3151

Technical Committee 301 /

Comité technique 301

settlement of the tested pile is depending on category of

construction and is equal 16 or 24 mm. The last argument

shows conditional character of SLT method.

According to Kazakhstan Standard 1% of constructed piles

on construction site must be tested by SLT, but at least 2 SLTs

in a site must be done.

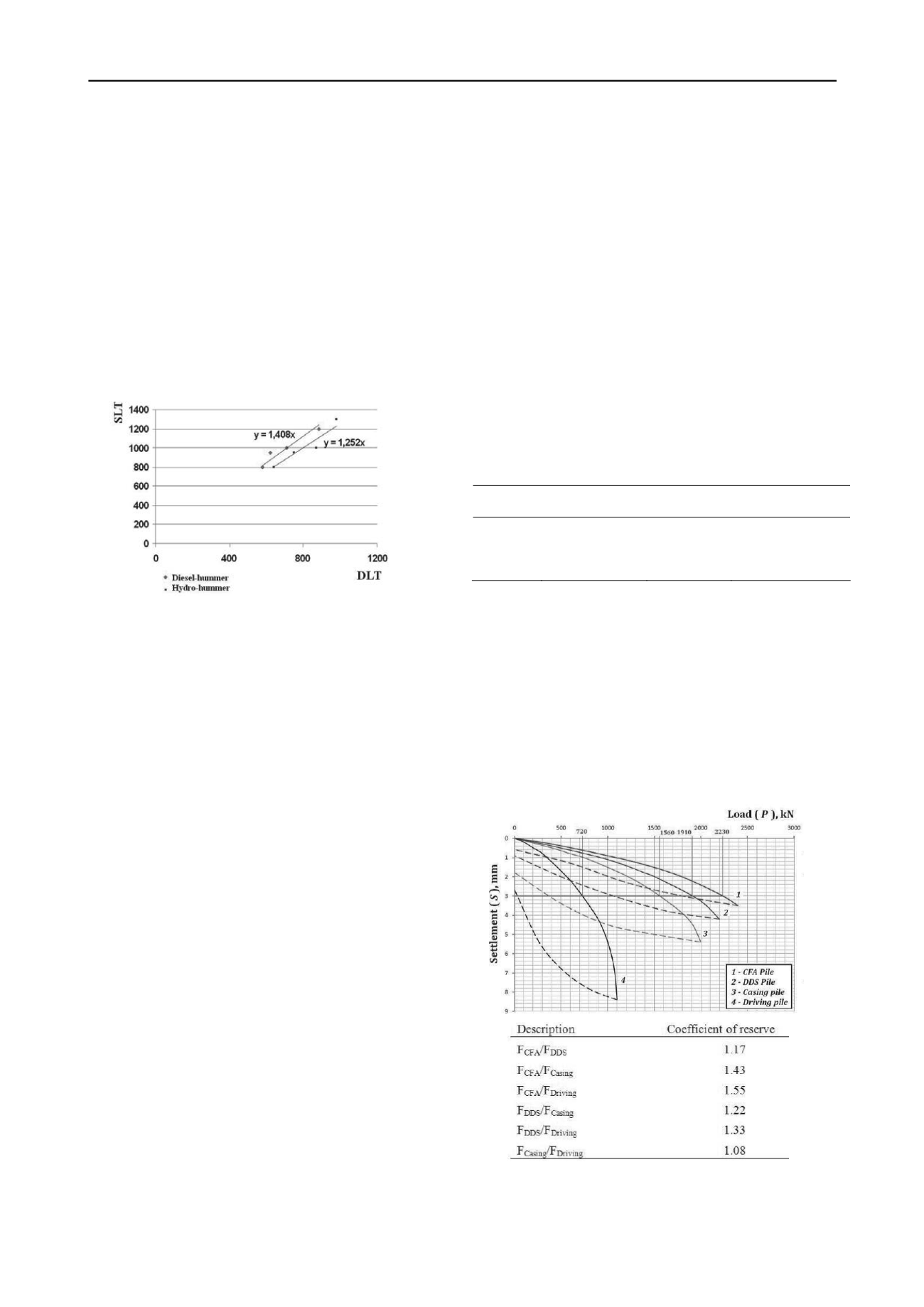

Comparison of SLT and DLT

.

SLT and DLT both are

practiced in Kazakhstan construction. According to experience

on construction sites of Astana, some difference exists between

SLT and DLT results. Moreover, results of bearing capacity of

pile depend on type of hammer. Thus, DLT results obtained by

using hydro-hammer are more approximate to the SLT results,

namely more reliable than results obtained by using diesel

hammer (Ashkey Y. 2008). The safety factor as defined by

comparative analysis of many DLT and SLT data is presented in

Figure 4.

Figure 4. Comparison SLT and DLT

Alternative Load Test Method

. From aforementioned it

follows that SLT and DLT both have disadvantages. SLT

required a lot of time, works and cost. Prescribed by Standard

quantity of required SLT is not enough to adequately realize soil

condition of construction site (2 SLT for 200 piles only). DLT

is much faster but is not so reliable and is applicable to driving

piles only.

Alternative load test method which precluded disadvantages

of both SLT and DLT was used on this construction site – Pile

Dynamic Analysis Method (PDA). PDA allows tests up to 10

piles per day and much cost effective than SLT. The

comparison of SLT, DLT and PDA approved superiority of Pile

Dynamic Analysis Method.

The O-cell bi-directional test of bored piles was firstly used

on construction site of Astana. The general advantages of this

method as compared with SLT and DLT are follows: no anchor

piles, no external reaction system, no heavy transport is

required, only half the stresses applied to the concrete,

significant cost saving as loads increase.

Quality control of pile foundation.

Pile integrity test is one of

the non-destructive methods of pile quality control. This method

allows analyzing integrity control for all existing types of piles

(boring, injection, driving and so on). PIT is base on wave

propagation theory in rigid body and is concerned with one of

the modern quality control methods used world-wide. PIT

allows detecting pile defects: approximate pile length,

expansion and narrowing of pile cross section, modification of

soil layers, heterogeneity of pile material, cracks in cross

section of pile, extrinsic material in pile body.

Advantages of PIT are as follows: portable device is easy to

carry. One operator will be able to test over 100 piles per day,

depends on site condition, pile head preparation and approach to

the pile; minimum influence to the construction work on the

site; significant defects may be detected in the beginning of the

construction. PIT has some limitations: reflection of the bottom

of pile sometimes has errors depending on soil condition; little

deflection (less than 5 %) of pile cross section cannot be

identified.

According to Kazakhstan Standard requirements it is

necessary to test 60% of boring piles and 50% of driving piles.

Geomonitoring.

Geomonitoring for foundation settlement is

one of the quality control methods that can be carried out during

and after construction in exploitation period. Monitoring is

indirect control of pile installation evaluation.

The principle of this method is monitoring the settlement of

special marks which are installed to interested points of

construction. Monitoring starts from the beginning of

construction and allows revealing defects of foundation

installation.

4 COMPARISON OF SLT RESULTS

SLT of different types of pile was performed with a view to

compare bearing capacity of traditional (namely, boring casing

pile and driving pile) (Zhussupbekov A.Zh. 2012).

All the piles were designed to the criteria of 2200kN bearing

capacity. Designed parameters of piles (length and cross

section) by Kazakhstan Standards are presented in Table 2.

Table 2. Designed pile characteristic

Type of

pile

Required

quantity, e.a.

Length of

pile, m

Diameter or cross

section, m

CFA

1

10

0.5

DDS

1

10

0.5

Casing

1

10

0.5

Driving

2

12

0.3 x 0.3

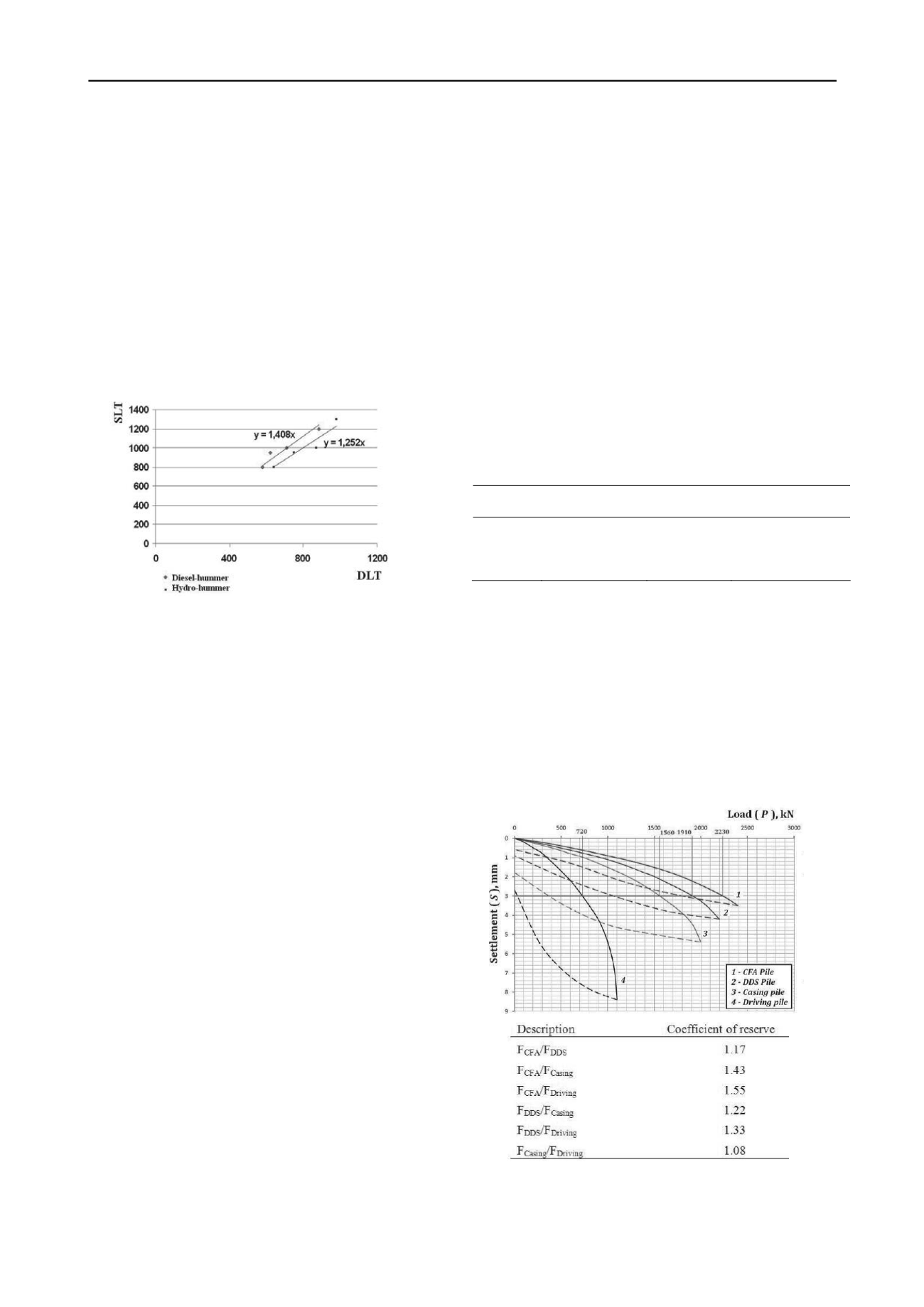

Results of comparison are presenting in Figure 5.

All of these coefficients show incapacity of accurate design

of modern pile technology by out-of date Standards, otherwise

this coefficients tending to 1. The results of SLT showed

entirely expected regularity. CFA piles showed highest bearing

capacity as long as during CFA pile installation it was expended

much more concrete (in 2 times) than during casing pile

installation. This factor was not considered during design;

therefore coefficient equal 1.43. DDS pile approved effluence of

compacted soil; therefore coefficient equal 1.22 (DDS versus

casing). Differences between driving and casing pile neglected

small, the reason of differences is empirical coefficients

required by Standards.

Figure 5. Bearing capacity comparison of different piles