3047

Technical Committee 215 /

Comité technique 215

Bund failure has never occurred at the site. Therefore, it can

be inferred that the undrained shear strength of the sludge

material is higher than the back-analysed undrained shear

strength envelope (assuming a safety factor of unity). The back-

analysed shear strength envelopes (refer Figure 1) show that the

Geonor vane and triaxial undrained shear strength data closely

fit the back analysed shear strength envelope for a safety factor

of 1.1 and is therefore more representative of the sludge

undrained shear strength characteristics.

3.3.3

Pore pressure monitoring

Six pore water pressure transducers were installed in two

boreholes at various depths below the ground surface. Pore

water pressures were measured over a period of one month.

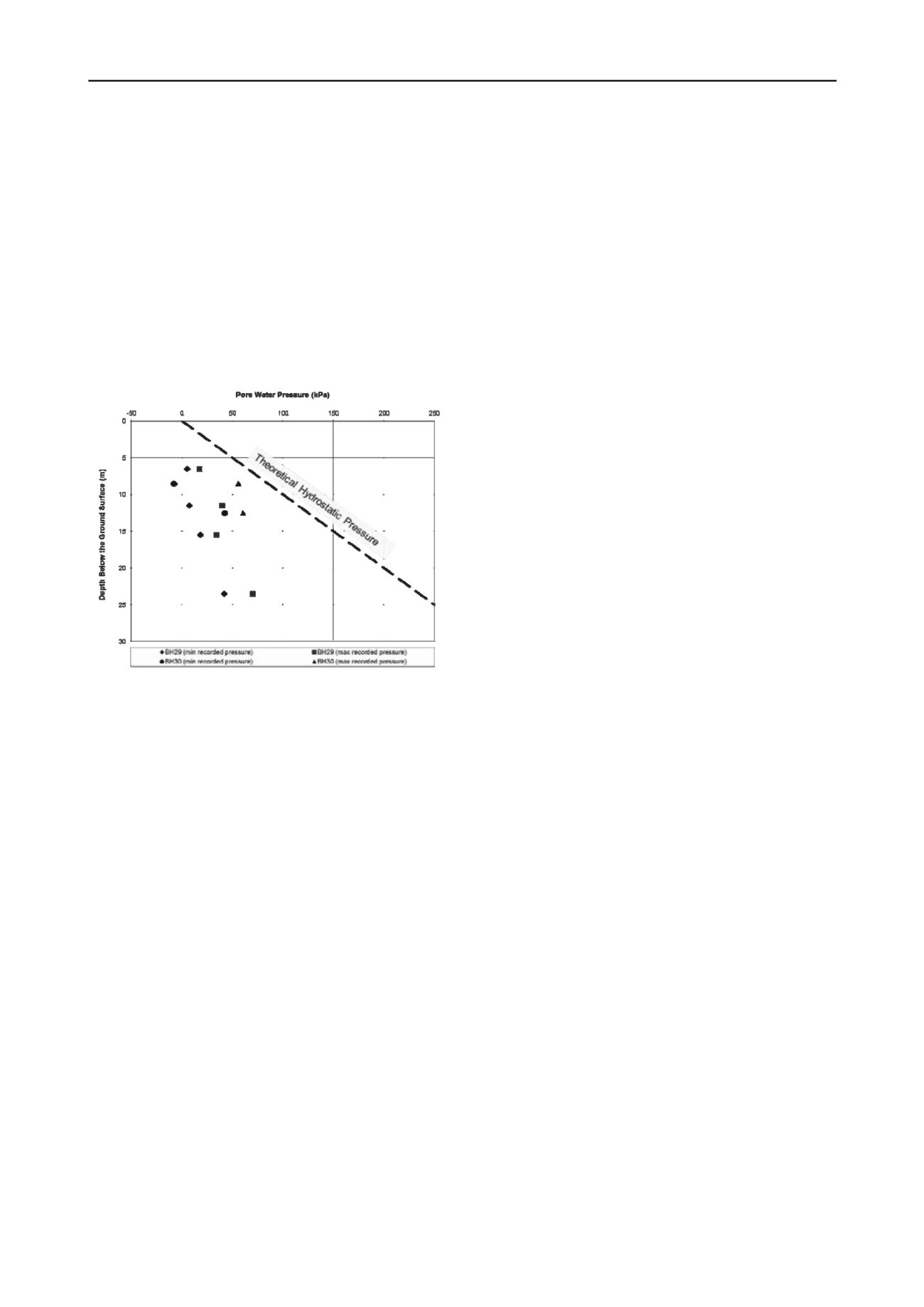

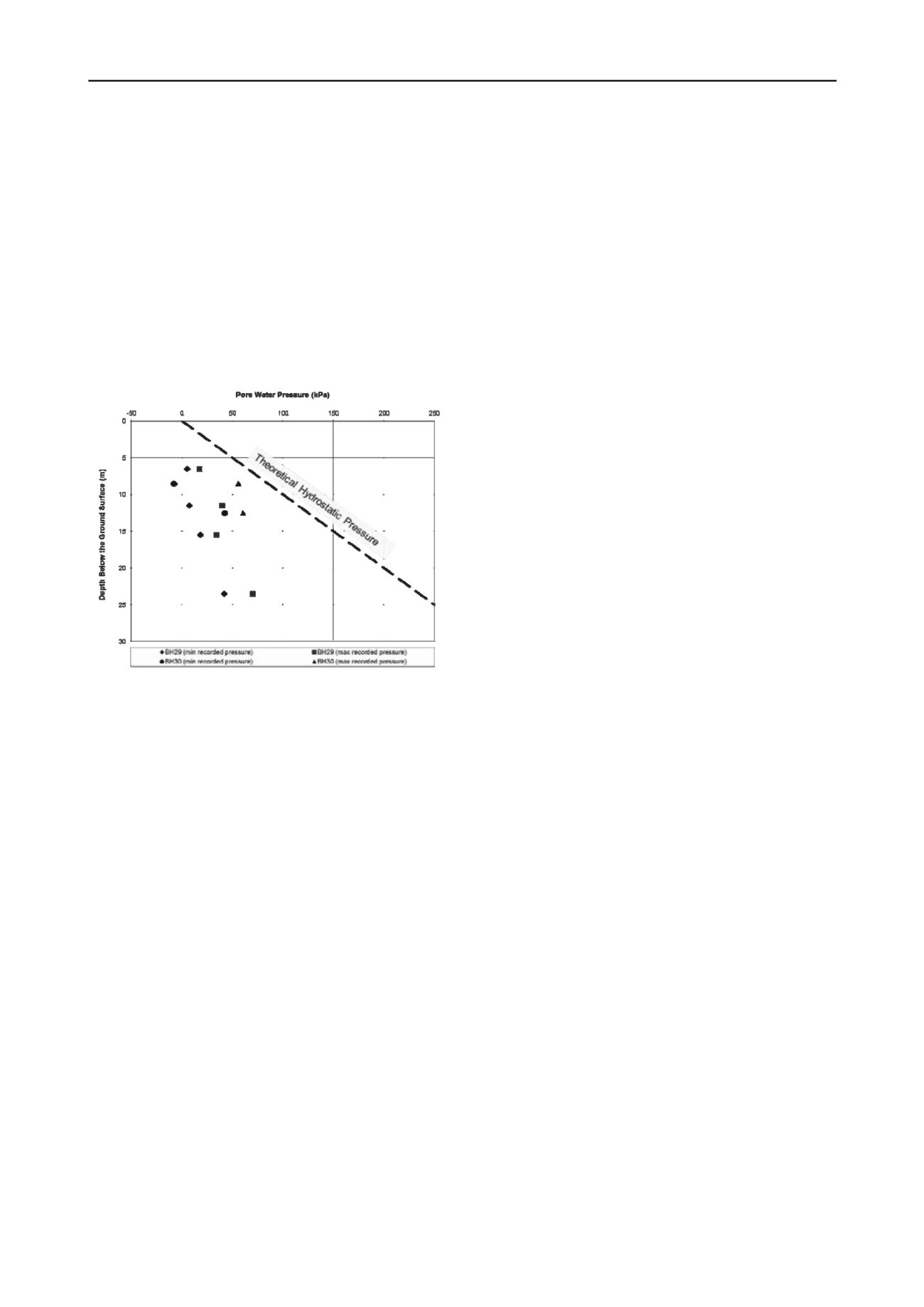

Figure 2. Pore water pressure distribution in sludge with depth

The sludge pore water pressure monitoring results are

presented in Figure 2. The maximum and minimum ground

water pressures measured by the transducers are presented as a

function of depth below the ground surface. The results indicate

that the pore water pressures in the sludge material range from

10kPa to 60kPa and are significantly lower than the theoretical

pore water pressures for hydrostatic conditions with the water

table at the ground surface. These results demonstrate the sludge

mass is able to dry out and desiccate prior to subsequent

placement of the above sludge layers and that the sludge mass is

able to drain within the landfill cells.

4 LIQUEFACTION

The assessment of liquefaction potential of the sludge waste has

been approached using CPT data and Atterberg Limits.

4.1

CPT-based liquefaction assessment

Liquefaction analyses using the CPT data have been undertaken

using the assessment methods developed from the 1998

NCEER/NSF Workshop, supplemented and updated with the

more recent recommendations for liquefaction assessment

including the works of Zhang et al. (2002), Cetin et al. (2004),

Moss et al (2006a), and Moss et al. (2006b).

The CPT data show that the sludge materials are very

cohesive (i.e. they have Ic values greater than 2.6) and

therefore, in theory, are not susceptible to liquefaction. The

calculated liquefaction factor of safety (derived from CRR

7.5

)

for the majority of the CPT data was above 1.0 for a peak

ground acceleration of 0.17g (10% probability of exceedance

for a 30 year period).

4.2

Liquefaction Susceptibility using Atterberg limits

Over the past few decades it has been assumed that fine-grained

soils (silts and clays) do not liquefy. Recent research has shown

that, under some circumstances, fine grained soils (such as

sludge) may be susceptible to liquefaction and there have been

various suggested criteria for defining the limits.

Seed et al. (2003) recommended an area on the Casagrande

Plasticity Chart within which soils should be classified as

“potentially liquefiable”. Out of nine, eight results are all well

outside the potentially liquefiable region. Therefore the waste

mass as a whole is not susceptible to liquefaction according to

these criteria. Some small pockets or zones may be more

susceptible than others, but will not govern the behaviour of the

overall material mass.

Bray & Sancio (2006) suggested criteria based on PI and the

ratio of natural water content to the liquid limit (w/LL). Again,

only one result out of nine plots within the “Susceptible” region.

Boulanger & Idriss (2006) suggested that materials can be

expected to exhibit clay-like behaviour ( i.e. non liquefiable) if

they have PI value of greater than 7 and that fine-grained soils

with PI values less than 7 should be considered as potentially

exhibiting “sand-like” behaviour (i.e. liquefiable). The PI data

for the sludge range from 10 to 53 and fall into the “clay-like”

category, indicating the material is not susceptible to

liquefaction.

4.3

Liquefaction conclusion

It is concluded that the landfill materials are not susceptible to

liquefaction under any credible level of shaking. In addition to

this, however, it should be noted that the level of shaking under

operating conditions (10% probability of exceedance in 5 years)

is only 0.06g, and this is unlikely to exceed the strain threshold

for liquefaction to occur for any type of material, except very

loose sands.

In the long term the final landfill geometry will have a

maximum slope of 5H: 1V and will be made up of consolidated

sludge in many separated cells with numerous effective RPCC

“chimney drains” extending up full-height through the fill.

Even if liquefaction could occur, it would be localised and

confined within the cells, with little risk of significant

displacement.

5 DESIGN

Based on in situ and laboratory testing at the West Landfill, the

sludge design parameters that have been selected for the cell

design of the East Landfill are summarised in Table 1.

A seismic reduction factor was adopted for the sludge shear

strength envelope to account for potential cyclic strain softening

that may occur within the sludge during seismic loading. For a

7.5 magnitude earthquake, Boulanger and Idriss (2007)

recommend a ratio of cyclic undrained to static strength for

natural clays/silts is 0.8. Therefore the static strength was

reduced by 20%.

Table 1. Sludge design parameters used for design of East Landfill

Test Method

Undrained

Drained