3150

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

1

4 1

2

2

1

3

2

2

1

mmm

mm m

AS

E

AM F

d

u

3

a

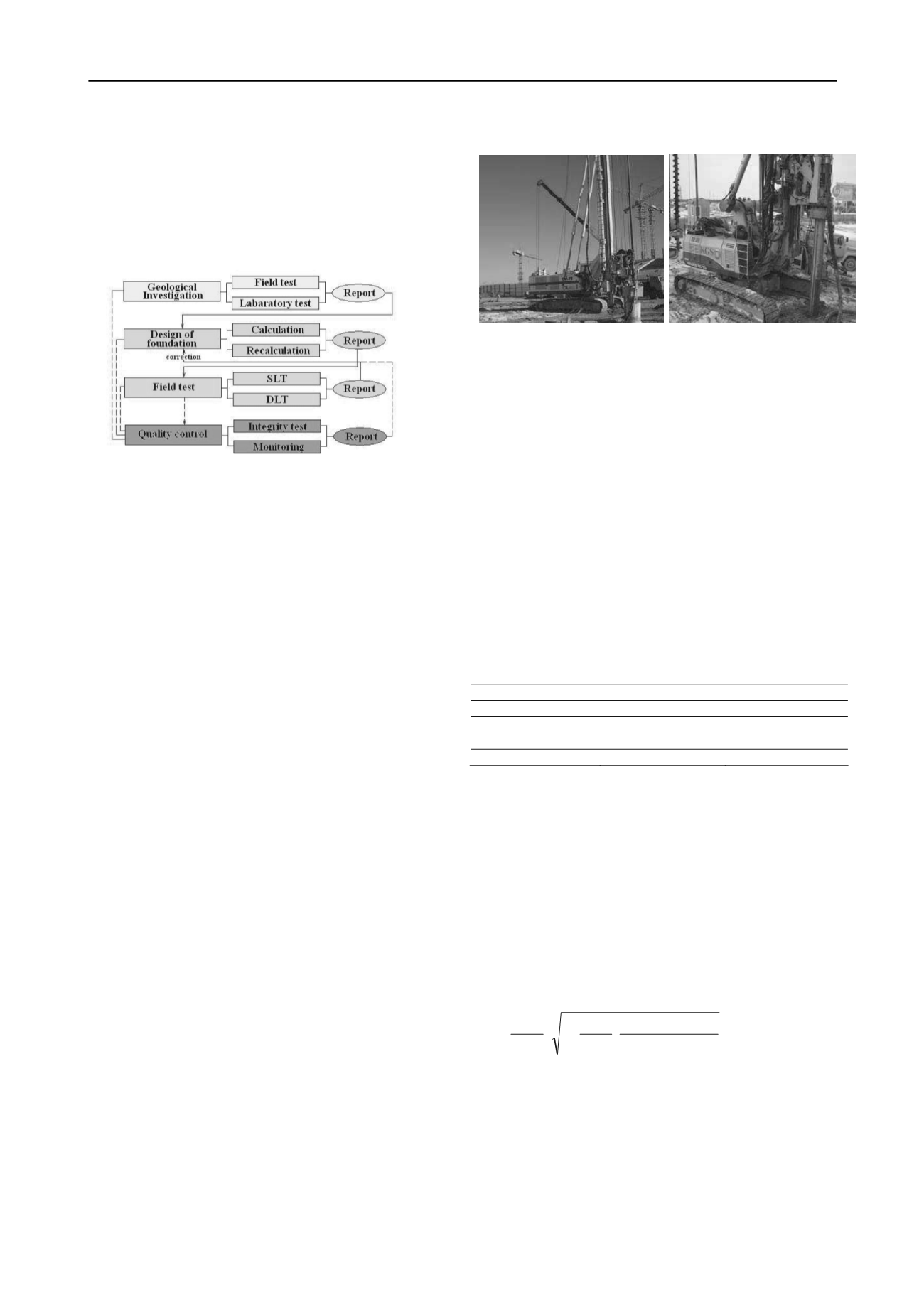

modern geoengineering requirements. The preliminary design is

performed based on the engineering and geological

investigation of construction site. Accuracy of pile design

generally depends on the accuracy of data presented in

geological report. Final pile design project is corrected after

approval by field tests. Nowadays conception of pile foundation

Figure 2.

Figure 2. Pile foundation design concept

2 FEATURES OF NEW PILE TECHNOLOGIES

The DDS technology was established by Germany Company

BAUER and undoubtedly presents practical values on

Kazakhstan construction sites. The general advantages of this

technology (comparing with traditional boring pile technology)

are: fast installation of pile, economical efficiency, low noise

during installation, absence of vibration, and high value of

bearing capacity (Sultanov G.A. 2010).

Installation of DDS pile consists of four steps, as described

below: place the boring machine to the boring place; bore the

pile hole to the design level; fill the concrete under a pressure of

300 kPa; install the steel anchor into the pile body.

The principal feature of this technology is a special boring

element. The pile hole is formed via two stages: during the

moving down of boring element, the bullet teeth loosen the soil

and the stabilizer displaces surrounding soil. During the moving

up of boring element, the secondary compaction of hole takes

place.

DDS technology allows installation of the pile up to

1200mm of diameter and 30m of length. During DDS pile

design, it is required to take into account following parameters:

diameter of pile, torque moment, indentation forces, density

(strength, compaction of soil and power of concrete pump).

A CFA pile is a type of drilled foundation in which the pile

is drilled to the final depth in one continuous process using a

continuous flight auger. The use of the continuous flight auger

rig avoids many of the problems of drilling and concreting piles

experienced when using conventional power augers. The new

CFA equipment can perform piles in most type of soils

(including sand, gravel, silt, clay, chalk and weak weathered

rock) with diameters up to 1200 mm and lengths down to 35-40

meters. So, with proper planning and design, performing

equipment and skilled personnel, high production rates and high

quality product can be achieved (Ashkey Y. 2008).

Installation of CFA pile consist of following steps: placing

the boring machine to the boring place; boring the pile hole to

the design level; removing the screw with simultaneous

concrete filling under the high pressure and replace the boring

machine, installation of steel anchor into the pile body with

preparation of pile head.

The high quality of piles is ensured by not soil extraction for

DDS and by high filling pressure for CFA.

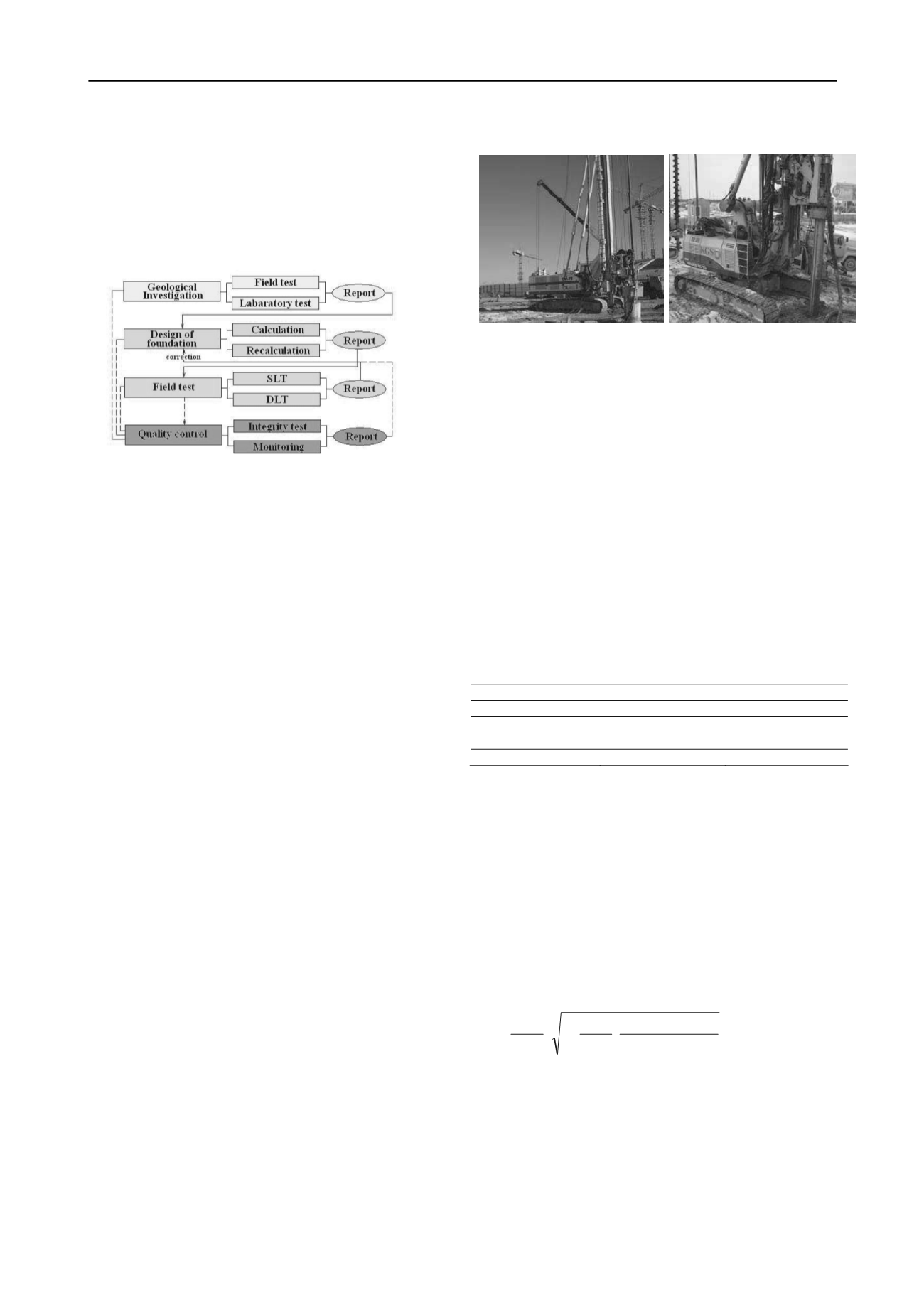

Figure 3. New pile technologies

To analyze the bearing capacities obtained by SLT, the

calculation of design bearing capacity by Kazakhstan Standards

was performed by SNIP PK 5.01.01-2002. The classically

bearing capacity is subdivided into two constituents: shaft and

tip resistance. In Kazakhstan’s Standard, the classical equation

was modified and presented by following equation:

)

(

i i

cf

cR c

d

hf

u RA

F

(1)

where γ

c

= safety factor; γ

cR

and γ

cf

= coefficients of soil

work condition under the pile tip and around the pile,

respectively.

Unfortunately, existing Kazakhstan Standards do not take

into account soil compaction under the high concrete pressure in

case of CFA technology and soil displacement without

excavation in case of DDS technology that lead to reduction of

settlement and increase in bearing capacities of pile foundation.

Therefore it had been suggested to use following coefficients of

soil working condition as presented in Table 1.

Table 1. Suggested coefficient of soil works for DDS and CFA piles

3 TESTING OF PILE FOUNDATION

Many static and dynamic load tests were performed on this

construction site. The SLT one of the more reliable field tests in

analyzing pile bearing capacity in Kazakhstan. DLT is a fast

bearing capacity analysis field test and give more or less reliable

value of pile bearing capacity.

Dynamic load test (DLT)

. For definition of the bearing

capacities of piles, it is required to use average refusal which are

obtained during redriving of the piles after their "rest". The rest

time depend on soil condition of site: for clayey soil 6 -10 days,

for sandy and gravel soils up to 3 days.

Bearing capacity of the piles is defined by following

empirical equation:

(2)

where η=factor, dependent on concrete strength of the piles;

А=cross section of tested pile; М=1 – factor, dependent on pile

driving hammer’s impact; Е

d

=effective energy of blows of the

hammer, kNm.

According to Kazakhstan Standard at least 6 piles must be

tested by DLT on each construction site.

Static Load Test (SLT)

. SLT one of the more reliable field

tests in analyzing pile bearing capacity. SLT should be carried

out for driving piles after the “rest” and for bored piles after

achievements of the concrete strength, by more than 80%.

According to requirements of Kazakhstan Standard - SNiP

RK 5.01-03-2002 (SNiP RK 2002) – ultimate value of

Type of pile

Y

cR

Y

cf

Driving Pile

1,0

1,0

Boring Pile

0,7-1,0

0,7

DDS (FDP) Pile

1,3

1,0

CFA Pile

1,0

1,0