2693

Technical Committee 212 /

Comité technique 212

coefficients (

α

) and (

β

) was used to define in each layer and the

coefficients were determined from the relationship given below:

i i

i

D

2

2

(1)

where

D

i

= damping ratio corresponding to frequency of

vibration

ω

i

It was assumed that 60 rad/sec and 500 rad/sec were the limit

of predominant frequencies in dynamic testing i.e., all damping

values for different layers were less than the damping values

(

D

1

,

D

2

) considered here in this frequency range. The damping

values were taken from guidelines given by Bowles (1996).

Finally the (

α

) and (

β

) coefficients were calculated by using Eq.

(1).

The model was analysed in three calculation phases. First

gravity analysis was performed only in soil mass in vertical

Z

direction. In the next step, the pile-soil interaction was

introduced as well as static load was applied on the top of the

pile. A steel plate was provided on the pile head to simulate the

exact static load (8 kN and 10 kN) applied on pile. In the third

phase the dynamic FE analysis was performed by applying

sinusoidal vertical load on the pile using a dynamic multiplier

function at wide range of frequencies (5 to 60 Hz). According to

the values of eccentric moments (0.278 Nm, 0.366 Nm, 0.450

Nm and 0.529 Nm) and operating frequency of the motor, the

dynamic load amplitudes were determined.

4 RESULTS AND DISCUSSION

4.1 Validation of finite-element model

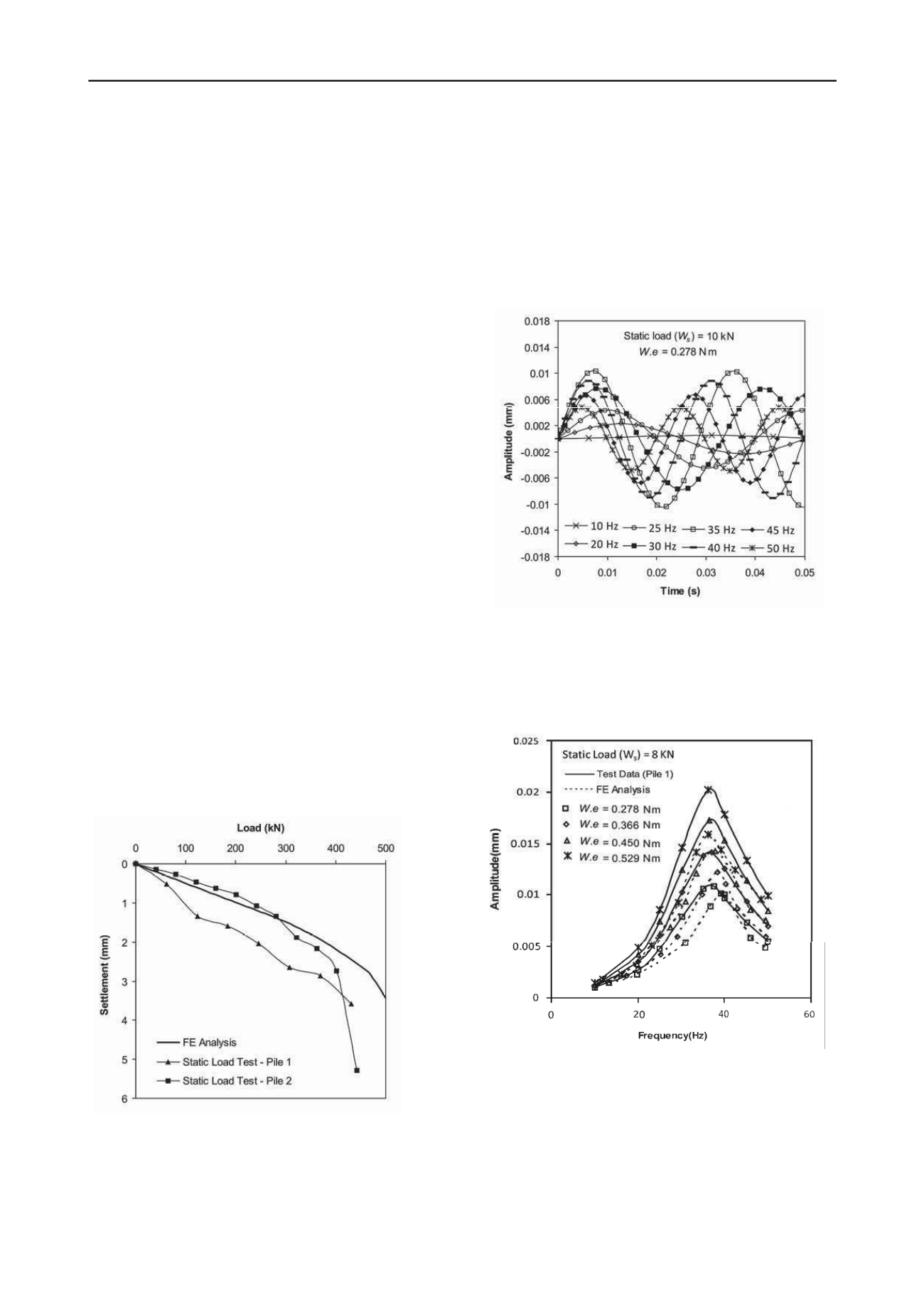

To monitor the boundary effect, the model was analysed with

different radius of boundaries. Based on the results, the

boundaries of soil mass around the pile were considered with a

radius of 30 m and height of 45 m to avoid the direct influence

of the boundary conditions. Static load analysis was carried out

and the results obtained from FE analysis were compared with

the static load test results. The comparison of static load test

results with the FE analysis is shown in Figure. 3. The predicted

settlement obtained from FE analysis is approximately 1.45 mm

and observed settlement is 1.45 mm and 2.3 mm for pile 1 and

pile 2 respectively at calculated safe load (283 kN).

Figure 3. Comparison of load verses settlement curve obtained from FE

analysis and static load test.

4.2 Comparison between finite-element analysis and dynamic

test results

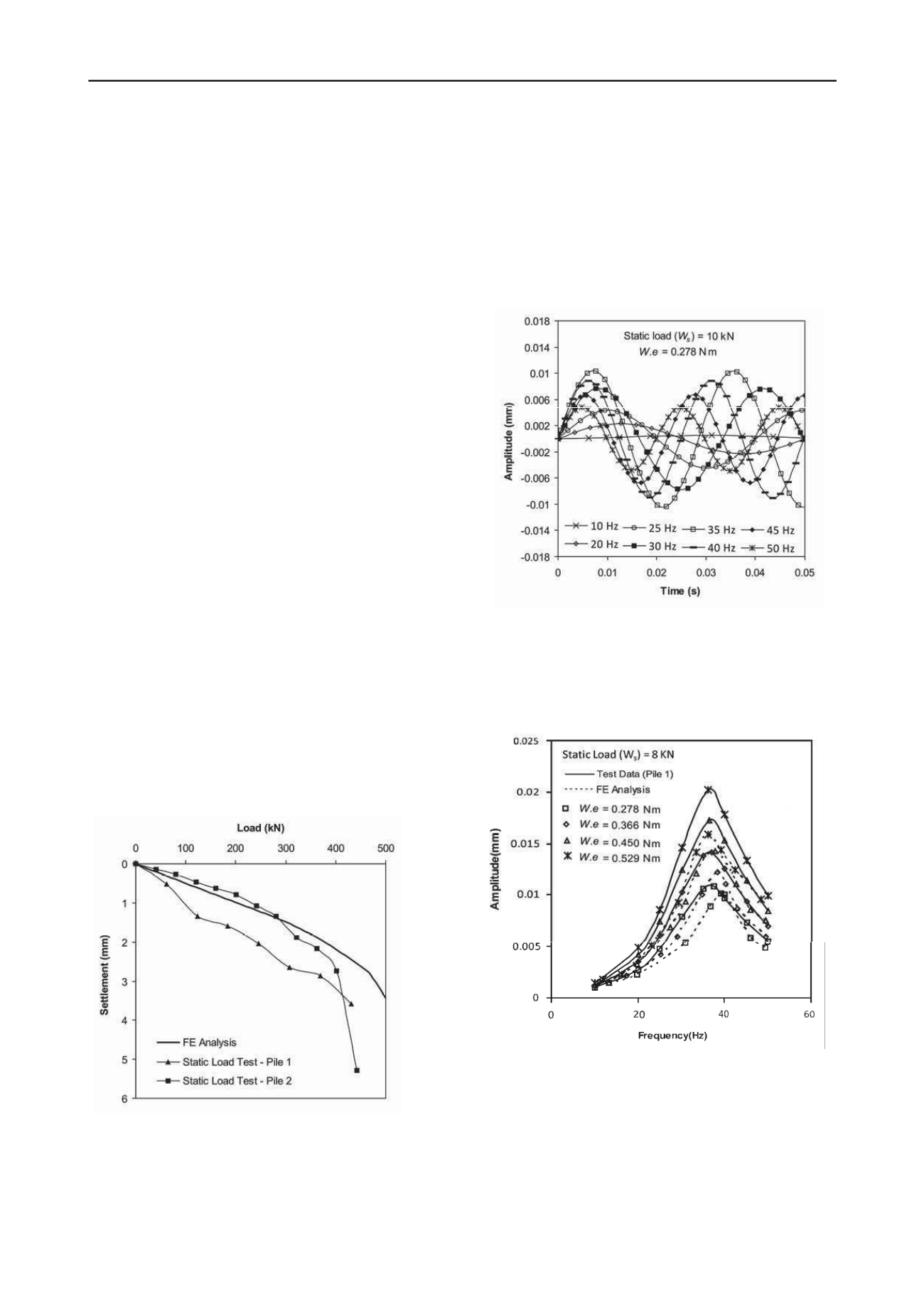

The time versus amplitude curves were obtained from FE

analysis at different operating frequencies of machine for

different static load and eccentric moments. A typical response

curve is presented in Figure. 4 for static load of 10 kN. From the

time versus amplitude curves, the frequency versus amplitude

curves were obtained and compared with the field vibration test

results.

Figure 4. Time-amplitude response of pile at different frequencies (FE

analysis).

The typical comparison of frequency-amplitude response

obtained from FE analysis and test results are shown in Figure.

5 and Figure 6 for pile 1 and pile 2 respectively.

Figure 5. Comparison of frequency-amplitude curve obtained from FE

analysis and dynamic test results (Pile 1).

It is found from these figures that the predicted resonant

frequency and amplitude are very close to the vertical vibration

test results. The resonant frequencies are decreased with the

increase of eccentric moments under same static load. This

phenomenon indicates the nonlinear behaviour of soil-pile

system obtained from FE analysis which is similar to the field

test results. This nonlinear response of the soil-pile system is

due to the material nonlinearity which is nothing but reduction