3157

Technical Committee 307 /

Comité technique 307

case approach with proper investigations for making decisions

regarding the suitability of fly ash as a construction material.

Kikuchi and Mizutani proposed the use of granulated blast

furnace slag (GBFS) as an alternative construction material for

port structures because GBFS can reduce liquefaction potential

and earth pressure when used as a backfill material for quay

walls. The inherent ability of GBFS to solidify upon contact

with seawater was explored and methods were proposed for its

standardized application in the field. As GBFS solidification is a

lengthy process and often the solidification is not uniform,

Kikuchi and Mizutani proposed the use of powdered blast

furnace slag (PBFS) in conjunction with prior homogeneous

mixing treatment (PHMT) to accelerate the GBFS solidification

process. In their experimental investigation, Kikuchi and

Mizutani considered several issues, e.g., material separation

after construction due to water flow, solidification of GBFS

underground with flowing water, and the effect of the change in

pore fluid chemistry due to a change from sea to fresh water on

GBFS solidification, in determining the most appropriate

mixture of GBFS and PBFS for accelerating the GBFS

solidification. The authors found that PHMT treated GBFS-

PBFS mixture is effective in reducing the amount of material

separation in the GBFS-PBFS mixture and produced sufficient

unconfined compression strength after about 2 months of curing

in the seawater because of which it can be used to prevent

liquefaction.

Nawagamuwa et al. investigated the properties of waste

copper slag for use in vertical sand drains and sand piles as a

substitute for sand. Geotechnical properties such as particle size

distribution, hydraulic conductivity, shear strength, and stiffness

were studied for the sand-sized waste copper slag particles

mixed with poorly graded sand. It was observed that the particle

size distribution, shear strength and hydraulic conductivity were

not significantly affected due to the addition of the slag.

However, the stiffness of the slag-sand mixture increased

significantly. Based on the study, Nawagamuwa et al. concluded

that waste copper slag can be safely and effectively used as a

replacement for sand in vertical drains.

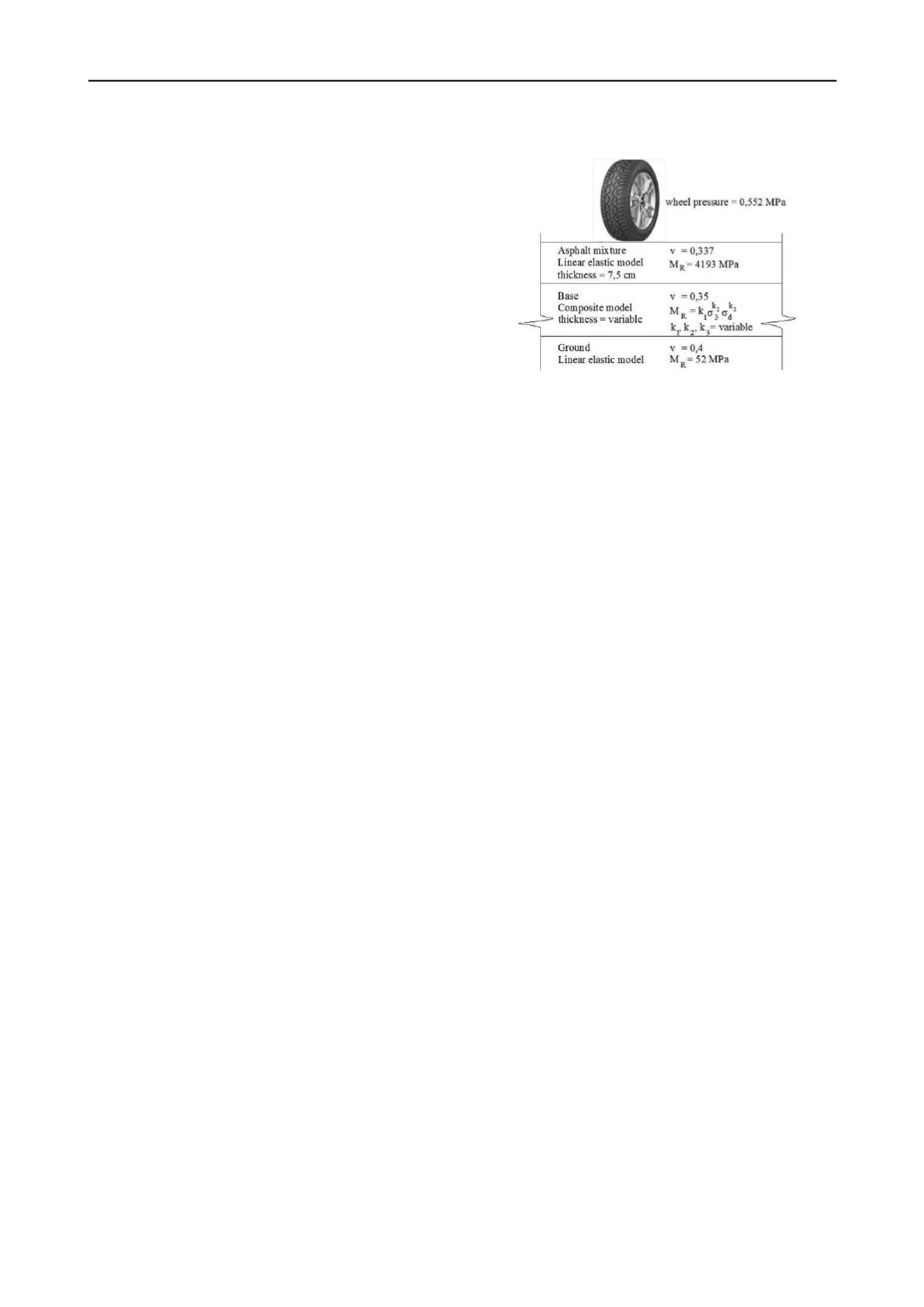

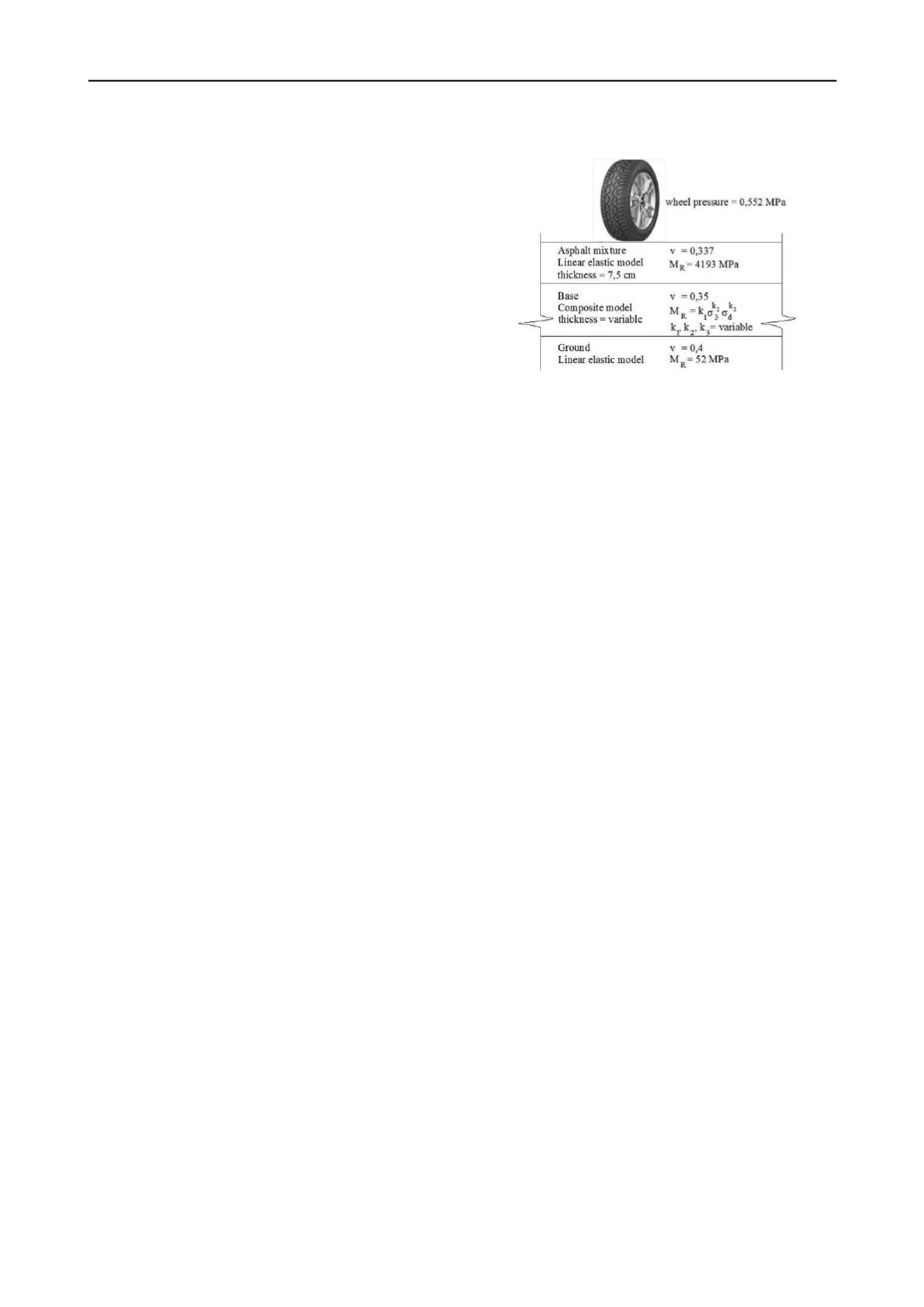

Vizcarra et al. (2013) investigated the applicability of

municipal solid waste (MSW) incineration ash mixed with non-

lateritic clay in pavement base layers. Chemical, physical,

index, and mechanical tests were performed on the ash-soil

mixture with 20% and 40% ash content, and the mechanistic-

empirical design (Figure 3) for a typical pavement structure

were carried out. The mechanical tests included modified

Proctor test, resilient modulus test, and permanent deformation

test. The addition of 20% fly ash to the non-lateritic clay soil

improved the mechanical behavior and reduced the expansion of

the clay. The fly ash mixed soil had a mechanical behavior

compatible with the requirements for a low traffic volume.

Edil also focused on pavement geotechnics and provided an

overview of different recycled waste products used in pavement

construction. He discussed about the rapid characterization of

industrial wastes like fly ash and bottom ash, and construction

and demolition wastes (CDW) like recycled asphalt pavement

and concrete aggregates with respect to their physical

characteristics, geomechanical behavior, durability, material

control, and environmental impact.

In another study related to pavements, Cameron et al.

proposed the use of recycled concrete aggregates (RCA)

blended with recycled clay masonry (RCM), obtained after

demolition, in unbound granular pavements. The CDW were

obtained from two local producers in South Australia, and

conventional classification tests for soils and aggregates, Los

Angeles abrasion test, Micro-Deval test, falling head

permeability test, drying shrinkage test, undrained triaxial and

repeated loading triaxial tests, and permanent strain rate

modeling were performed. The test results were compared with

the specifications from road authorities both within and outside

Australia, and the RCA products were classified as Class 1 or

base and the blended products as Class 2 or subbase materials.

Figure 3. Pavement structure adopted in mechanistic-empirical analysis

(Figure 1 of Vizcarra et al.).

Farias et al. also studied the feasibility of using CDW in

paving of a shopping-center site in Recife, Pernambuco, Brazil.

They performed a series of physical, chemical and mechanical

tests with mixtures of different proportions of CDW obtained

from the site and in situ excavated soil, and concluded that the

recycled residues of civil construction (RRCC) alone and RRCC

mixed with soil meet all the criteria of the local standard NBR

15.116:2004. Farias et al. (2013) also performed an economic

analysis of different construction alternatives with the RRCC,

which is described in section 3.5.

The study by Santos et al. also involves CDW. They

presented a laboratory-scale experimental investigation on the

performance of instrumented wrapped-faced retaining walls

constructed using recycled construction and demolition wastes

(RCDW) consisting of soil, bricks, and small particles of

concrete. CDW is abundantly available in Brazil and

approximately 70% by mass of municipal solid waste consist of

CDW. CDW was found to have excellent mechanical and

chemical properties for use as a back-fill material in

geosynthetics reinforced walls. Consequently, two 3.6-m high,

wrapped-faced retaining walls with facing batter angle of 13

were constructed at the University of Brasilia (UnB) Retaining

Walls Test Facility. One retaining wall was constructed with

geogrid and the other with geotextile with identical

reinforcement lengths and spacings of 2.52 m and 0.6 m,

respectively, using RCDW as the compacted backfill (Figure 4).

The walls were instrumented along their central sections to

measure strains, displacements, and earth pressures. The walls

performed well during and after construction with the maximum

horizontal displacement at the wall face being 150 mm. The

only downside was the creation of uneven surfaces near the face

due the presence of coarse particles. The use of a selected

RCDW near the face for better aesthetic appeal was

recommended.

Vaníček et al. presented an example of waste recycling in

which a new construction material consisting of brick, fiber and

concrete was used to reinforce dykes for flood protection and

erosion control.

Winter discussed the use of lightweight tire bails (Figure 5)

as a potential alternative for pavement foundation on soft soils.

Tire bales comprise of 100 to 115 tires of light-goods vehicles

and cars compressed into a lightweight block with a mass of

about 800 kg and density of approximately 0.5 Mg/m

3

. The

bales measure approximately 1.3 m

1.55 m

0.8 m and are

secured by five galvanized steel tie-wires running around the

length and depth of the bale. The key advantage of tire bales is

their modular nature which leads to potential savings in plant,

labor, and time. These bales have been used in pavement

constructions, slope protection, river bank erosion control, and

lightweight embankment constructions. Winter described the

different construction techniques and provided information

regarding the measurement of properties, engineering properties