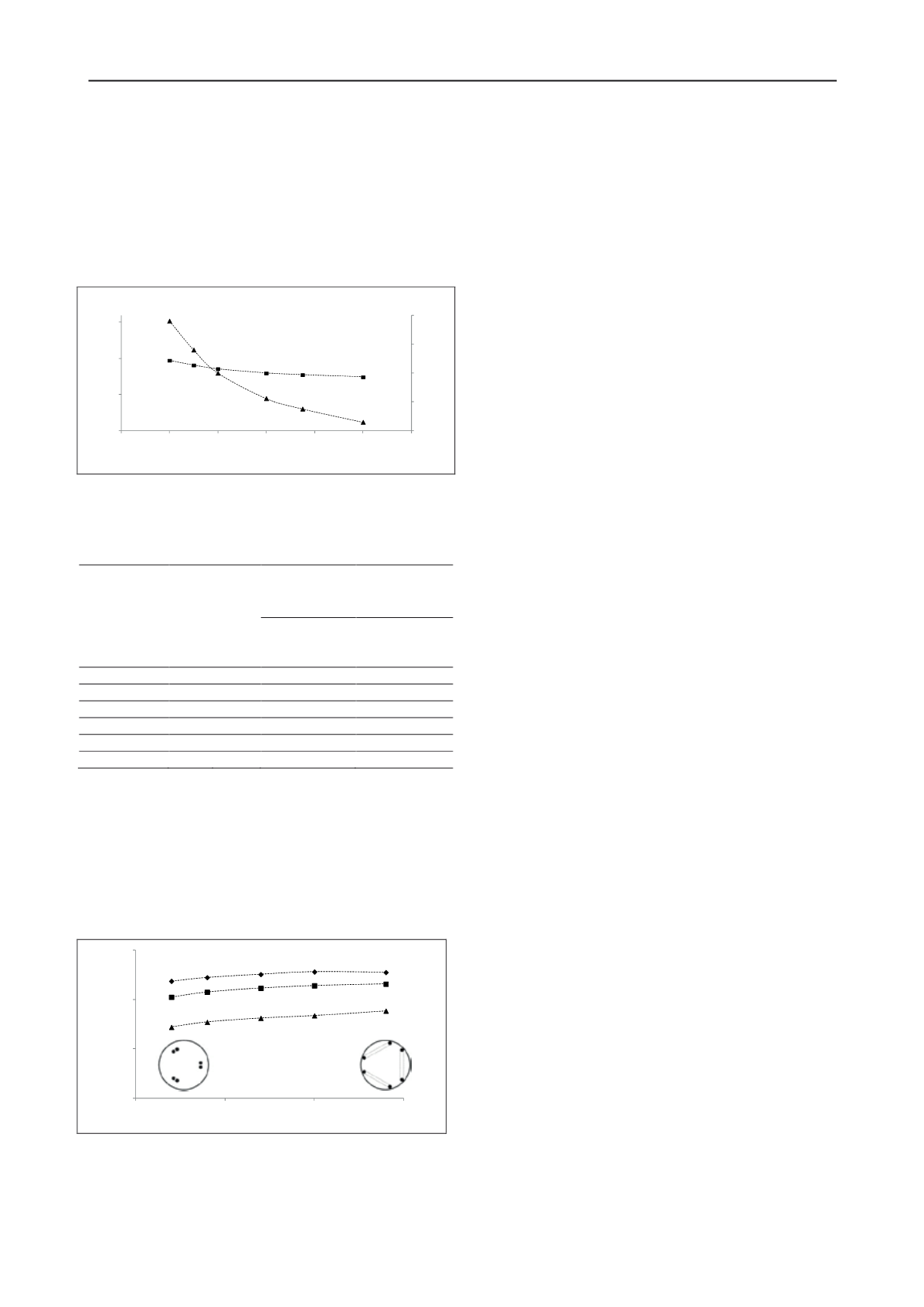

The previous observations will not vary significantly if

different pipe separations in the U-pipes are used. To investigate

the effects of pipe separation on GHEs thermal performance,

single, double and triple U-pipes with different inlet-outlet pipe

separations were simulated. Figure 6 shows variations of pipe

separation for multiple U-pipe GHEs and how this affects the

heat extraction rate. Pipe separation variations between S

S

=

0.04 m and S

L

= 0.28 m for the 0.46 m diameter GHE result in

heat extraction rate increasing about 7% to 23%.

Figure 6. Effect of pipe separation on heat extraction rate for GHEs with

single, double and triple u-pipes.

It is worth mentioning that pipe separation has a stronger

influence on GHEs with single U-pipe than that of a triple U-

pipe, the reason being that in multiple U-pipes, increasing the

separation reduces the thermal interference between inlet and

outlet pipe of one U-pipe but at the same time increases mutual

interference between different U-pipes inside the GHE.

4 CONCLUSIONS

The outcomes of the multiple simulations performed in this

work show that GHE configuration may affect system

efficiency. Based on numerical results in a large diameter

borehole and for a given borehole length, it seems that as long

as the same pipe length is embedded inside the borehole,

thermal performance of the system is not significantly related to

pipe geometry placement, at least for the spiral and multiple U-

pipes analysed here. However, comparison of small diameter

GHEs with double and double cross U-pipe shows between 8%

to 23% better performance of the former one. Nevertheless, the

addition of a second U-pipe to both small and large diameter

GHEs achieves significant (40-90%) additional thermal

performance and could lead to important cost savings when

compared with single pipe systems due to reduced drilling

costs.

Heat extraction rates tend to increase rapidly as the Reynolds

number increases in the laminar regime; however, the rate of

increase reduces with Reynolds numbers once the flow becomes

turbulent. This indicates that when considering the size of the

fluid circulating pump and its operational cost, highly turbulent

fluid flow will not necessarily result in a more efficient system

overall. Regardless of number of U-pipes inside the GHE, larger

pipe separation improves the system efficiency. However, as the

number of U-pipes in the GHE increases, this effect becomes

less pronounced due to thermal interference occurring between

different U-pipes.

5 ACKNOWLEDGEMENTS

This work is partially supported by funding of $1.6 M from

the Victorian Government’s Energy Technology Innovation

Strategy (ETIS) Pilot Demonstration Program (SEPD) and The

University of Melbourne’s Research Collaboration Grant.

6 REFERENCES

Banks, D. 2008. An introduction to thermogeology: ground source

heating and cooling, Wiley-Blackwell.

Bernier, M.A. 2001. Ground-coupled heat pump system simulation.

ASHRAE Transactions

107, 605-616.

Deerman, J. 1990. Simulation of vertical U-tube ground-coupled heat

pump systems using the cylindrical heat source solution.

ASHRAE

Transaction: Research

3472, 287-295.

Gao, J., X. Zhang, J. Liu, K.S. Li and J. Yang 2008. Thermal

performance and ground temperature of vertical pile-foundation

heat exchangers: A case study.

Applied Thermal Engineering

28(17), 2295-2304.

Hamada, Y., H. Saitoh, M. Nakamura, H. Kubota and K. Ochifuji 2007.

Field performance of an energy pile system for space heating.

Energy and Buildings

39(5), 517-524.

Jun, L., Z. Xu, G. Jun and Y. Jie 2009. Evaluation of heat exchange rate

of GHE in geothermal heat pump systems.

Renewable Energy

34(12), 2898-2904.

Lamarche, L. and B. Beauchamp 2007. A new contribution to the finite

line-source model for geothermal boreholes.

Energy and Buildings

39(2), 188-198.

Marcotte, D. and P. Pasquier 2008. Fast fluid and ground temperature

computation for geothermal ground-loop heat exchanger systems.

Geothermics

37(6), 651-665.

Miyara, A., K. Tsubaki, S. Inoue and K. Yoshida 2011. Experimental

study of several types of ground heat exchanger using a steel pile

foundation.

Renewable Energy

36(2), 764-771.

6.1

6.2

6.3

6.4

6.5

0

25

50

75

0

0.2

0.4

0.6

0.8

1

1.2

T

out

[

°

C]

Heat extraction rate [W/m]

Axial pitch [m]

0

20

40

60

0.00

0.10

0.20

0.30

Heat extraction rate [W/m]

Pipe separation [m]

HER

T

out

Single

Double

Triple

S

S

S

L