3158

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

and behavior associated with tire-bale use in construction,

example applications, and end-of-service-life options.

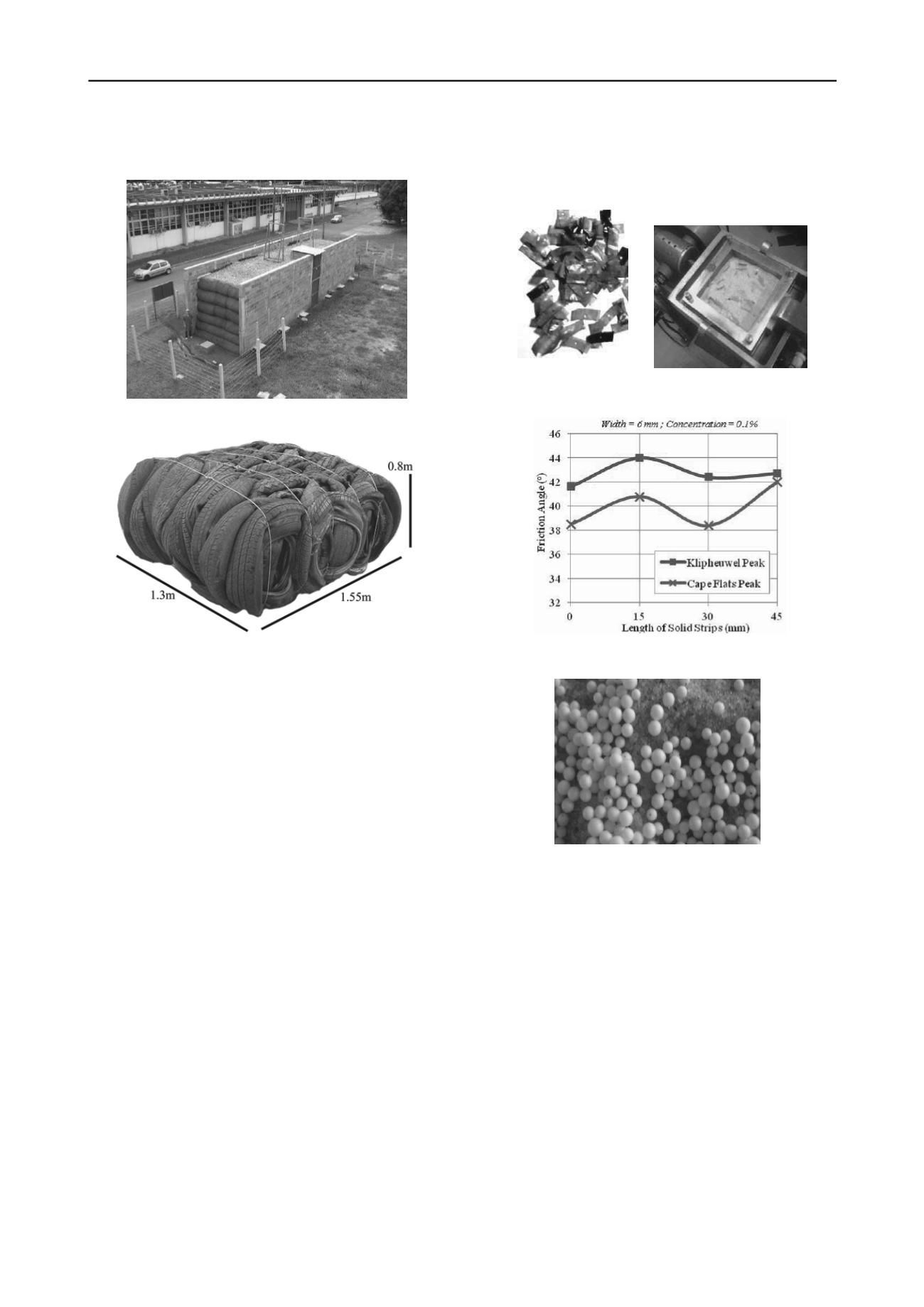

Figure 4. UnB retaining wall test facility (Figure 3 of Santos et al.).

Figure 5. A typical tyre bale (Figure 1 of Winter).

Abdelhaleem et al. considered the use of recycled rubber and

rubber-sand mixtures (RSM) as replacement soils in seismic

areas due to the increased damping capacity of RSM. They

performed site response analysis using the two-dimensional

finite element method with equivalent-linear constitutive

models for the geo-materials. Three earthquake ground motions

of comparable magnitude and varying frequency content were

applied to a deposit of sand with replacement soil and with

different configurations of RSM. A parametric study was

performed for investigating the effect of depth and thickness of

the RSM layer and of the relative magnitudes of the natural

period of the site and predominant period of earthquake on the

sand-replacement soil-RSM system.

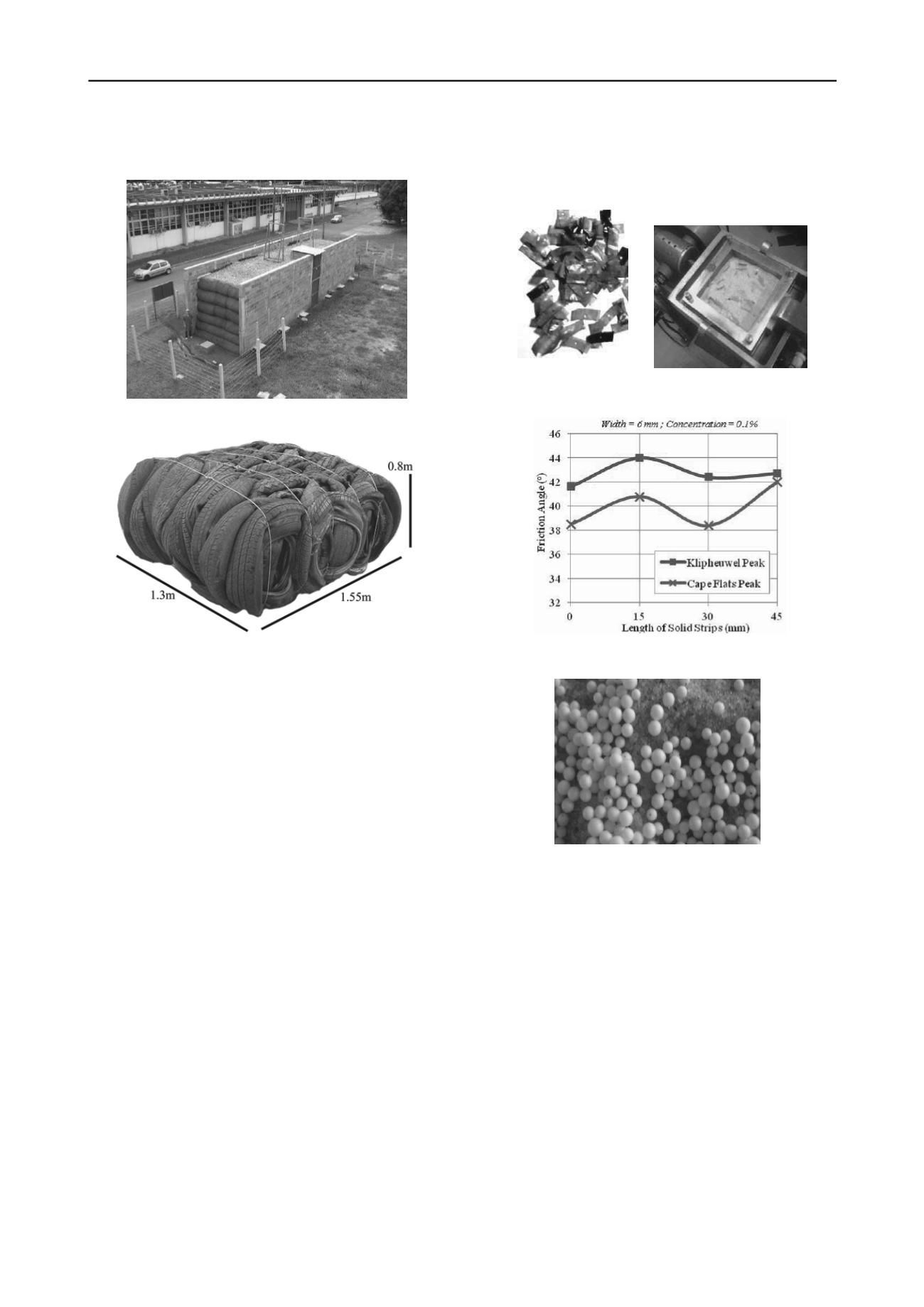

Kalumba and Chebet investigated the possibility of using

discarded polyethylene shopping bags as soil reinforcement, and

performed direct shear tests on Klipheuwel and Cape Flats

sands mixed with perforated and non-perforated polyethylene

strips of different lengths and of widths (Figure 6). Direct shear

tests were performed with sand-polyethylene mixture and it was

observed that there was an overall increase in the friction angle

due to addition of the strips and that the increase in the friction

angle depends on the length and width of the strips, perforations

present in the strip, and percent weight of the strips (see, for

example, Figure 7). Based on their results, Kalumba and Chebet

suggested that the polyethylene strips can be used to increase

the shear resistance of sandy soils.

Abdelrehman et al. performed a laboratory-scale study to

investigate the efficacy of expanded polystyrene (EPS), a

cellular polymeric material commonly used in the packaging

industry, in reducing the heave in footings placed on expansive

clay (Figure 8). They studied the compaction characteristics of

EPS of different size and bead density mixed with silica sand.

Subsequently, Abdelrehman et al. studied the response of

circular footings of different diameters resting on a layer of

sodium bentonite by replacing a part of the bentonite layer with

the EPS-sand mixture. They performed a parametric study of

the footing heave-settlement response as a function of different

proportions of EPS-sand mixture, different replacement soil-

layer thickness, footing size, and bead density. Abdelrehman et

al. found that the swelling deformation of the footing decreases

as the replacement-layer thickness increases.

Figure 6. Direct shear tests with

polyethylene chips from shopping bags (adapted from Figures 1b and 2b

of Kalumba and Chebet).

Figure 7. Friction angle of sand mixed with non-perforated polyethylene

strips versus strip length (Figure 3a of Kalumba and Chebet).

Figure 8. Expanded polystyrene (EPS) beads mixed with sand (Figure 1

of Abdelrehman et al.).

In another example of EPS recycling, Teymur et al.

compared the performance of glass foam and EPS geo-foam as

components of controlled low strength material (CLSM) often

used as compacted backfill. They performed index tests,

unconfined compression tests, and CBR tests, and found that

glass mixtures have greater unit weight and strength than those

of EPS foam mixtures. They concluded that glass foam CLSM

can be used as pavement subbase, as fill for slopes and retaining

structures, and to increase the strength and stiffness of soft clay

deposits.

Drinking water sludge (DWS) discharged during water

purification has potential use as a road infrastructure material

(Watanabe and Komini). However, decomposition of the

organic matter present in DWS decreases its shear strength

because of which it is important to determine its durability for

reuse. Watanabe and Komini collected DWS samples from

Irabaki, Japan that contains aluminum and organic matters in

the solid phase, and performed triaxial tests on the samples after

subjecting them to aluminum leaching and biodegradation.

They found that the shear strength of DWS decreases due to loss

of organic matter and aluminum (Figure 9). Watanabe and

Komini further quantified the effect of aluminum leaching and