3152

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

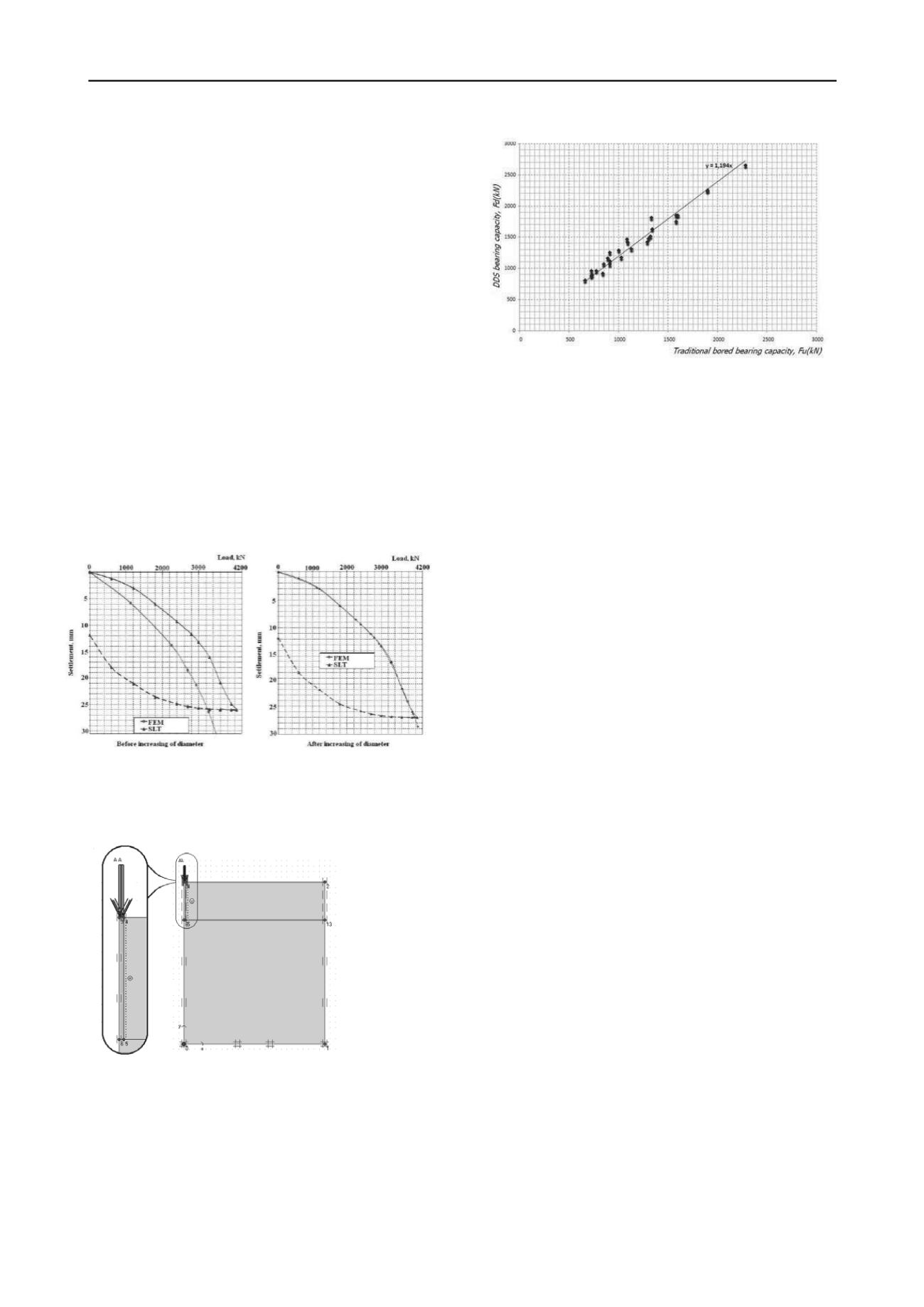

5 FEM MODELING OF BORED PILES

CFA Boring pile technology

. The FEM elasto-plastic analysis

was provided by computer program established by Prof.

Tadatsugu Tanaka. It was used the mechanical properties of soil

ground for the numerical calculation of bearing capacity and

settlement. For analyzing bearing capacity of working as

friction CFA and Casing piles were modeled and compared with

results of static load test.

Taking advantage of the axi-symmetric nature of the

problem, only a half domain of the model ground and pile were

analyzed. The soil ground and pile were discredited into four

noded quadrilateral elements. Number of nodal points are 675,

number of finite elements are 606, number of materials are 4

(1is sand with gravel, 2 is hard clay, 3 is clay, 4 is bored pile).

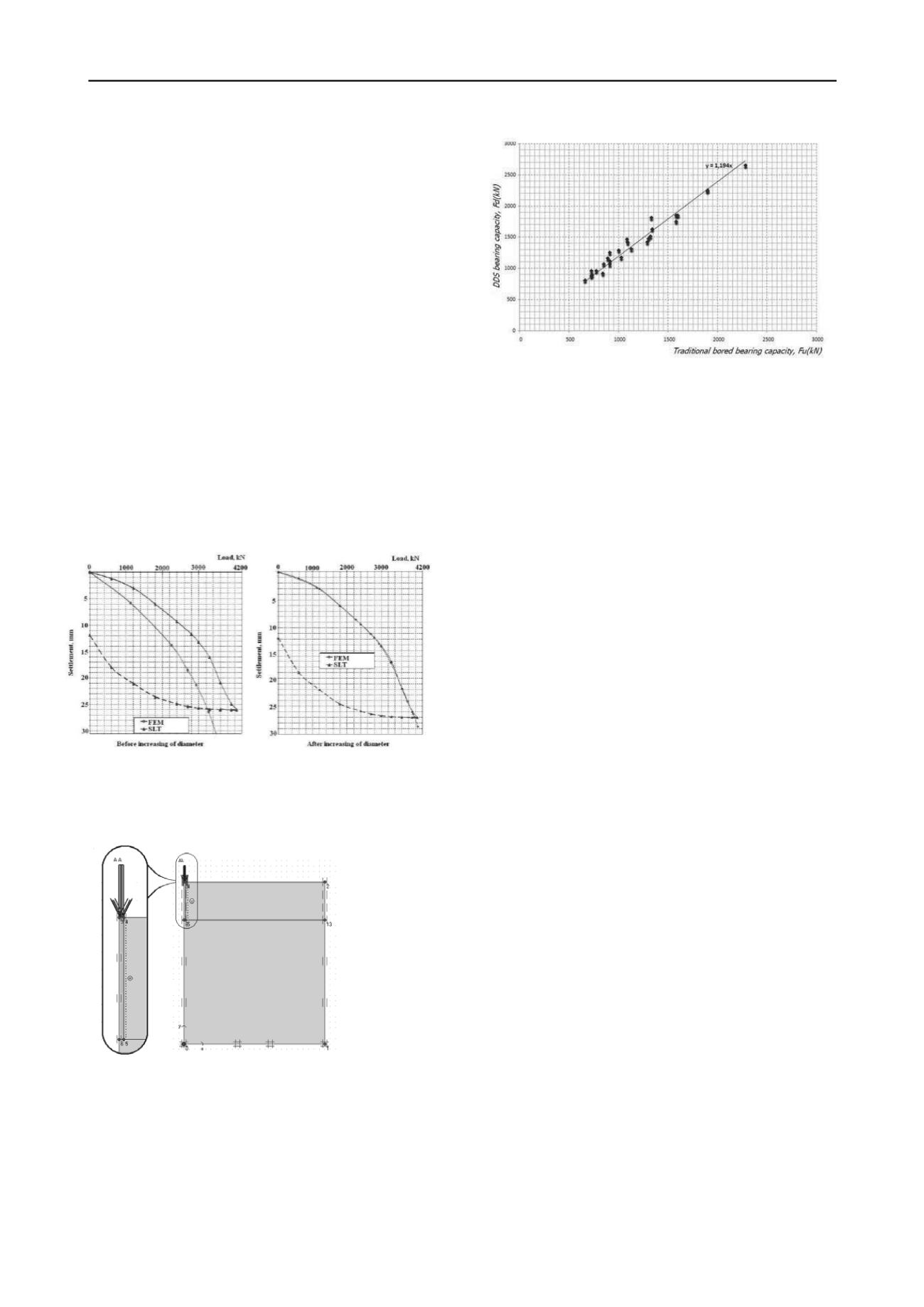

Figure 8. Comparison diagram

During CFA pile installation the question of over-

expenditure of concrete was appeared. The actual volume of

borehole was about 1.3-1.4 times more than theoretical volume

of borehole (Ashkey Y. 2008). After determination of

preliminary average radius (r+

r) increasing diameter of CFA

piles and remodeled numerical mesh FEM analysis was

repeated. It gives us increasing bearing capacity of CFA piles

respectively “load-settlement” results of field static load test and

stress and strain of soil around of single CFA pile through FEM

computer program. The results of “load-settlement” through

FEM illustrated in Figure 6.

6 CONCLUSIONS

There were presented very short descriptions of geoengineering

approach to the installation, testing and quality control of pile

foundation which using on construction sites of Kazakhstan.

This experience probable lead to the coming changes of the

concept of Kazakhstan pile foundation design.

During designing of CFA pile of buildings and structures is

need to consider volume of borehole expansion by result of

additional pressure, as well as over-expenditure of the concrete

which is depend on soil conditions and length of pile.

Significant differences between bearing capacities of DDS and

casing boring piles show incomplete usage of DDS technology

resources. The coefficient of shaft work of DDS pile was

defined and equal from 1.2 to 1.3 depending on soil condition.

PDA allows tests up to 10 piles per day, much cost effective

than SLT, and more authentic than DLT. PDA is a type of DLT

and is appropriate for any type of pile, but cannot be used to full

extent on construction sites of Kazakhstan due to absence of

Standard.

Figure 6. Results of CFA FEM analysis

DDS Boring pile technology

. The FEM modeling of DDS

pile was made in Plaxis 2D computer program (Figure 7).

Pile integrity test is in the process of gaining official

acceptance in Kazakhstan. PIT is a non-destructive method

allowing make quality control of pile body whereupon of pile

installation and even after many years of building exploitation.

Geomonitoring for foundation settlement is indirect control of

pile quality evaluation method and has become more relevant,

especially for high-rise building construction.

Application of advanced technologies of pile foundations

installation led to a significant economical efficiency.

According to tests results, the piles installed by the above

technologies showed high values of bearing capacity, which led

to a decrease of pile length by 10 to 20% and increase

economical efficiency by 20 to 30%.

7 REFERENCES

Zhussupbekov A.Zh. and Lukpanov R.E. 2012, Geotechnical issues of

megaprojects on problematical soil in Kazakhstan

, Volume of

Abstracts of ACEM`12,

Seoul, Korea, 127.

Sultanov G.A., Zhussupbekov A.Zh. Lukpanov R.E. and Enkebaev S.B.

2010, Research of Interaction between Displacement Pile and Soil

Basement.

Proc. of Kaz-Kor joint geotechnical seminar

. Astana,

Kazakhstan, 84-91.

Figure 7. FEM modeling of DDS

The comparison diagram of bearing capacities of DDS and

traditional bored piles by Plaxis is presented in Figure 8

(Expressed by k=F

d

/F

u

, where F

d

– DDS bearing capacity, F

u

–

traditional bored pile bearing capacity). The points on diagram

are lying above the diagonal line; it means that the values of

DDS bearing capacity are exceeding traditional bored piles [2].

Ashkey Y. 2008, Interaction of CFA bored piles with soil condition in

Astana.

A dissertation submitted in partial fulfillment of the

requirements for the PhD degree.

Astana, Kazakhstan.

SNiP RK 5.01-03-2002 “Pile foundation”.

Zhussupbekov A.Zh. and Lukpanov R.E. 2012, Geotechnical issues of

megaprojects on problematical soil in Kazakhstan

, Proc. of 3

rd

ICNDSMGE-ZM 2012,

Near East University, Nicosia, TRNC,

67-75.

After some transformation it was got FEM coefficient of

DDS pile works, which vary from 1.23 – 1.35 depends on type

of soil (See Table 1).