3178

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

6 CONCLUSIONS

FA

0

20

40

60

80

100

120

140

160

180

0

2

4

6

8

10

Horizontal displacement (mm)

Interface Stress (kPa)

200 kPa

100 kPa

50 kPa

Figure 10. Shear stress vs. horizontal displacement of manufactured

fly ash pellets.

Figure 11. Shear stress vs. vertical displacement of manufactured fly

ash pellets.

The shear stress vs. horizontal displacement and shear stress

vs. vertical displacement values of fly ash pellet aggregates are

presented in Figures 10 and 11 respectively. While dilation

behavior is observed under 50 and 100 kPa, contraction

behavior is seen under 200 kPa due to grain crushing.

5 SETTLEMENT BEHAVIOR OF PELLET AGGREGATES

The size of the silt sized powder wastes can be increased to sand

and gravel size by pelletization technique in large volumes and

low cost making the technique suitable for geotechnical

applications. In this study experience with self cementing fly

ash is presented, however the technique is applicable to other

silt sized powder wastes provided that adequate capillary forces

develop between the grains. For non self cementing fly ash,

binders like hydrated lime or cement can be used for

manufacturing. For higher performance needs the crushing

strength of the fly ash pellets can be improved by using lime or

cement additives. Surface treatment of pellets is possible using

water glass at reasonable cost. High water absorbtion values( 30

-35 per cent) place the manufactured granular material in an

unique place in clasical soil classification. The durability of the

aggregates is also satisfactory. With low unit weigh, free

draining behavior, and ease of compaction, the manufactured

soil has good potential for large volume utilization in

geotechnical applications. The geotechnical properties of the

manufactured soil ensures high stability. In addition to its

potential for utilization in large volumes, the manufactured soil

is a great tool for experimental research on crushable soils. It is

possible to control the size, shape, surface texture, roundness,

sphericity, crushing strength, unit weight, water absorption

properties of the powder materials to produce soil with target

engineering properties. This way by fixing one parameter at a

time it will be possible to study the effects of each parameter on

the engineering behaviour of natural soils. The cold bonding

pelletization technology is a low tech technology which requires

minimum capital investment and low operational costs. The

whole process can be automated. If the manufactured

aggregates are not used in a geotechnical application, a major

reduction in disposal costs is achieved by improving handling,

transportation, compaction and disposal in a dump site. Free

draining property, high stability and potential for reuse when

needed are other benefits of utilization.

FA

-0,5

-0,4

-0,3

-0,2

-0,1

0

0,1

0,2

0,3

0,4

0

2

4

6

8

10

Horizontal displacement (mm)

Vertical Displacement

(mm)

50 kPa

100 kPa

200 kPa

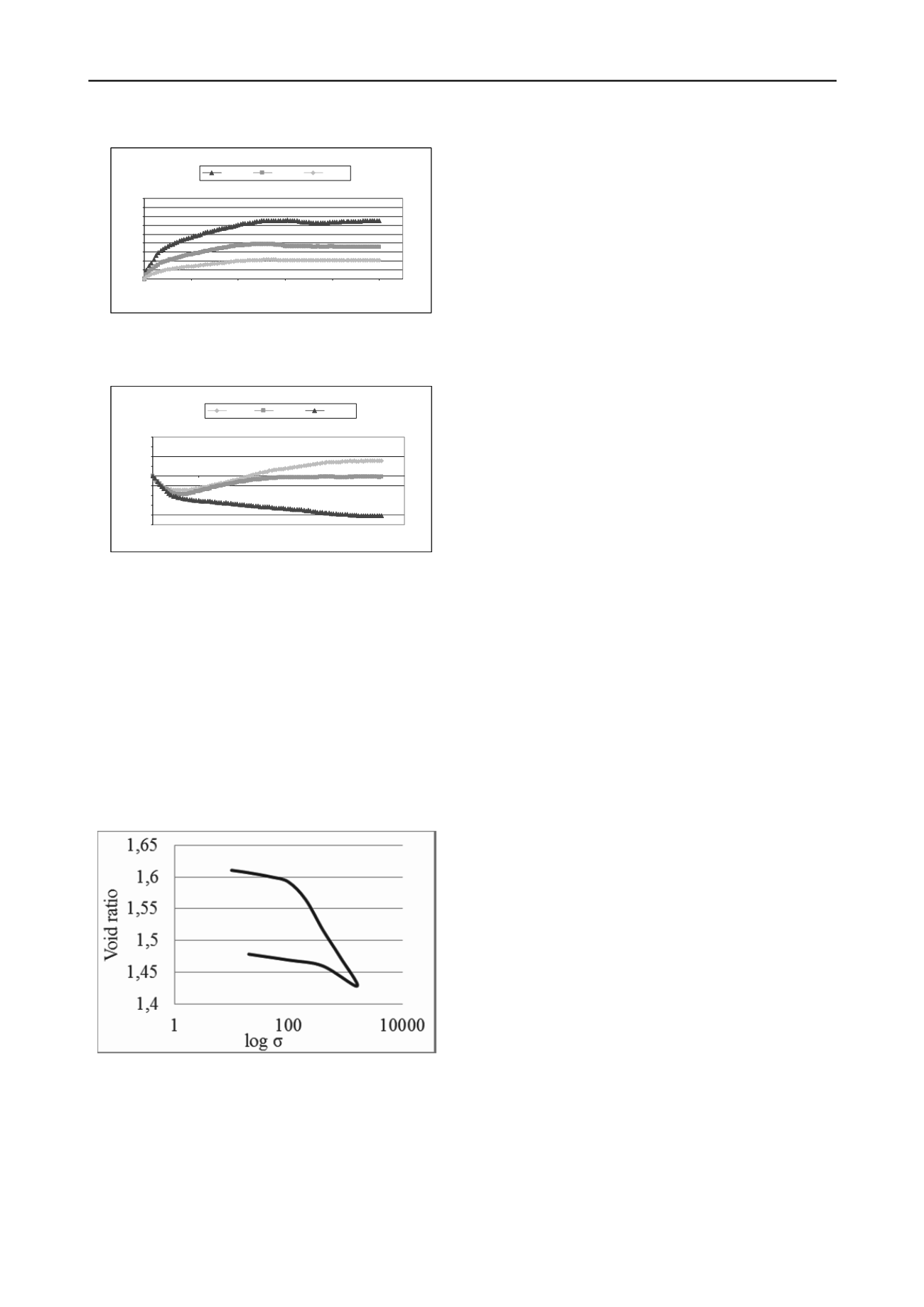

Manufactured fly ash pellet aggregates are placed in an

odometer and vertical stress of 25 to 1600 kPa is applied and

removed. The corresponding void ratio values vs. the applied

vertical stress are presented in Figure 12 (Erdurak 2011).

7 ACKNOWLEDGEMENTS

The studies presented above are conducted by PhD student Ata

Gurhan Doven; MSc students; Haydar Arslan, Egemen

Danyldz and Murat Cenk Erdurak with financial support

provided by Bogazici University Scientific Research Fund and

Turkish Scientific Research Council (TUBİTAK).

8 REFERENCES

Baykal G. And Doven A.G. 2000. Utilization of fly ash by pelletization

process; theory, application areas and research results.

Resources

Conservation and Recycling

30, 59-77.

Doven A.G. 1998. Lightweight fly ash aggregate production using cold

bonding technique. PhD Thesis. Bogazici University, İstanbul.

Erdurak M.C.2011. Artificial sand production for laboratory tests. MSc

Thesis Bogazici University, Istanbul

Danyldz E.2007. The interface behavior between granular soils and

concrete. MSc Thesis, Bogazici University. Istanbul.

Arslan H. 2003. The effect of grain crushing on the behavior of granular

materials. MSc Thesis. Bogazici University. Istanbul.

Figure 12. Odometer test results of fly ash pellets.

After the application of 100 kPa vertical stress the settlement

increases. Even for high embankment fills the settlement

magnitude is manageable.