3380

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

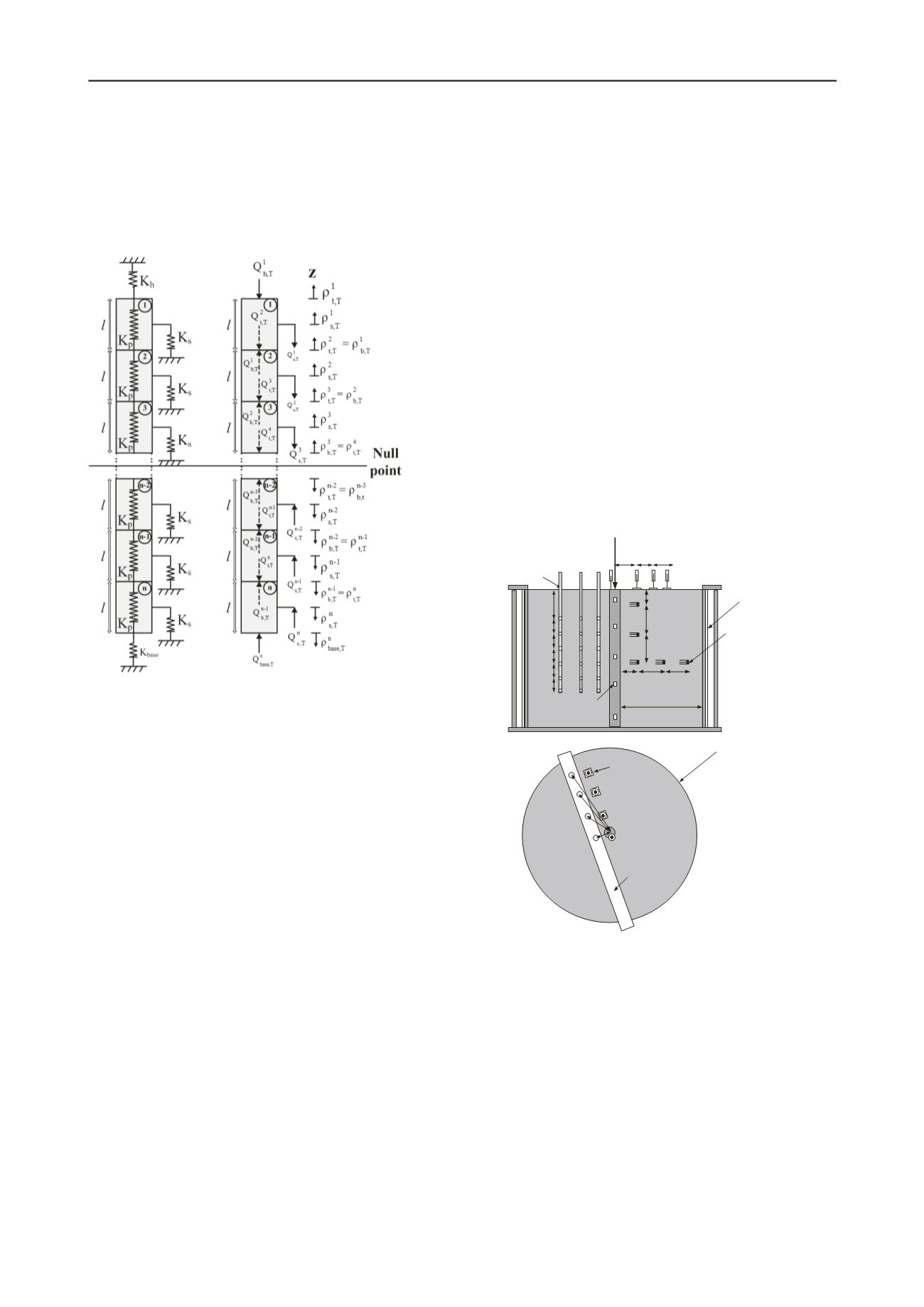

transfer analysis, a spring at the head of the foundation is used

to represent the constraint of a foundation by the overlying

building and grade beams. During heating, the foundation will

expand about a null point, the location of which depends on the

distribution of side shear values (K

s

) and the magnitude of the

end stiffness (K

base

) and head stiffness (K

h

). An iterative

approach can be used to ensure equilibrium between forces Q

and compatibility between displacements

.

Figure 1. Thermo-mechanical load-transfer analysis (Plaseied 2012)

If strain gauges are used to monitor strains in the

foundations, the thermal axial strains within a foundation can be

obtained by subtracting the mechanical strains occurring due to

an applied load (i.e., the weight of a building). Depending on

the type of strain gauge, different thermal correction factors

may need to be applied (McCartney and Murphy 2012;

McCartney and Stewart 2012). The thermal axial stresses at any

point in the foundation

T

can be defined as follows:

T

= E(

T

-

c

T)

(1)

where E is the Young’s modulus of reinforced concrete,

T

is

the measured thermalaxial strain,

c

is the coefficient of thermal

expansion of reinforced concrete, and

T is the change in

temperature. The value of

c

T represents the maximum axial

strain possible in the energy foundationfor unrestrained

conditions, and is negative (expansive) during heating.

3 FOUNDATION CASE STUDIES

3.1

Centrifuge-Scale Energy Foundation

The centrifuge-scale energy foundation evaluated in this study

has a length of 533.4 mm and a diameter of 25 mm, and was

installed in the center of a cylindrical container filled with a

layer of unsaturated Bonny silt. The base of the foundation rests

on the base of the container, providing a zero-displacement or

end-bearing bottom boundary condition. The centrifuge test was

performed at acentrifugal acceleration of 24, so the model-scale

foundation is intended to represent a prototype-scale foundation

having a length of 12.8 meters and a diameter of 1.2 meters.

Although it is understood that heat flow cannot be scaled in a

similar manner to geometry, stresses and strains, the thermally-

induced stresses and strains are governed by the restraint

provided by the surrounding soil, which depends on the stress

state. Accordingly, it is expected that the thermally-induced

stresses and strains will scale in a similar manner to mechanical

stresses and strains. Accordingly, centrifuge tests involved

maintaining the foundation at a constant temperature and

waiting for thermally induced stresses and strains to stabilize.

The model energy foundation was precast outside of the soil

layer due to the large amount of instrumentation, cables, and

heat exchanger tubing within the assembly. This also permits

the foundation to be tested outside of the soil layer to

characterize their thermal and mechanical properties. The

reinforcing cage for the model foundationwas constructed from

a hoop of reinforced wire mesh. A cardboard tube having an

inside diameter of 50.8 mm was used as a form for the

foundation, permitting a concrete cover of 5 mm on the sides

and 12.7 mm on the top and bottom. A total of three heat

exchanger loops (3 inlets and 3 outlets) was installed in the

foundation so that the distribution of heat across its

circumference would be as uniform as possible. Embedded

strain gauges and thermocouples were attached to the

reinforcement cage of the model foundation at the locations

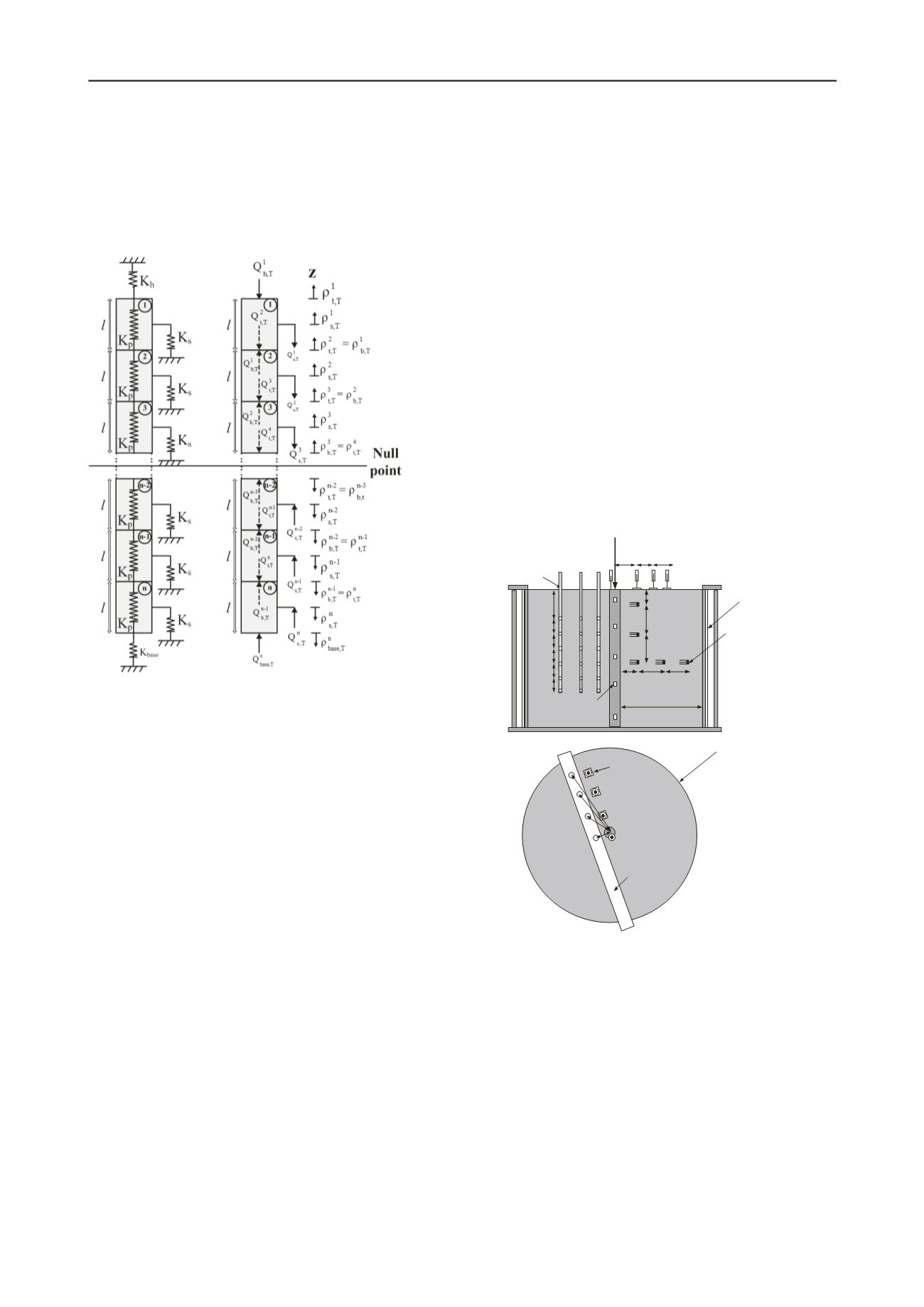

shown in Figure 2. Linearly-variable deformation transformers

were used to measure the axial displacement of the foundation

and the soil surface. The distribution in temperature was

measured using thermocouple profile probes and dielectric

sensors (also used to monitor changes in volumetric water

content of the soil). Additional details of the instrumentation are

presented by McCartney and Stewart (2012).

Figure 2.Schematics of the centrifuge-scale energy foundation test

A comprehensive set of characterization tests were

performed on the pre-cast drilled shaft outside of the soil in a

load frame at 1-gravity to determine the mechanical and thermal

properties of the reinforced concrete. These results from these

tests are reported in detail by Stewart (2012). The first test

involved application of incremental axial loads under room

temperature conditions, taking care to properly level the

foundation and center the load to avoid bending. The

mechanical strains encountered during application of an axial

load of 700 kPa were variable. The Young’s modulus

determined using the corrected strain data was 7.17 GPa. The

foundation was then heated to a temperature of 62 °C by

circulating fluid through the heat exchange tubes within the

foundation while maintaining a constant axial stress of 439 kPa.

The foundation was permitted to freely expand under this axial

stress, permitting definition of the coefficient of linear thermal

expansion of the foundation (

c

= -7.5

/°C, where

is

micro-strain, with compressive strain defined as positive).