3177

Technical Committee 307 /

Comité technique 307

Per cent

SiO

2

50.5

Al

2

O

3

23.7

Fe

2

O

3

5.8

CaO

9.3

MgO

2.6

SO

3

1.4

Loss on Ignition

2.2

Soma fly ash is self cementitious and it will harden without

the need of another binder. The physical properties of the

manufactured fly ash pellets are given in Table 2. The typical

fly ash pellets are given in Figure 7.

Table 2. Physical properties of the fly ash pellets.

Unit weight

9.6 kN/m

3

Water absorption

31.4 %

Specific gravity

2.17

Bulk specific gravity

1.29

Figure 7. Manufactured fly ash pellets.

Table 3. Engineering properties of the fly ash pellets.

Optimum moisture content

Dry unit weight (Standard Proct)

34.4 %

11.96 kN/m

3

Angle of internal friction

29.4°

California Bearing Ratio

58 %

Soundness loss of weight

9.5- 4.75 mm

9.0 %

Soundness loss of weight

19- 9.5 mm

7.9 %

Tables 1 through 3 show that fly ash pellets formed with

cold bonding technique have similar engineering properties to

that of soils. With no additional binder like lime or cement, self

cementitious fly ash pellets have acceptable engineering

properties. The soundness tests were conducted using sodium

sulphate. Less than 12 percent weight loss after sodium sulphate

treatment is allowable for concrete applications. The durability

performance of the manufactured aggregates is adequate even

for more demanding applications like concrete production.

From geotechnical point of view, the manufactured pellet

aggregates have properties similar to those of granular soils

except high water absorption value.

3 CRUSHING BEHAVIOR OF MANUFACTURED

PELLETS

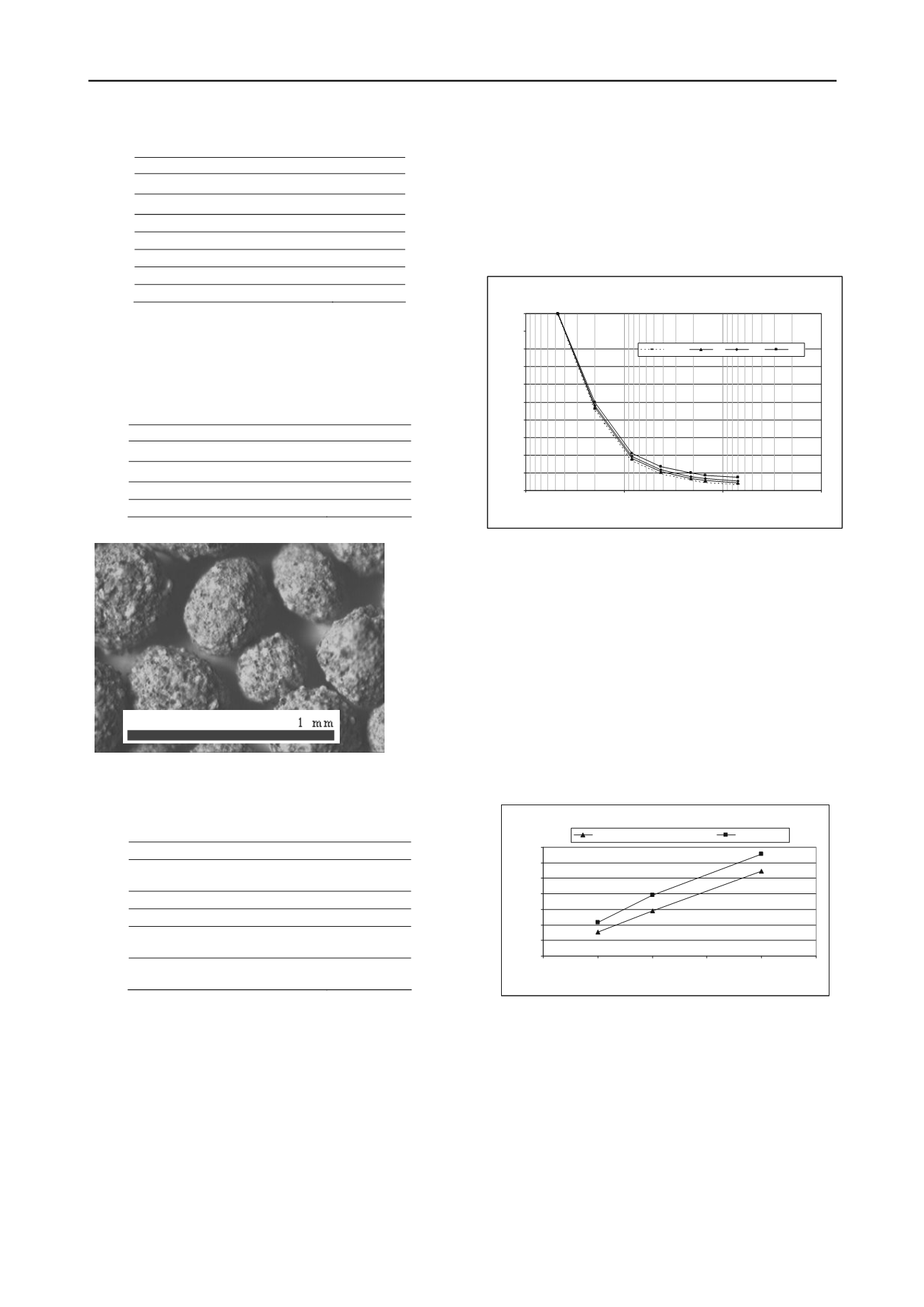

To demonstrate the effect of aggregate crushing sieve analyses

were performed before and after direct shear testing of fly ash

pellets at 50, 100 and 200 kPa normal stress. The change in

grain size distributions before and after execution of the direct

shear tests are given in Figure 8 (Danyldz 2007).

FA

0

10

20

30

40

50

60

70

80

90

100

0,010

0,100

1,000

10,000

Grain diameter (mm)

Percent finer

Before

50

100

200

Figure 8. The grain size distribution of fly ash pellets before and

after the conduction of direct shear test at a normal stress of 50, 100

and 200 kPa.

The fly ash pellets crushing behavior is similar to calcerous

sands. The measured crushing behavior does not pose a threat

for the engineering performance of the fly ash pellets for most

geotechnical applications.

4 SHEAR STRENGTH OF FLY ASH PELLETS

Direct shear tests are conducted on manufactured fly ash pellet

aggregates under 50,100 and 200 kPa normal stress

applications. Interface tests are conducted on split samples of

fly ash pellets and concrete. The internal friction angle and

interface friction angle plots are presented in Figure 9.

FA

0

20

40

60

80

100

120

140

0

50

100

150

200

250

Normal Stress (kPa)

Interface or internal Stress (kPa)

interface frcition between concrete

internal friction

Figure 9. Internal and interface friction angles of fly ash pellets and

pellet concrete interface.

product

e disc is

ns during

the most

the angle

to avoid

gure 6).

Turkey produces more than 17 million tons of fly ash annually.

The fly ash used in the presented studies is obtained from Soma

Coal Burning Thermal Power Plant in th west part f Turkey.

The typical chemical composition of Soma fly ash is given in

Table 1. The physical properties of manufactured fly ash pellets

are presented in Table 2. The water absorption of the produced

ellets is high.

p

Table 1. The chemical composition of Soma Fly Ash.