1868

Proceedings of the 18t

h

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

• Optical strands (fiber optics, OSMOS)

• Traditional inclinometer (GEO)

• Draw Tower Grating (fiber optics, Belgian Building

Research Institute (BBRI))

• BOTDR (fiber optics, Cambridge University)

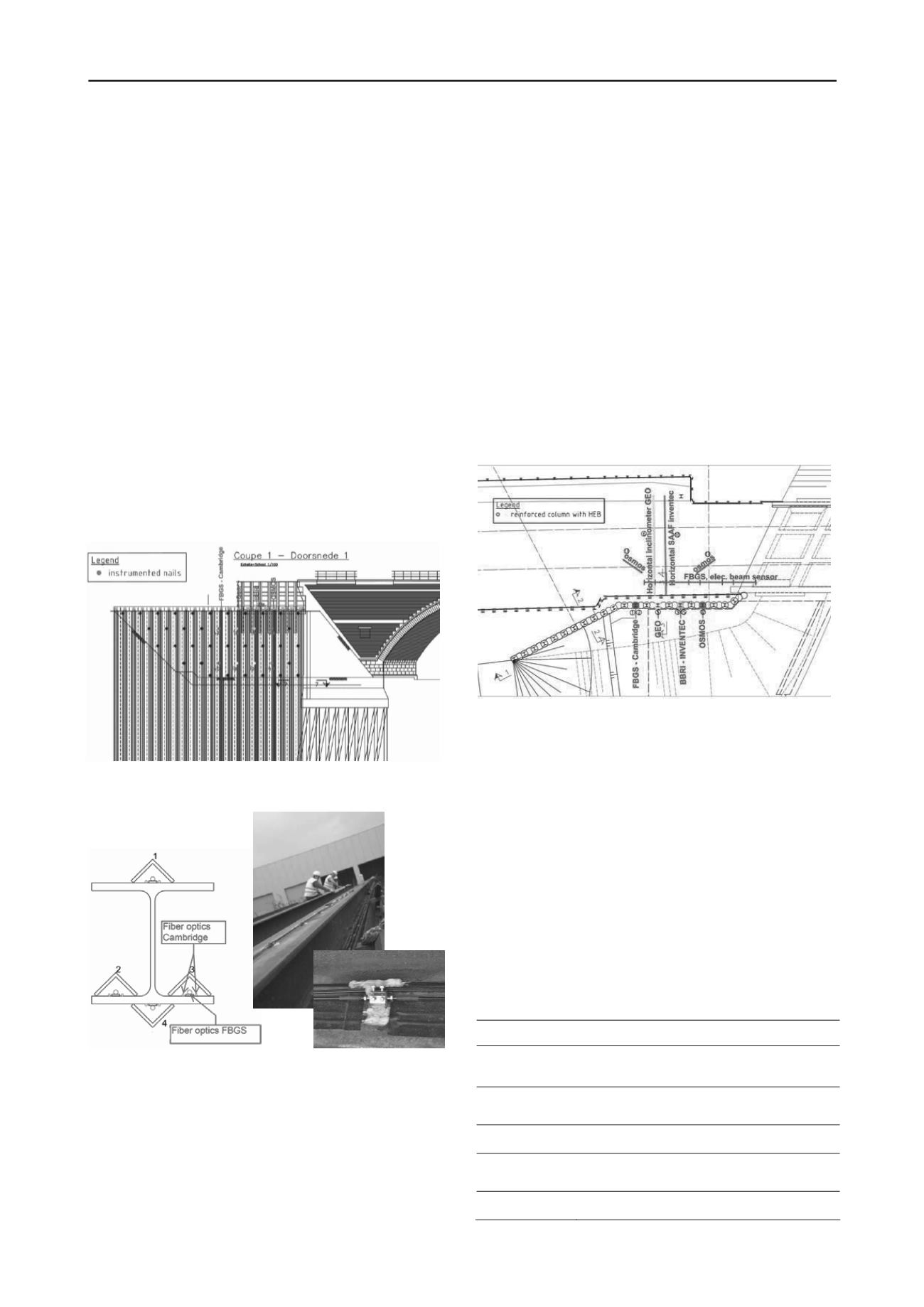

The equipment for measuring the deformation of the wall or

stresses in the wall, is placed on 4 HEB profiles which are

lowered over their full length in the jet grout wall. Figure 2

shows a front view of the excavation site and the location of the

instrumented profiles is indicated in red. Figure 3 shows a

drawing and some pictures of the FBG and BOTDR fibers

which are fixed to the HEB profile. The FBG fibers are fixed in

small anchor blocks which are welded to the HEB profile (size

of the anchor blocks is 18mm x 18mm). Those anchors are

placed every 0.5m in the upper 8m of the profile and every 2m

for the lower part. The BOTDR fibers measure the strain

continuously, but are locally glued to the HEB-profile (every

0.5m and 2m) for better comparison with the FBG data. To

measure deformations and moments perpendicular to the wall,

fibers are placed on the top and bottom flange. To measure

possible deformations parallel to the wall, two extra fibers are

placed at the sides of the bottom flange. Extra L-profiles, placed

above all fibers, are used as a protection during installation.

The other instrumentation was similarly fixed on the HEB

profiles by welding or gluing.

Figure 2. Front view of excavation with indication of instrumented HEB

profiles.

Figure 3. Sketch and pictures of a HEB profile which was instrumented

with two optical fiber systems.

1.2.2

Settlements behind the jet grout wall

As one of the main concerns during an excavation are the

settlements of the soil (and inherently the infrastructure) in the

vicinity of the excavation, the vertical deformation of the soil

behind the wall is one of the important parameters to be

monitored. In this project specifically, deformations of the

railroad track are to be avoided.

The deformations behind the wall are measured:

• with two horizontal inclinometers (a traditional one and a

continuous SAAF inclinometer) which are placed perpendicular

to the wall in the ballast underneath the rails. The inclinometers

are attached to a Berliner wall, which is located at one side of

the rails. It is assumed that this creates a fixed point;

• topographically: the rails are marked with survey nails

along a length of 100m and vertical deformations are measured

by topographic levelling at different stages of the project;

• with electrical beam sensors placed on the railway sleepers;

the beam sensor consists of an electrolytic tilt sensor attached to

a rigid metal beam. The beam, one to two meters long, is

mounted on anchor bolts that are set onto the sleepers. The

sensors are linked end to end, as to allow displacement values to

be accumulated from anchor to anchor to provide a profile of

differential movements or settlement.

• with two optical strands, placed at a certain angle with the

railway on the railroad tracks .

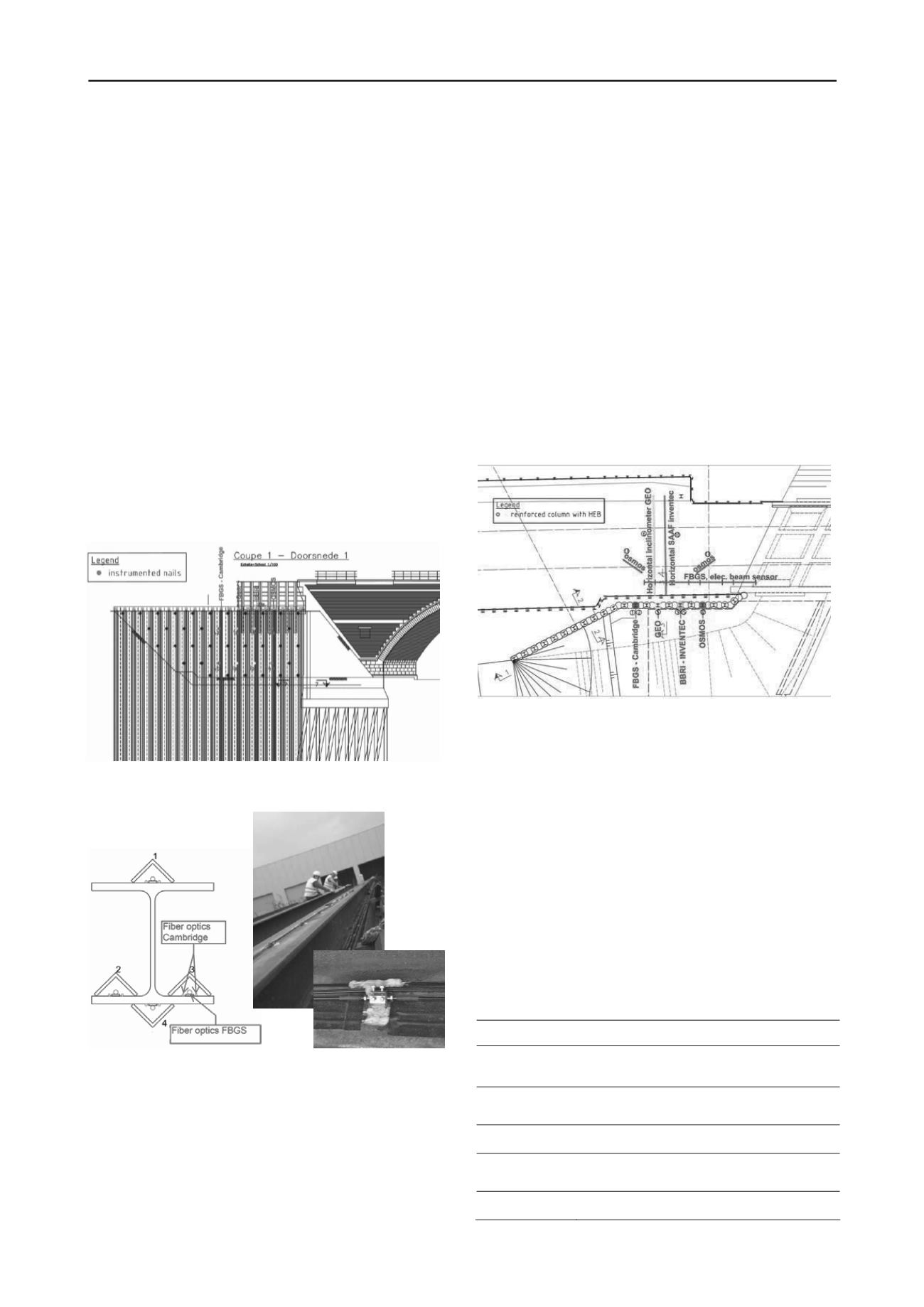

Figure 4 gives a top view of the instrumentation which is

placed on or underneath the railway tracks. It also shows the

different HEB profiles which were instrumented.

Figure 4. Top view of installed equipment.

A more detailed description of all installed equipment is

given in Van Alboom et al. 2012.

1.3

Design of the jet grout wall

Calculations of the jet grout wall are implemented in FLAC2D

by TUC Rail. They result in a maximum horizontal

displacement of 21 mm, a maximum moment of 65KNm and a

maximum settlement of 9mm behind the wall in the final

excavation phase. A more detailed description of the

calculations is given in Verstraelen et al. 2013.

1.4

Sequence of the execution phases

Table 1 gives the sequence of the execution phases, retrieved

from photos made on site every hour. As continuous monitoring

was performed, the influence of the executed works on the

movement of the soil could be assessed.

Table 1. Execution phases.

Date

information

22-23/10/2011

Installation of the instrumented HEB profiles

in the jet grout wall

3/11/2011

Excavation up to 1,25m below the top of the

concrete beam

06-09/11/2011

Installation of the first row of nails

06-07/12/2011

Excavation up to 3m below the top of the jet

grout wall

08-12/12/2011

Installation of the second row of nails