3176

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

with water in the capillary state. The most suitable state for

pellet formation is the capillary state.

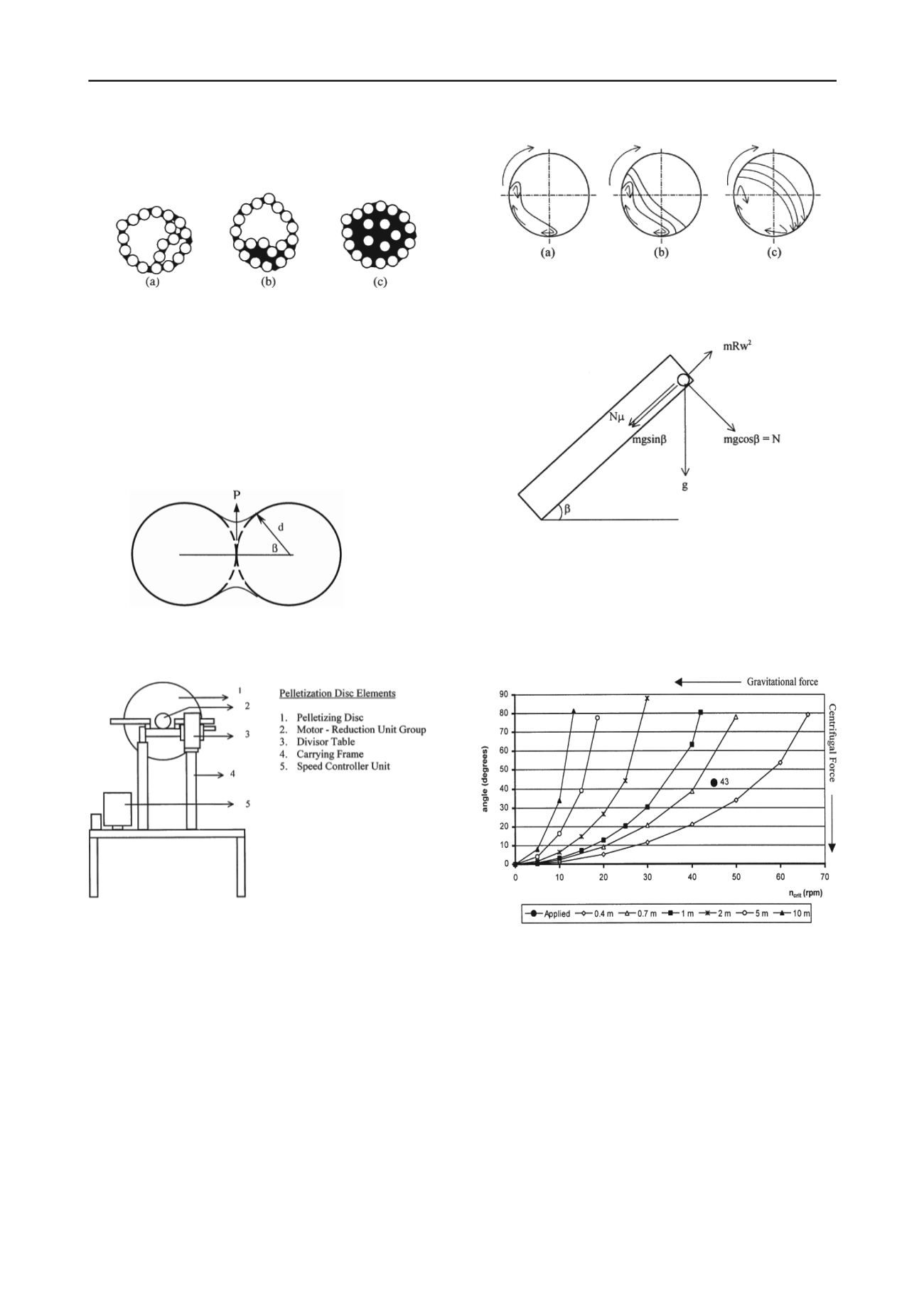

Figure 1. Mechanism of pellet formation; a) the pendular state; b) the

funicular state; c) the capillary state.

The formation of capillary force between two grains is

presented in Figure 2. The grain diameter of the powder

material influences the magnitude of the surface tension force;

small grain diameter is necessary to create enough pulling force

to initiate agglomeration. Agglomeration can be achieved by

drum or disc pelletizers. A typical disc pelletizer designed and

manufactured for this study is presented in Figure 3 (Doven

1998).

Figure 2.. Surface tension force created by water bridge between two

particles

.

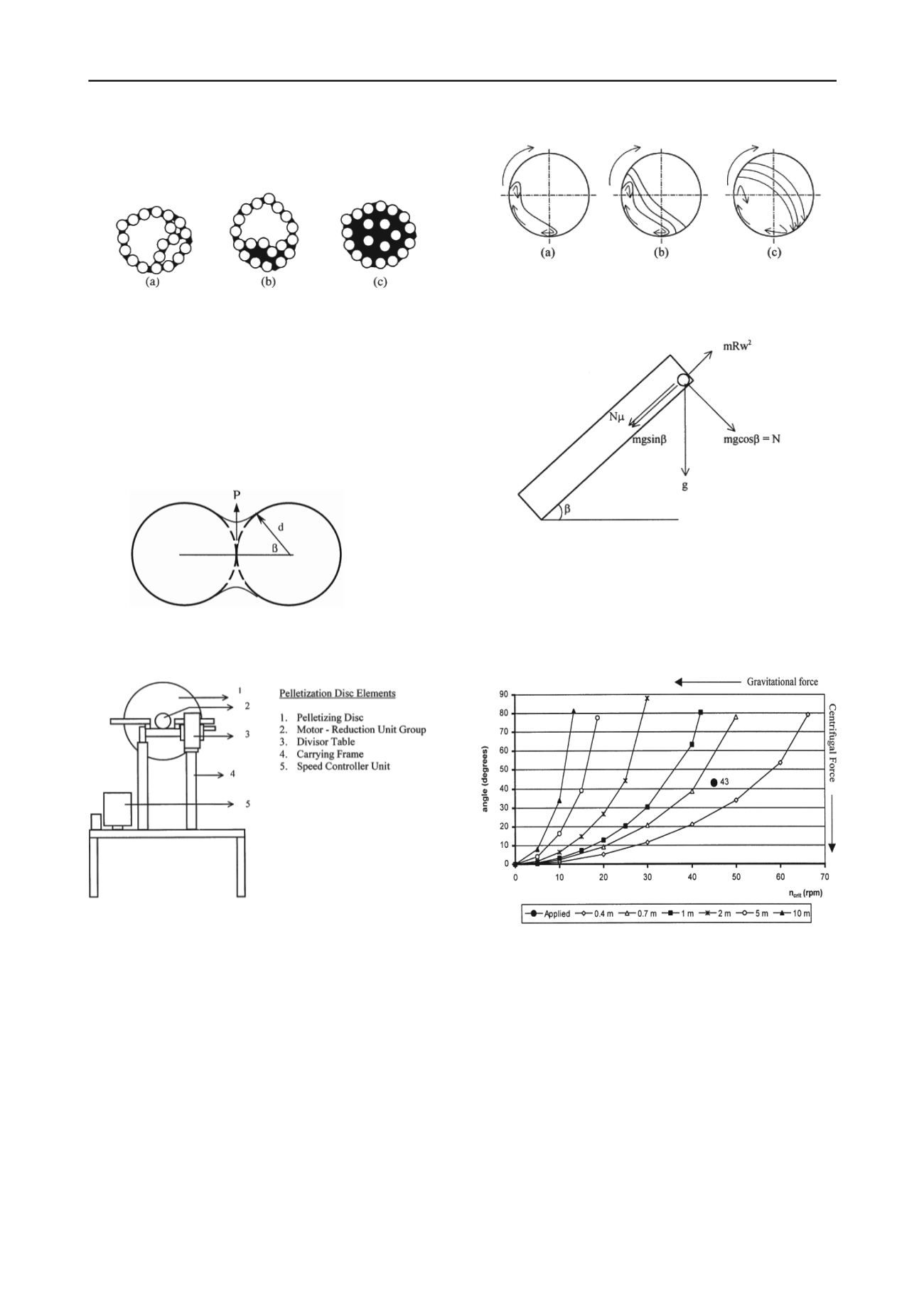

Figure 3. The sketch of disc pelletizer (back view).

The revolution speed of the disc can be controlled between 0

and 70 rpm and the angle of the disc plane to the normal can be

adjusted between 0 and 90 degrees. The diameter of the disc is

0.40 meters and scraping blades are placed from center to one

edge at 0.06 m intervals. During the revolution of the disc the

grains pulled by surface tension are compacted further. The

agglomerated grains hit to the scraping blades, falling free to the

bottom section of the disc. This free fall action compacts the

agglomerated product more. This repeated revolving and free

fall action densifies and makes the agglomerated product

stronger for handling. The motion of the grains in the disc is

presented in Figure 4. The forces applied to the grains during

pellet formation are presented in Figure 5. To achieve the most

suitable pelletization process; the revolution speed and the angle

of disc plane to the normal should be set in a manner to avoid

the dominancy of gravitational or centrifugal forces (Figure 6).

Figure 4. Motion of material in disc pelletizer revolving at various

speeds.

Figure 5. Forces acting on an individual pellet during pelletization

process.

When the gravitational and centrifugal forces are in

equilibrium then the normal force exerted by the pellet

converges to zero and the following equation prevails.

m x g x sin β = m x R x W

2

(1)

Figure 6. Variation of operation angle with respect to diameter of

pelletization disc and critical revolution speed.

For various disc diameters the effect of operating angle and

revolution speed on centrifugal and gravitational forces are

presented in Figure 6.

2 PHYSICAL AND ENGINEERING PROPERTIES OF THE

MANUFACTURED PELLETS

Turkey produces more than 17 million tons of fly ash annually.

The fly ash used in the presented studies is obtained from Soma

Coal Burning Thermal Power Plant in the west part of Turkey.

The typical chemical composition of Soma fly ash is given in

Table 1. The physical properties of manufactured fly ash pellets

are presented in Table 2. The water absorption of the produced

ellets is high.

p

Table 1. The chemical composition of Soma Fly Ash.