3168

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

and the effects of varying the amount were investigated. The

proposed soil improvement technique is thus showing great

promise in sustainable construction. Nataatmadja and Illuri

(2009) prepared an artificially reconstituted soils of different

plasticity values by mixing fine sand and sodium bentonite. It

has been found that the addition of EPS granules into these soils

results in light-weight backfill materials, suitable for reducing

swelling pressure behind domestic retaining walls.

The current research was conducted to investigate the

recyclability of EPS packaging products in reducing swelling

pressures on structures foundation by using recycled EPS beads

as a mechanical admixer in replaced soils at their optimum-

moisture contents. Mixing recycled EPS beads with soil

replacement

is

introduced

an

environment-friendly

geomaterials. The applications of recycled EPS as a swell shrink

modifier as well as desiccation controller of expansive soils

were considered in this study. The quantitative evaluation also

whether recycled EPS beads provides significant benefits for

use in soil replacement to reduce swelling pressures was done

through an extensive experimental program.

2 MATERIALS

2.1

Replacement Soil

The replacement soil was sub-angular silica sand and classified

according to the unified soil classification (USCS) system as a

poorly-graded clean medium to fine sand (SP) with coefficient

of curvature (C

c

)= 1.73, coefficient of uniformity (C

u

)=3.6 ,

max dry density (

dmax

=19.2kN/m

3

) and optimum moisture

content (OMC)= 9%.

2.2

Expansive Soil

The expansive soil was a sodium Bentonite. The physical

properties for the used Bentonite are summarized in Table 1.

Table 1. Physical properties of the used Bentonite

Liquid Limit (LL) %

143

Plastic Limit (PL)%

47.6

Plasticity Index (PI) %

95.4

Free Swell (FS)%

96.7

Specific Gravity (Gs)

2.55

Max Dry Density (

dmax

) kN/m

3

14

Optimum Moisture Content (OMC) %

24

2.3

Recycled EPS Beads

For the present study, waste EPS beads were collected with

three different beads densities and particle sizes. Photo 1 shows

the beads's size compared to sand particles. The beads densities

and particle sizes are summarized in Table 2.

Table 2. Properties of EPS Beads

EPS Beads

400

500

600

Density (KN/m

3

)

0.10

0.16

0.20

Particle Size (mm)

5-6

4-5

1-3

3 COMPACTION CHARACTERISTICS OF SAND EPS

MIX

To study the compaction characteristics, standard Proctor

compaction tests were performed on a number of sand EPS

mixes. With the addition of EPS beads, the density of the

resulting composite is much lower than the original soils.

The EPS beads were added to the moist soil at a certain

percentage of the soil’s dry mass. Compaction tests of the sand

with EPS (SWEPS) composite were subsequently carried out

immediately after mixing the sand and EPS.

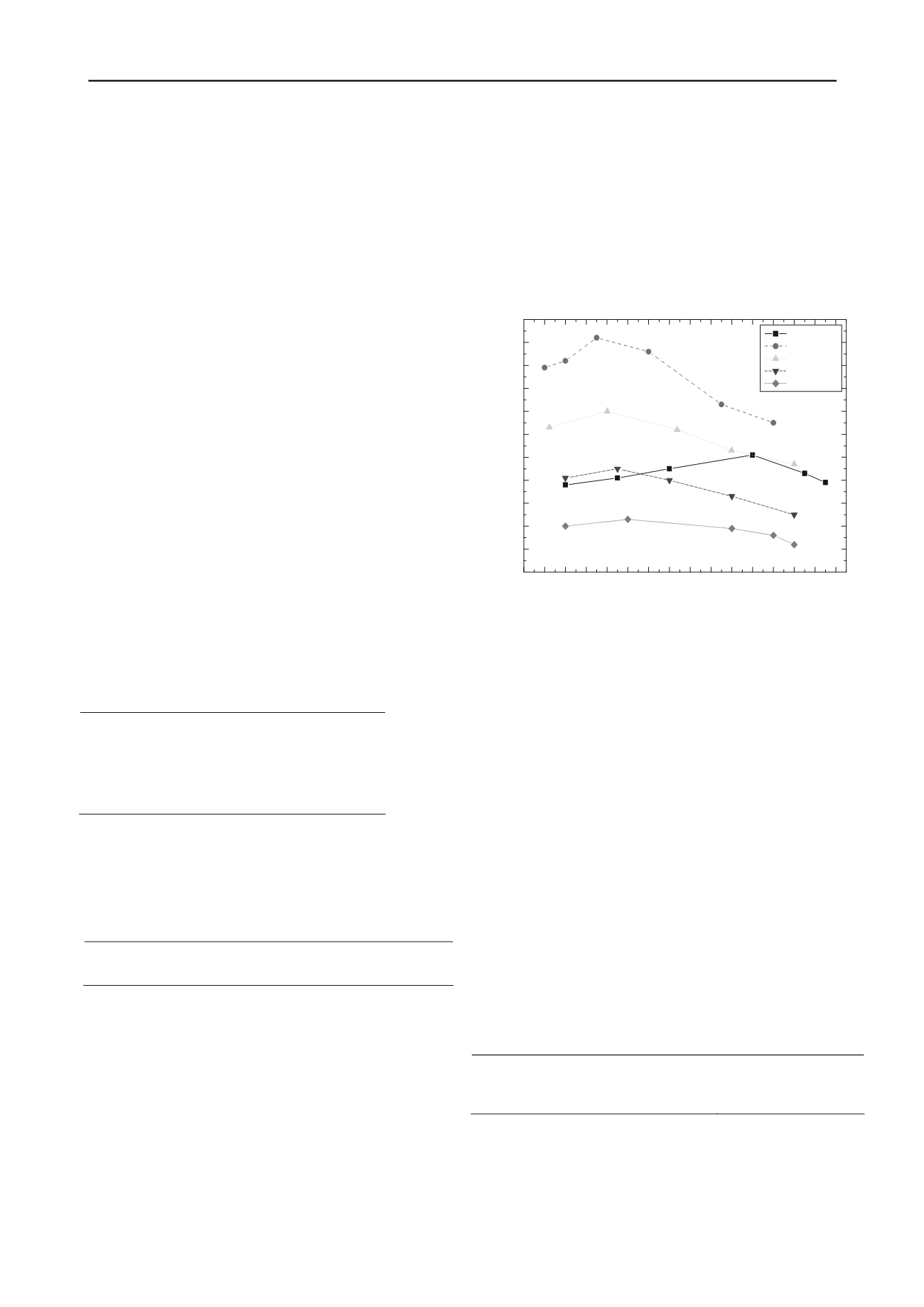

Compaction curves for mixes of sand with different percentages

of EPS beads are shown in Figure 1. From this figure, it can be

observed that with the addition of EPS beads the dry density of

the resulting mix varies considerably, it decrease with

increasing the beads content but there is no significant variation

in the optimum moisture content. This can be attributed to the

low bulk density and very low moisture absorbency of the EPS

beads. Since the beads are bulk in volume but very low in mass,

the mass of the soil-EPS composite is generally controlled by

the mass of the soil in the mix. Furthermore, as the moisture is

held within the soil particles, the optimum moisture content of

the mix is controlled by the optimum moisture content of the

sand. From previous stud it is found that the increase of EPS-

beads density increases the maximum dry density at the same

beads ratio, Abdelrahman,( 2009)

2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 32

10

11

12

13

14

15

16

17

18

19

20

Maximum Dry Density,

d

, kN/m

3

WC%

Bentonit

Pure sand

0.3% Beads

0.6% Beads

0.9% Beads

Figure 1. Compaction curves for mixes with sand and EPS contents

at density of t EPS beads = 0.16kN/m

3

4 EXPERIMENTAL WORK

4.1

Test Model

Experimental model consists of cylindrical soil sample

container with diameter is 15 cm and height = 18cm , two

vertical dial gages to measure the settlement and swelling ,

circular footing with different diameters. Vertical stress equal

to 30 kN/m

2

was applied on the footing which represented the

applied stress of three stories building.

4.2

Test Program

A series of tests were performed on circular footing with

different diameters rested on sand EPS mix replacement layer

with different ratios of EPS beads and layer thickness above

Bentonite layer both sand EPS mix replacement layer and

Bentonite layer were compacted at their optimum moisture

content (OMC). Mixing EPS beads with sand replacement layer

leads to settlement under loading condition before adding water

to the swelling layer cause EPS beads are compressible material

and this explain why swelling and settlement are discussed

together in the test results. The studied parameters are

summarized in Table 3.

Table 3. The studied parameters

Diameter of footing (d) cm

5, 7, 10, and 12

Beads Density (

B

) kN/m

3

0.1, 0.16 and 0.2

Beads Content (B) %

0, 0.3, 0.6, 0.9, and 1.2

Normalized Replacement Thickness (t

r

/t

s

) %

0, 12.5, 20, 25 and 33

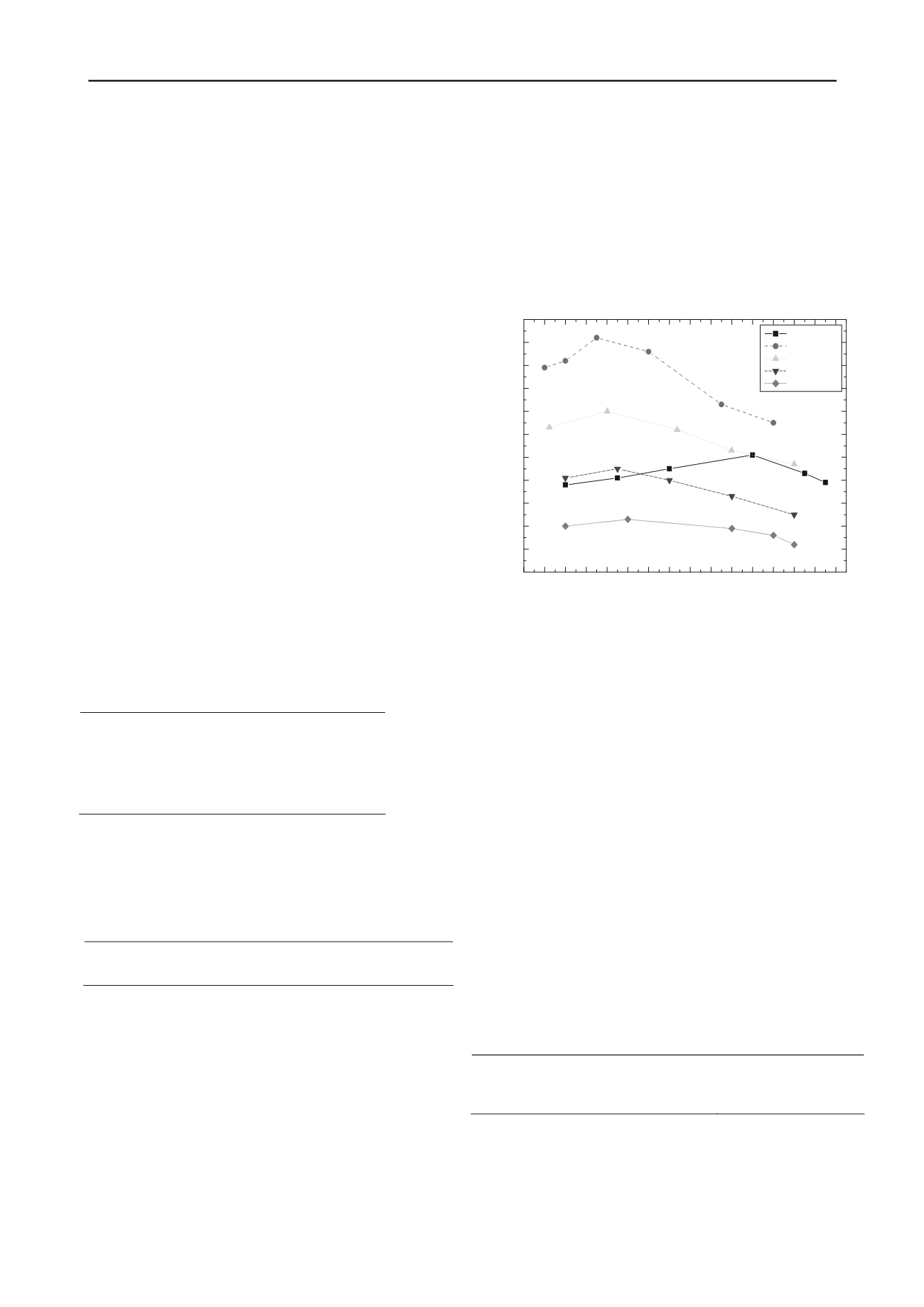

4.3 Test Results and Analysis

4.3.1 Test results presentation

Swelling and settlement on surface soil and circular footing are

presented in a set of curves with the different studied

parameters.