3166

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Group (2) - (T

p

> T

site

)

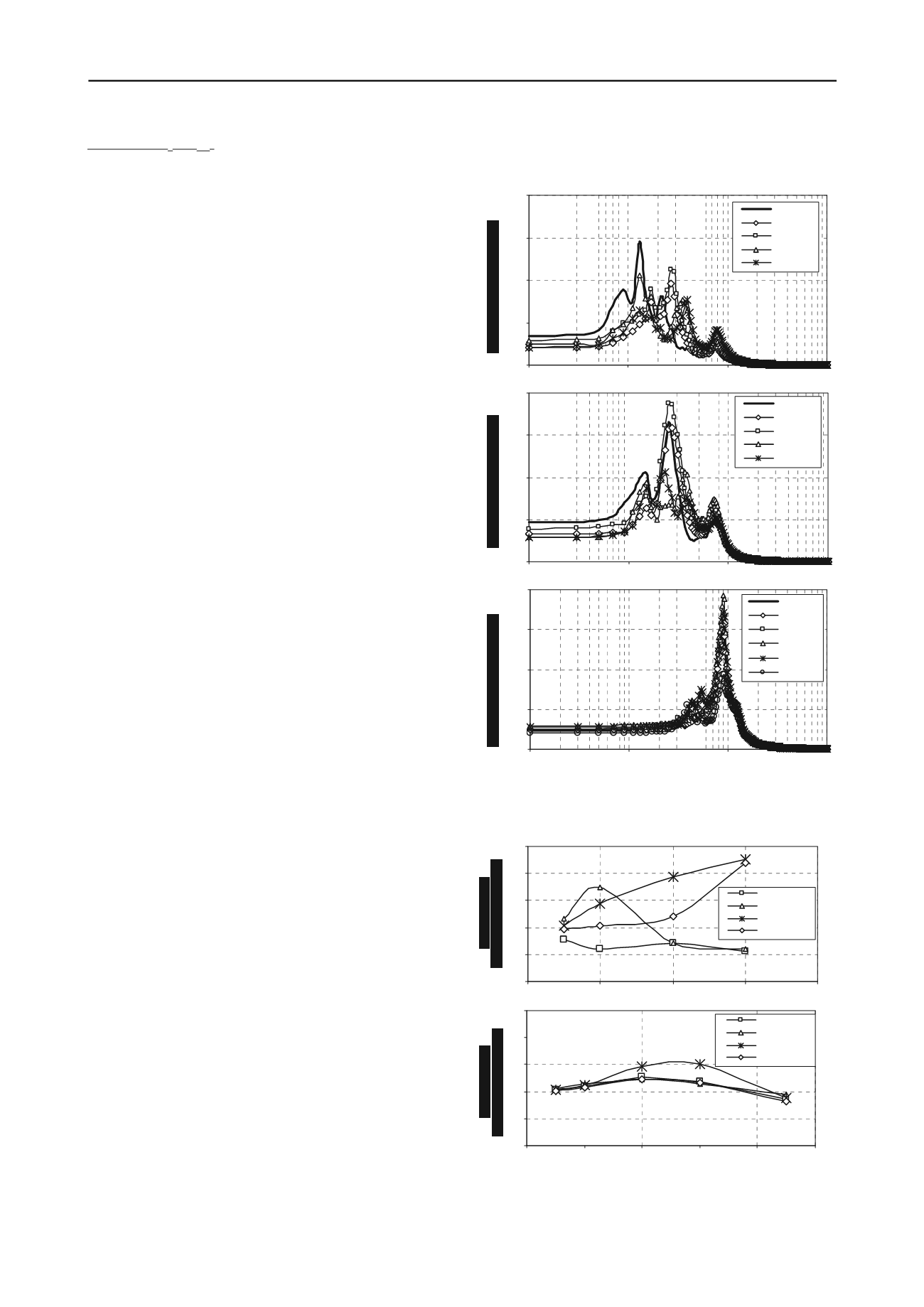

Increasing the thickness of the RSM layer from 1m to 4m

caused increasing in the maximum spectral acceleration

compared to the base line case. Increasing the thickness of the

RSM layer from 4m to 6m resulted in a reduction in the

maximum spectral acceleration decreased but still higher than

the maximum spectral acceleration in the base line case.

Increasing the RSM thickness to 9m resulted in reduction in the

maximum spectral acceleration equals to 38% compared to the

baseline case. Increasing the thickness of the RSM layer from

1m to 4m caused increasing in the spectral acceleration at low

and high periods compared to the base line case (Figure 7).

However, further increase in the thickness up to 9m resulted in a

reduction in the amplification factor below the baseline case.

6 CONCLUSIONS

The following main points may be concluded based on the

analyses presented herein:

o

The effect of using RSM layer is dependant on the site natural

period and the frequency content of the ground motion, while

the effective configuration of the RSM layer is subject to the

natural period of the intended structure.

o

Placing a layer of RSM resulted in increasing the site natural

period causing damping of spectral accelerations at low

periods and amplification of spectral accelerations at higher

periods compared to the baseline case.

o

The deeper the RSM layer, the larger the shift in site natural

period resulting in more effective damping and lower

response spectrum at ground surface for a wider range of

periods. Thus, the higher the natural period of the structure,

the deeper the sand/rubber layer needed to achieve damping.

o

For the same excavation depth, using a thin layer of RSM at

the bottom of the excavation is more effective in damping the

spectral accelerations at ground surface than using a thick

layer of RSM.

o

Settlements and creep in RSM layer should be studied in case

of large thickness.

o

Further investigation is needed to confirm the observation

through physical and numerical modeling for earthquakes of

different magnitude, amplitude, and frequency content.

o

Soil structure interaction needs to be further investigated to

examine the effect of the overlaying structure on the response.

7 REFERENCES

Anastasiadis, A., Senetakis, K., Pitilakis, K., Gargala, C., and Karakasi,

I. (2012)

“Dynamic Behavior of Sand/Rubber Mixtures. Part I:

Effect of Rubber Content and Duration of Confinement on Small-

Strain Shear Modulus and Damping Rat

io,” J. ASTM Int’l., 9

(2).

Bray, J. D., and Rodriguez-Marek, A. (1997). "Geotechnical Site

Categories." Proceedings First PEERPG&E Workshop on Seismic

Reliability of Utility Lifelines, San Francisco, CA.

Edil, T.B. and Bossc

her, P.J. (1994). “Engineering P

roperties of Tire

Chips and Soil M

ixtures,” Geotech

. Testing J., ASTM 17(4), pp.

453-464.

Feng, Z., and Sutter K.G. (2000). “Dynamic

Properties of Granulated

Rubber/Sand Mixtures,”

Geotech. Testing J., ASTM, Vol. 23, No.

3, September, pp. 338-344.

Ghazavi, M., (2004). “Shear

Strength Characteristics of Sand-Mixed

with Granular R

ubber,” Geotechnical and Geological Engineering,

Vol. 22, pp. 401-416.

Mavroulidou, M., Etan, O., and Suntharalingam, M. (2009).

“Mechanical

Properties of Granulated Tyre Rubber-Sand M

ixture,”

Proceedings of the 11th International Conference on Environmental

Science and Technology, Crete, Greece, 3-5 September.

Senetakis, K., Anastasiadis, A., Pitilakis, K., and Souli, A. (2012).

“Dynamic

Behavior of Sand/Rubber Mixtures. Part II: Effect of

Rubber Content on G/Go-g-DT Curves and Volumetric Threshold

Strain,” J. ASTM Int’l., 9(2).

Xu, X., Lo, S.H., Tsang, H.H., and Sheikh, M.N. (2009). “ Earthquake

Protection by Tire-

Soil Mixtures: Numerical Study,” New Zealand

Society for Earthquake Engineering Conference Proceedings,

Christchurch, New Zealand, April.

Zornberg, J.G., Cabral, A.R., and Viratj

andr, C. (2004). “Behaviour of

Tire Shred

–

Sand M

ixtures,” Canadian

Geotech. J., Vol. 41, April,

pp. 227-241.

( a) Lyt el Creek,19 70

0.0

0.5

1.0

1.5

2.0

2.5

0

2

4

6

8

RSM thickness ( m)

T = 0.1sec

T = 0.25 sec

T = 0.50 sec

T = 1.0 sec

( b) M ammot h Lake, 19 8 0

0.0

0.5

1.0

1.5

2.0

2.5

0

2

4

6

8

10

RSM thickness ( m)

T =0.1sec

T =0.25 sec

T =0.50 sec

T =1.0 sec

Figure 7. Effect of RSM thickness on spectral acceleration

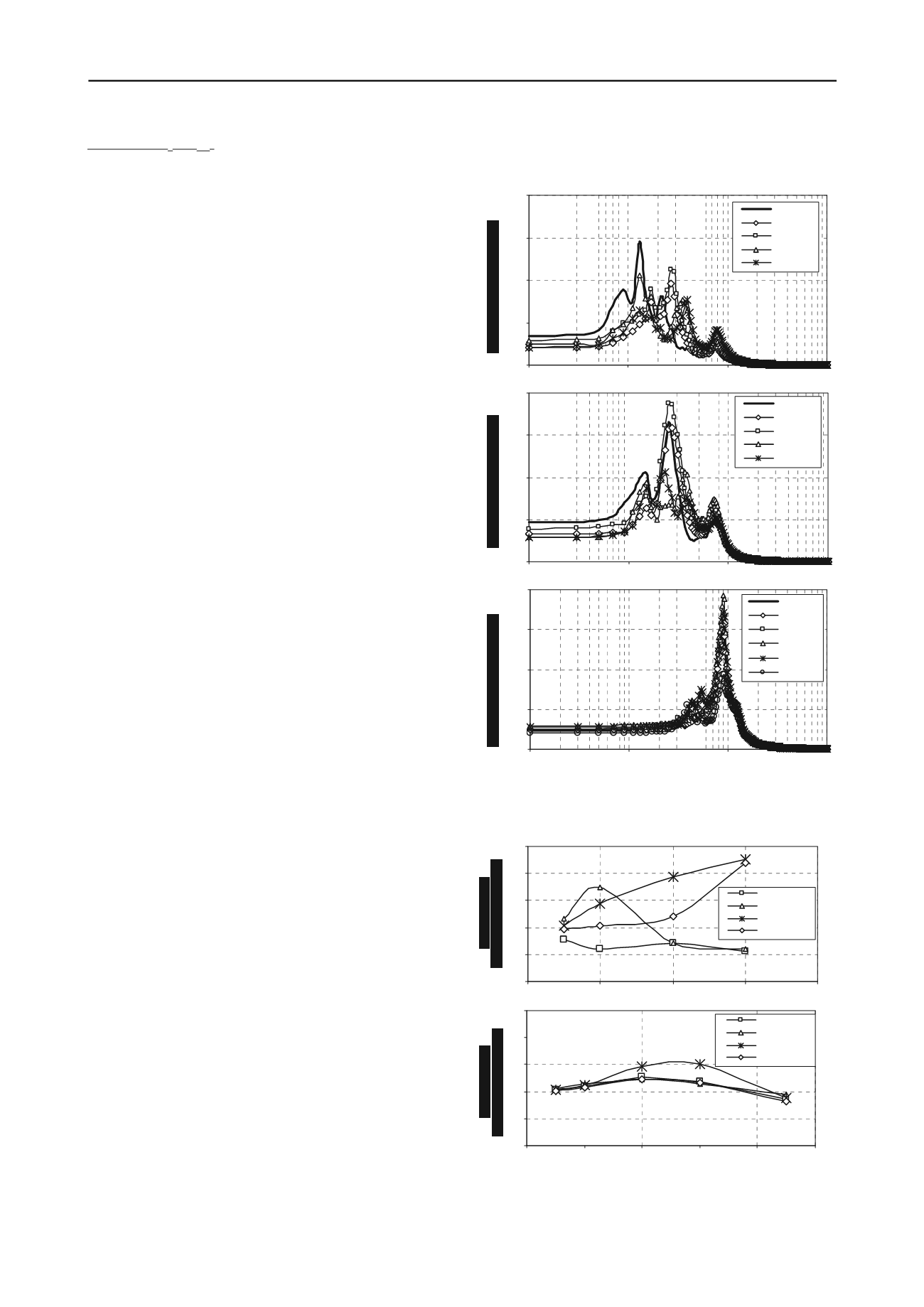

( a) Lyt el Creek

0

0.02

0.04

0.06

0.08

0.01

0.1

1

10

Period ( sec)

Pure sand

h =1m

h =2m

h =4m

h =6m

( b) San Francisco

0.00

0.02

0.04

0.06

0.08

0.01

0.1

1

10

Period ( sec)

Pure sand

h = 1m

h = 2m

h = 4m

h = 6m

( c) M ammot h Lake

0.00

0.02

0.04

0.06

0.08

0.01

0.1

1

10

Period ( sec)

Pure sand

h = 1m

h=2m

h=4m

h=6m

h=9m

Figure 6. Response spectra of surface layer for variable RSM thickness

having depth (Y = 1m) to top of RSM layer

Depth (Y) = 2.0 m

Depth (Y) = 2.0 m