3381

Technical Committee 307 + 212 /

Comité technique 307 + 212

Heating tests were performed on the energy foundation in

the layer of Bonny silt (USCS classification of ML) compacted

at a gravimetric water content of 14% to a dry density of

1451 kg/m

3

. An axial stress of 384 kPa was applied to the head

of the foundation using a feedback-controlled electric motor.

This motor permits the load to be maintained constant but

permits free displacement. This implies that the value of K

h

for

the centrifuge-scale foundation should be close to zero. A heat

pump, operated outside the centrifuge, was used to control the

temperature of the fluid being circulated through the scale-

model foundations. Details of the heat control system are

provided by Stewart (2012).

3.2

Full-Scale Energy Foundations

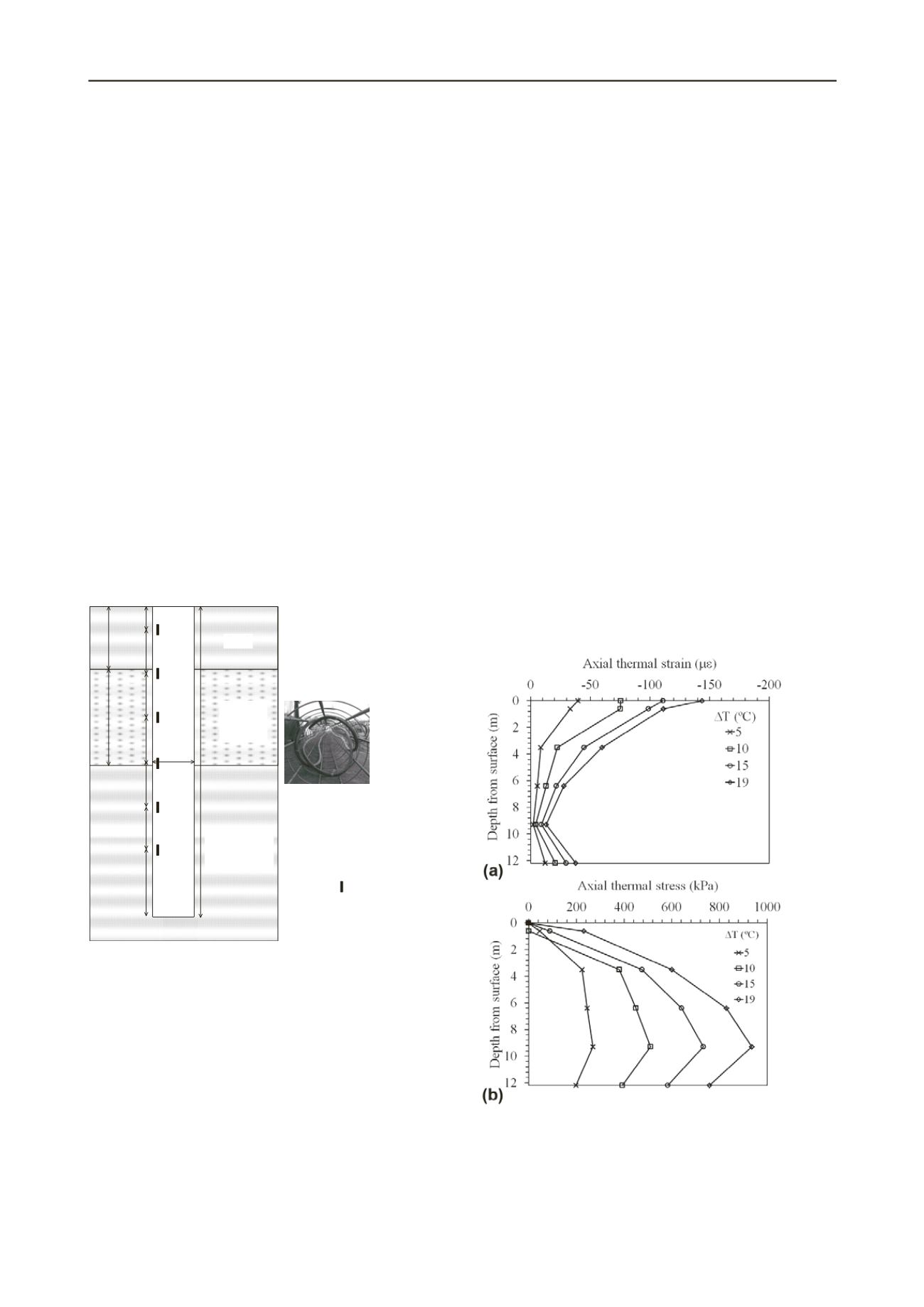

Two drilled shaft foundations installed as part of the new

Denver Housing Authority senior residential facilitywere

converted into energy foundations. The energy foundations

were coupled into a conventional GSHE system which was

already being incorporated into the building. This paper focuses

on the results of one of the drilled shafts,having a length of 14.8

meters and a diameter of 0.91 meters, that includes 3 heat

exchanger loops. The shaft consists of a full-length reinforcing

cage with nine #7 vertical reinforcing bars tied to #3 lateral

reinforcing hoops spaced 0.36 meters on center. A schematic of

the drilled shaft within the soil profile is shown in Figure 3. The

drilled shaft functioned as rock-socketed, end-bearing elements

in bedrock, with an expected load of 3.84 MN.The grade beams

attached to the top of the foundation likely provided a non-zero

stiffness to the head of the foundation (K

h

> 0).

Foundation A

FILL

SAND

AND

GRAVEL

CLAYSTONE

(Denver Blue

Shale)

FINISHED GRADE

3 Heat Exchanger

Loops

3.8 m

2.0 m

2.1 m

4.6 m

3.0 m

2.2 m

2.1 m

2.1 m

1.1 m

0.91 m

dia.

14.8 m

Vibrating

wire strain

gauge

locations

3 heat

exchange

loops

Figure 3.Soil stratigraphy and layout of foundation instrumentation

At the site, urban fill extends from grade to a depth of

approximately 3 meters and consists of slightly moist, medium

dense, clayey sand with gravel. Beneath the fill, non-expansive,

medium dense, silty, sand and gravel extended to a depth of

approximately 7.6 meters below grade. Following the sands and

gravels, the subsurface conditions consisted of hard sandy

claystone bedrock from the Denver formation. Because of the

potential for caving during drilling through the overburden and

possible perched ground water conditions, a cased-hole method

was chosen for installation of the drilled shaft foundations at the

site. Groundwater was observed near the depth of the claystone.

The heat exchanger system in the energy foundation consists

of 44 mm-diameter polyethylene tubing attached to the inside of

the reinforcing cages. The drilled shaft contains a total of 82.3

linear meters of tubing configured into three loops running the

length of the reinforcing cage. The heat exchanger tubing was

routed along the inside perimeter of the reinforcing cage to

avoid crossing the diameter of the cage, which could block

concrete flow or cause segregation of concrete. Equal angular

spacing of the tubing was maintained to ensure relatively

uniform temperature along the circumference of the shafts. Six

vibrating wire concrete-embedment strain gauges with attached

thermistors were incorporated into the foundation to monitor

temperature and axial strain distributions with depth, although

one gauge was damaged. The supply and return temperatures of

the heat exchanger fluid were also monitored. More information

is provided by McCartney and Murphy (2012).

4 STRAIN DISTRIBUTIONS

4.1

Centrifuge-Scale Energy Foundations

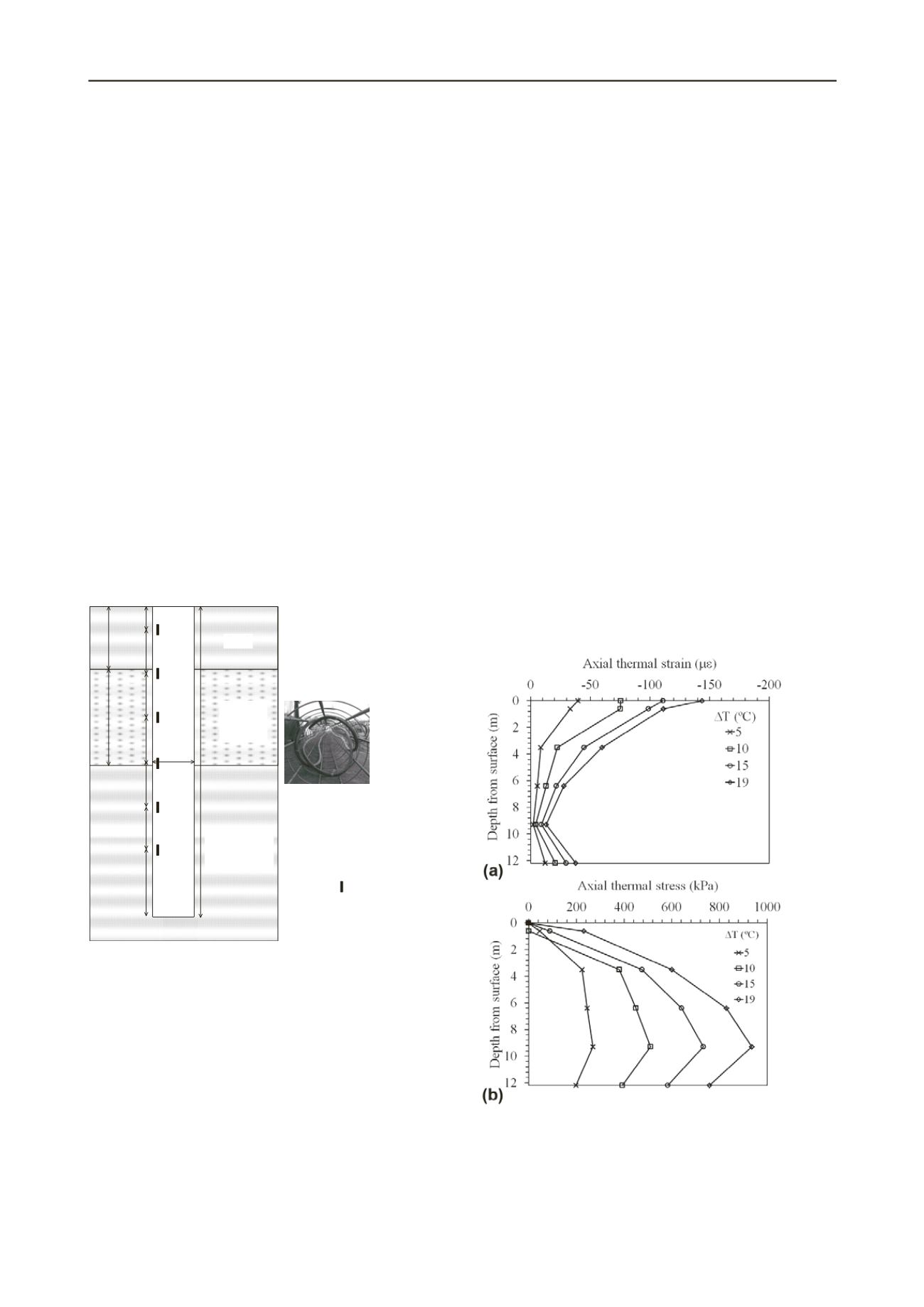

The axial thermal strain distributions in the centrifuge-scale

energy foundation after heating to different changes in

temperature above the ambient temperature of 20

°

C are shown

in Figure 4(a). Heating leads to a relatively uniform increase in

negative axial strain throughout the foundation, indicating

thermal expansion. The smallest strains are located near the toe

of the foundation, which is as expected due to the rigid end

restraint. The axial strains at the very top of the foundation

represent the thermal strain for free expansion of the foundation

(

c

T). The measured strains are consistent with these

theoretical values, and confirm that the top of the foundation

can expand freely. An upward displacement in prototype scale

of 1 mm was observed. The thermal axial stresses were

calculated from the thermal strains using Equation 1. The

location of minimum strain (and maximum stress) reflects the

null point for the foundation, which is approximately at the

bottom of the foundation. The trend in stress approaches zero at

the top of the foundation, supporting the conclusion that K

h

= 0.

Figure 4. Centrifuge results: (a) Axial strains; (b) Axial stresses

4.2

Full-Scale Energy Foundations

During operation of the heat pump between March and May

2012, the temperature of the foundation was relatively uniform,

and involved both heating and cooling. The strains induced in

the foundation during different average changes in foundation

temperature are shown in Figure 5(a). Similar to the centrifuge-