3046

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

ponds. When tipped into the landfill, the sludge exhibits a

degree of run-out (approximately 30 to 80m), but drains and

desiccates relatively quickly.

3.2

Operation of Landfill Cells

The landfills are formed in a series of cells. Each cell is

constructed by first constructing a containment bund of the high

strength granular RPCC waste and then placing the sludge

material behind it. After a sludge depth of 2.4m is achieved

within the cell, the sludge is allowed to dry and desiccate for

periods of 8 to 12 weeks. The next “lift” of the cell is then

carried out by constructing another 2.4m high bund of RPCC on

top of the previous one, and continuing the filling process with

sludge in the same way as before. Because each new bund is

half on the old bund and half on the sludge, the overall crest of

the cell tends to move generally up the valley and is commonly

termed “upstream” construction.

3.3

In situ sludge characteristics

3.3.1

General

Once the sludge has been deposited into the landfill, it gains

strength relatively quickly. The surfaces of the sludge cells

rarely pond rainwater and testing has shown the sludge mass

does drain and consolidate over time.

To investigate the nature of the sludge within the landfill,

boreholes and cone penetration tests (CPTs) were drilled

through three different completed cells. Locations were chosen

to represent the characteristics of both older and younger sludge

materials. A variety of tests were completed in situ and on tube

samples. The sludge was found to have the following typical

properties:

Bulk density: 1.4t/m

3

Undrained shear strength (after initial settling,

desiccation and consolidation): 30kPa and increasing

to greater than 100kPa at depth

Liquid limit (LL): 60% to 100%

Plasticity index (PI): 10 to 53

Effective angle of internal friction: 36° – 39°

3.3.2

Shear strength

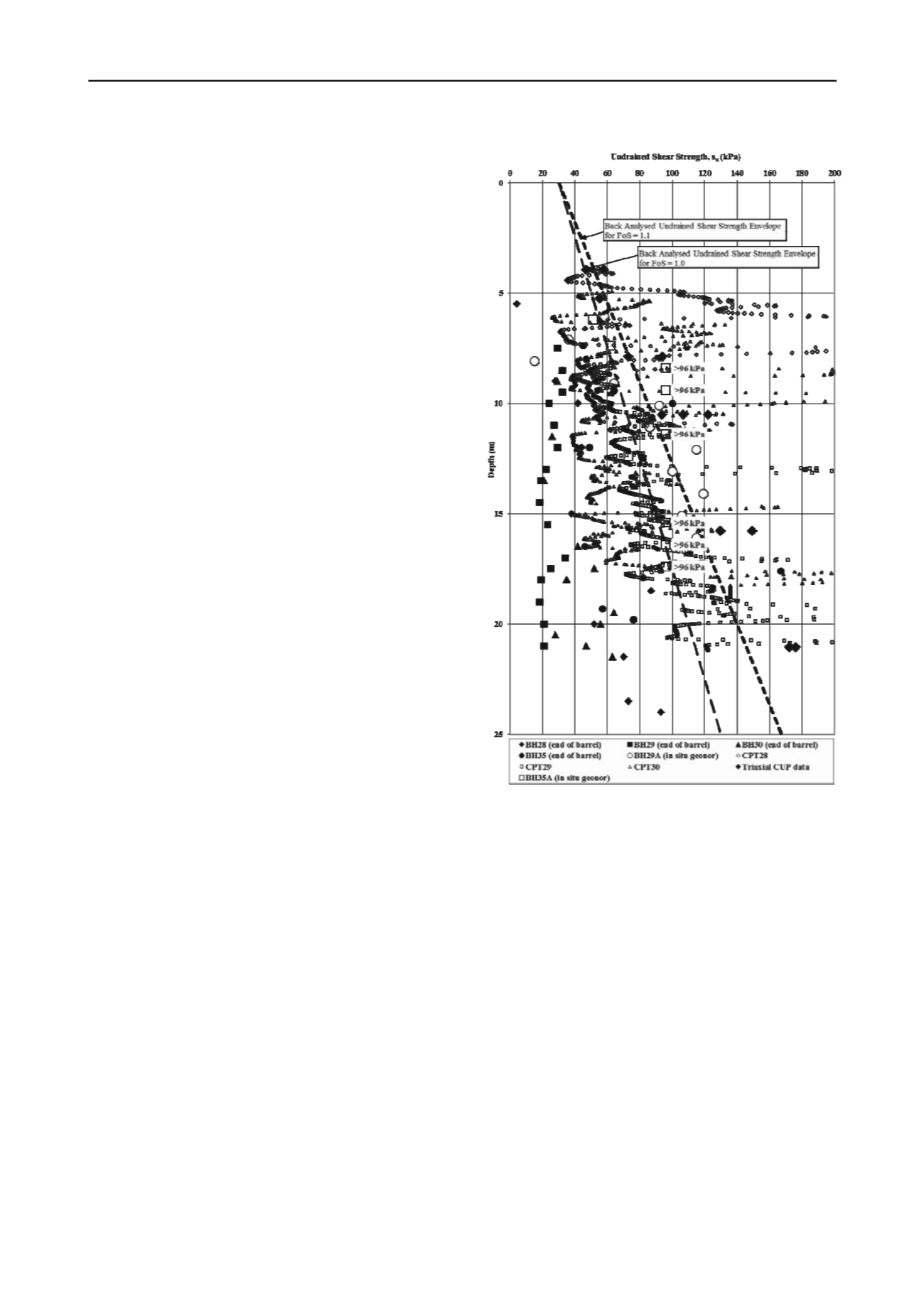

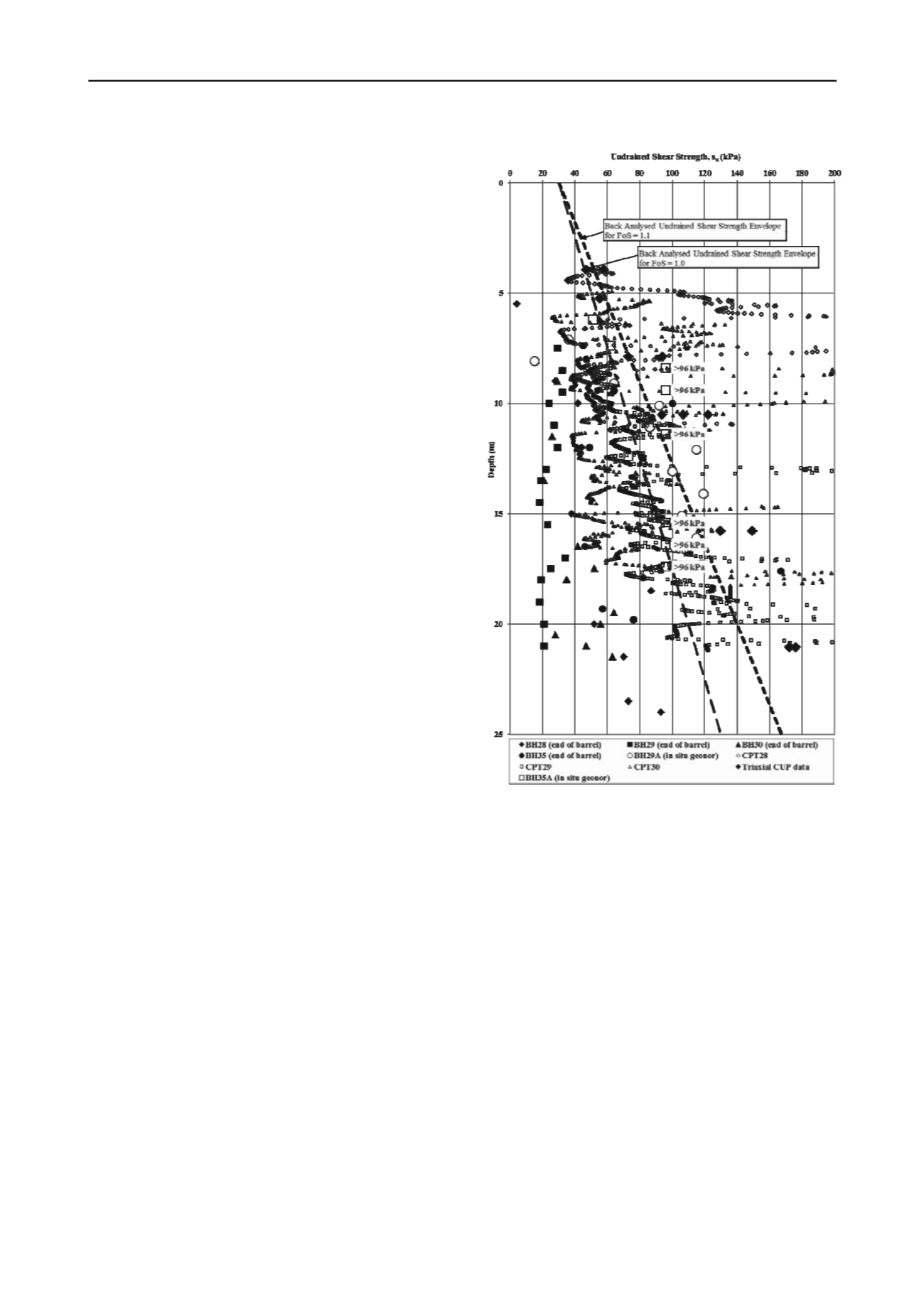

The in situ undrained shear strength (s

u

) was assessed using

Geonor vane, hand-held vane, CPT and triaxial CUP tests and

short term stability back analyses. The resultant shear strength

data from all approaches is summarized in a single plot in

Figure 1. Discussion about each method follows.

Geonor Vane:

This is the most direct in situ test method and

is given the highest weighting. Results show a clear indication

of strength increase with depth.

Hand-held Vane:

Measurements were taken with a small

blade vane at the end of the open borehole barrel. Results show

significantly lower values than the Geonor vane and triaxial

CUP data and a generally slightly decreasing trend with depth.

Such trends indicate a strong influence of sample disturbance

and this data should therefore be disregarded.

Figure 1. Undrained shear strength of sludge material with depth

CPT:

A method of deriving the undrained shear strength

from CPT data is given by Lunne, Robertson & Powell (1997).

The data show a clear trend of increasing strength with depth

and also, by comparing the different test locations, a clear

indication of strength increase with the length of time the sludge

has been in place.

Triaxial Tests:

The consolidated undrained triaxial tests

with pore pressure measurement (CUP tests) give a measure of

undrained strength (s

u

) with consolidation pressure (p´) and also

a s

u

/p´ relationship. This relationship gives an indication of the

expected increase in strength with depth after full consolidation.

The CUP data depth plotted on Figure 1 is based on the

effective consolidation stress applied to the sample for each test,

to represent a comparable overburden stress.

Back analysis:

Based on historical annual survey data, the

maximum free-standing slope face height for an operating cell

was 24.5m with a slope of 1.2H: 1V. A back-analysis of this

maximum free standing slope has been carried out using

equilibrium software (Slope/W). An undrained shear strength

profile for the sludge material of 30kPa at the surface,

increasing at 4kPa per meter with depth is required for a safety

factor of unity. Similarly, an undrained shear strength profile

for the sludge material of 30kPa at the surface, increasing at

5.5kPa per meter with depth is required for a safety factor of

1.1.