2692

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

2 EXPERIMENTAL BACKGROUND

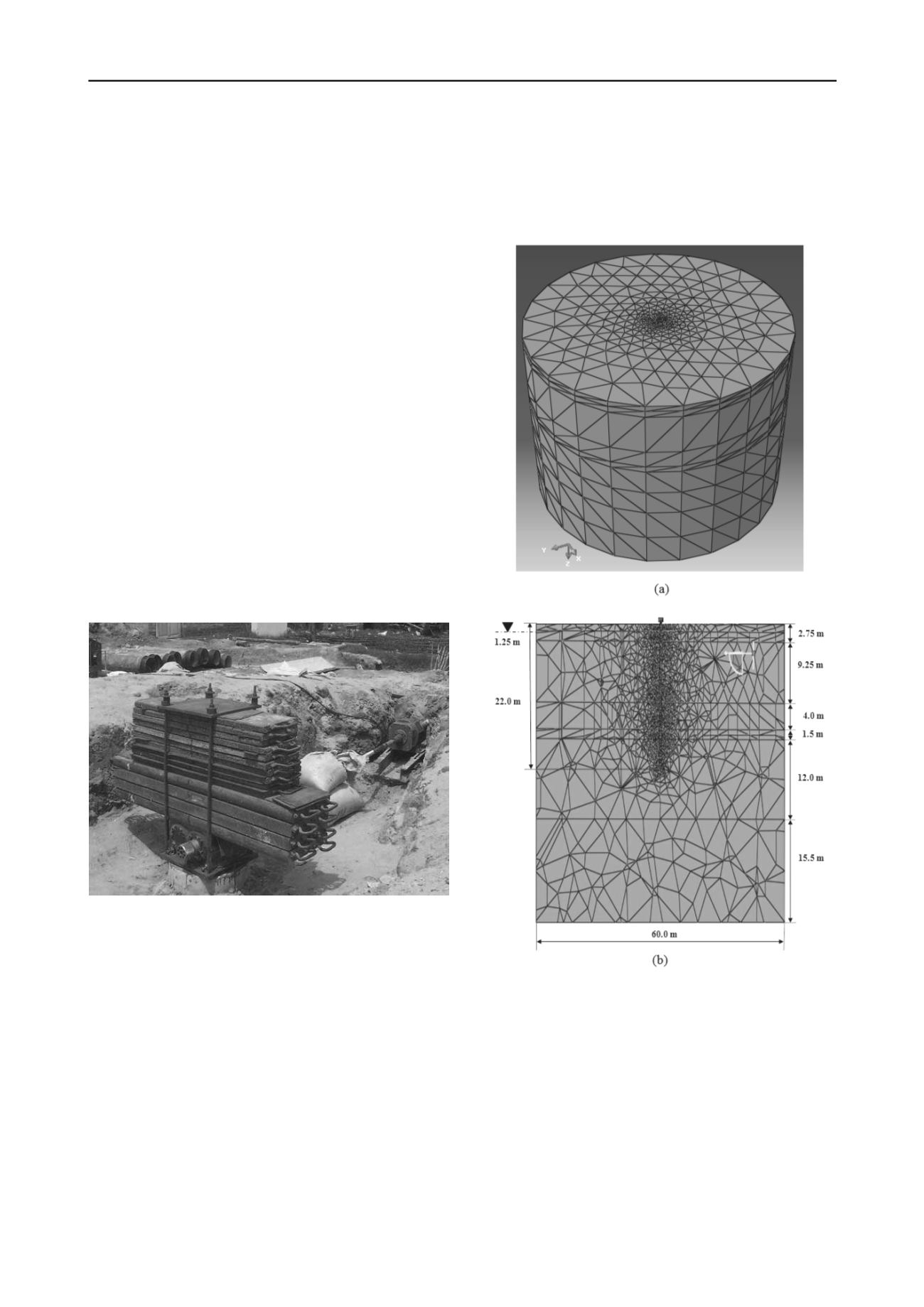

The vertical vibration tests on the full-scale single pile were

conducted at I.I.T. Kharagpur Extension Centre, Block No. HC,

Plot. 7, Sector - III, Salt Lake City, Kolkata, India (Manna and

Baidya, 2009). In the field three bore holes were made and soil

samples were collected. The depth of exploration below ground

level was 30.45 m. Disturbed representative soil samples and

undisturbed soil samples were collected from the field. During

boring ground water was encountered in all the three boreholes

and it was found that the position of standing water table was at

1.25 m below the ground level. Standard penetration tests (SPT)

were carried out in the field and the SPT -

N

value was

determined at different depths of the soil strata. Based on

different laboratory observations and field test results the site

soil was divided into six different layers. The RCC piles were

constructed at site using cast in situ technique. The diameter and

length of the pile were 0.45 m and 22 m respectively. Forced

vibration tests were conducted on the piles in vertical direction.

The mechanical oscillator (Lazan type) was used to induce

unidirectional vibrations on pile foundation. The mechanical

oscillator was connected by means of a flexible shaft with a

motor and its speed was controlled by a speed control unit. The

vibration measuring equipment consisted of a piezoelectric

acceleration pickup and the associated vibration meter. The

complete dynamic test set up is shown in Figure. 1. The

amplitudes were measured at different frequencies for each

eccentric setting. Tests were conducted for four different

exciting moments (0.278, 0.366, 0.45, and 0.529 Nm) under

different static loads (8 kN and 10 kN).

Figure. 1 Complete setup of vertical vibration test on full-scale pile

3 THREE DIMENSIONAL FINITE ELEMENT

MODELLING

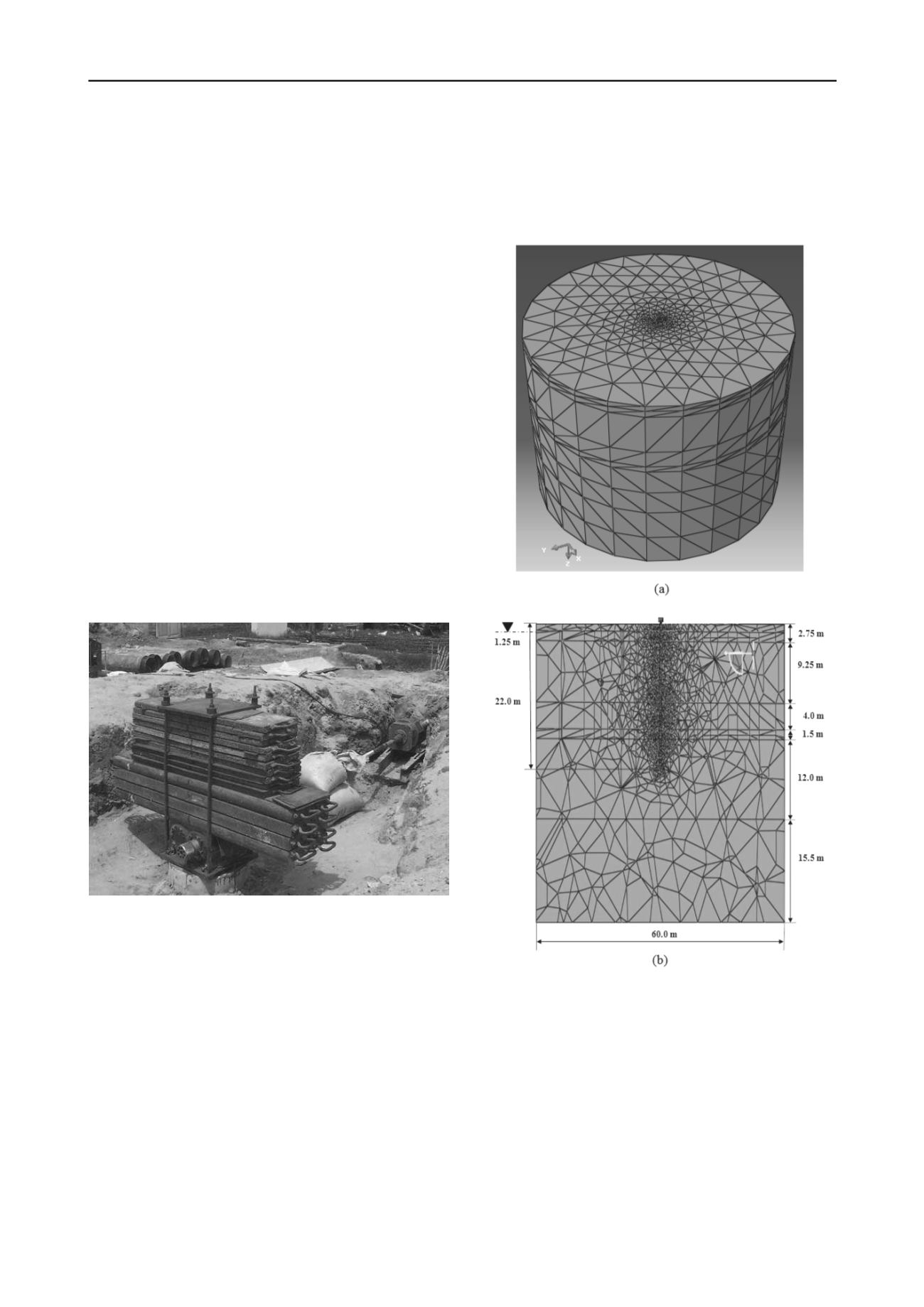

A 3-D FE model was developed to study the nonlinear soil-pile

interaction using the finite element software, ABAQUS/CAE

6.11 (2010). A harmonic vibration load was applied i.e., rotating

mass type machine at the top of a 0.45 m diameter single pile

having 22 m length. Both the pile and soil mass were meshed

using tetrahedral solid elements (10 nodded) where elements

were more closely spaced near the pile compared to the outer

region shown in Figure. 2(a). Boundary conditions were applied

to those regions of the model where the displacements and/or

rotations were known. Bottom soil boundary nodes were

considered as fixed against displacements and rotations at all

directions. At the side soil boundary, nodes displacement and

rotation were allowed only in vertical Z direction.

The soil-pile interaction was modelled using surface-to-

surface contact algorithm, where relative movement between

soil and pile was allowed for considering friction. The

tangential contact between the pile and the surrounding soil was

defined using Coulomb's Law with a friction coefficient

estimated by the tangent of the friction angle between the two

materials. The normal behaviour was considered to be hard (no

penetration to each other) allowing separation after contact.

Figure 2. Three Dimensional Finite Element Model of Soil-Pile System:

(a) 3-D view and (b) Sectional view.

The whole system was modelled in six layers of soil as

found in site investigation (Manna and Baidya, 2009) and the

sectional view of the model is shown in Figure. 2(b). The

phreatic level was considered 1.25 m below the ground surface

and the effective soil pressure was applied in the whole

geometry according to this phreatic line. Soil behaviour was

considered as elasto-plastic. The displacement of soil had both a

recoverable and non-recoverable component under load.

Therefore, there was a need to include a failure criterion in the

elastic models to define the stress states that would cause the

plastic deformation. Mohr-Coulomb model was adopted for soil

to simulate the elasto-plastic behaviour. For analysis the FE

model material damping was considered. The Rayleigh damping