1866

Proceedings of the 18t

h

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

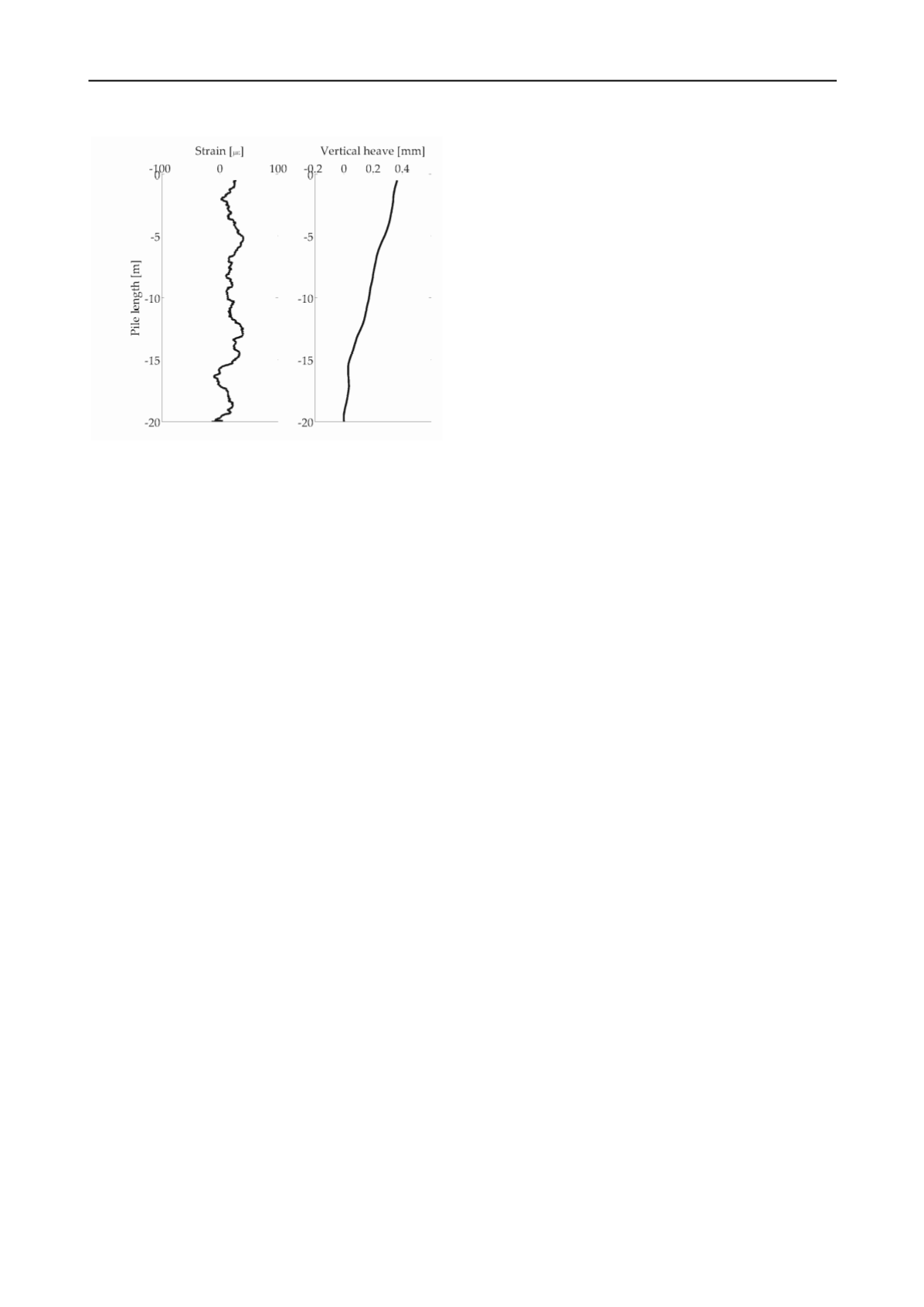

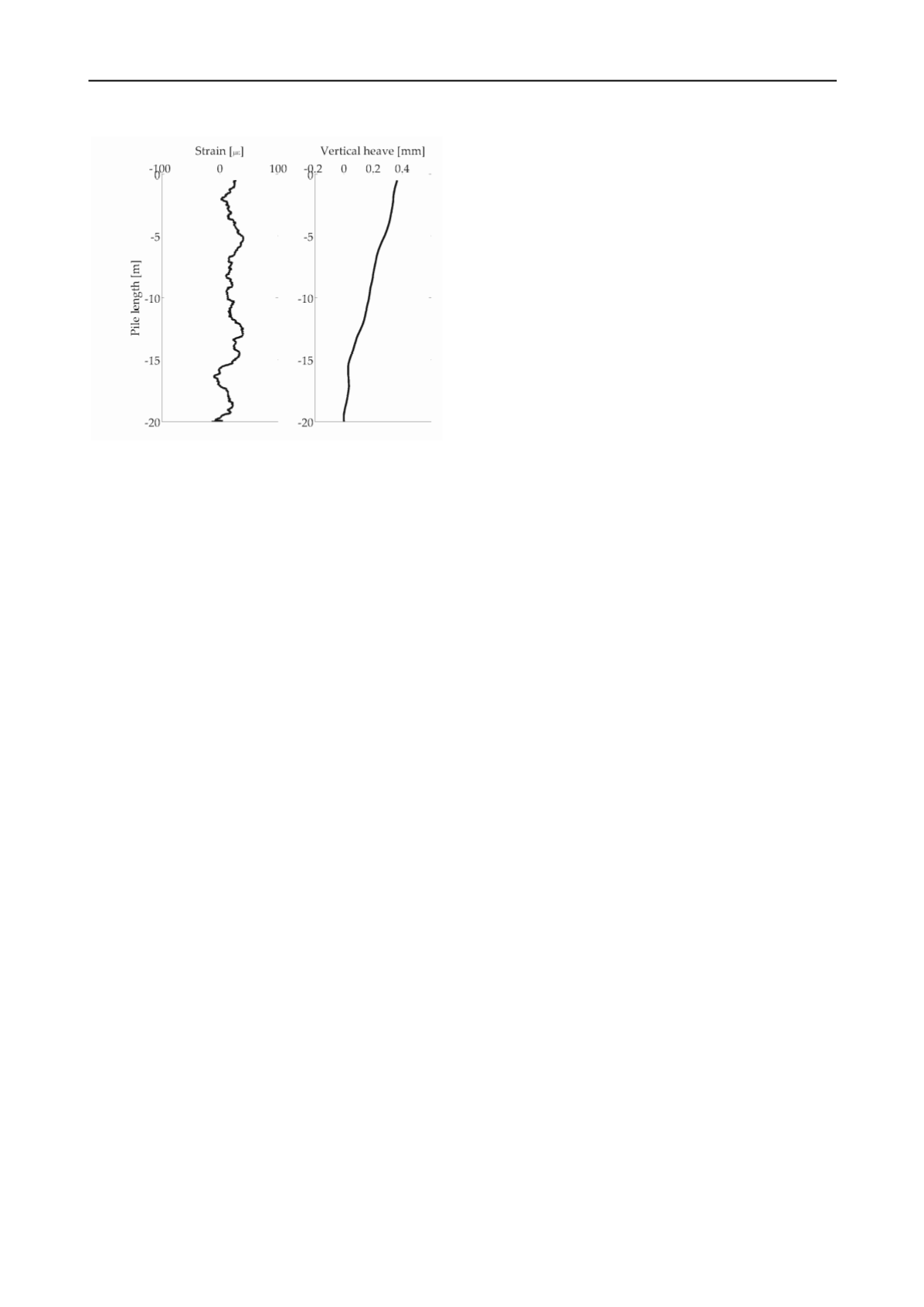

Figure 6. Strain profile along the borehole with interpreted ground

heave profile.

3.3 Discussion

The magnitude of vertical movement measured from pile E47

during the demolition is smaller than 1mm. The resulting force

generated at the top section of the pile is estimated to be around

3,

800 kN by assuming the pile Young’s modulus is 26GPa, and

this is relatively large for a pile reinforced with only a nominal

steel cage and justifies the concern towards the integrity of the

pile post demolition. The significant advantage of using optical

fibre instrumentation is that a continuous and full length strain

profile is measured, which allows assessment of the potential

for cracking of the pile as a result of the demolition induced

(load removal) strains. This would be visible as localized sharp

peaks within the strain profile and from such data it would even

be possible to calculate potential crack thickness. There are no

signs of cracking along pile E47 throughout the whole depth

and as such there appears to be no visible signs of any

detrimental effect of the demolition process up to the

05/10/2011.

With regard to the instrumented borehole, very small strain

variation was observed during the monitored demolition

process. Such small strains are indicative of small heave forces

generated. This could be as a result of both the location of the

borehole, which was close to the edge of the basement, and

almost certainly as a result of the confining effect of the existing

piles and basement slab.

There remain a large number of exiting piles that have not

been instrumented and will be reused. Nevertheless, the

monitored piles and borehole gave a good indication of the

typical response of the existing piles beneath 6 Bevis Marks to

the removal of building load during demolition. The results

were an essential part of the proofing process and validated the

reuse strategy.

4 CONCLUSIONS

Currently the primary source of information available for

considering foundation reuse are

limited to “as built” design and

installation records. Although in the future these may be more

comprehensive than what are currently available on

development sites, the extent of re-use will be limited to the

quality of such records. This will in turn constrain the future

development options for such sites and is likely to influence the

asset values of the site and the existing development, and the

viability of redevelopment.

There are developments taking place continuously where

more piles are being added to those installed previously, either

re-using the existing piles, but more often than not, ignoring the

capacity of existing piles, further restricting the future

development potential. In the UK high capacity bored piles

have been widely used since the 1950s and it is not unusual for

a site to be on its second or even third set of piles, all of which

will obstruct and constrain further developments.

Traditionally, low strain pile integrity testing is carried out to

confirm that new piles have been constructed correctly and no

discontinuities exist. It is also used to assess the integrity of

existing piles for reuse, usually with mixed success. Such

testing is often not appropriate for pile reuse as,

To carry out a low strain integrity test, the top of the pile

needs to be exposed and structurally separated from other

foundations. This is not possible where pile caps, slabs and

basement substructures are to remain in place for reuse.

Such testing only confirms if there is a crack, not how big it

is or what is below it. When demolishing an existing

building, the expected ground heave may crack the piles to

some degree, such cracks are expected to be small and to

close up upon pile reload but these tests cannot confirm this.

An alternative solution is to install fibre optic strain

measuring devices into existing piles that have been cored full

depth and into future piles on installation, producing a smart

foundation system. Making this provision for the future will not

only increase the potential for re-use and increase its asset

value, but is also likely to make the asset more valuable when

compared to other properties where such

“future proofing” has

not been incorporated. Such an approach will allow monitoring

of how the piles actually perform under loading, unloading,

reload and during the life cycle of the building. Results could be

used to further advance our understanding of actual foundation

response during the construction phase and operation of such

buildings.

5 ACKNOWLEDGEMENTS

The authors would like to thank Waterman Structures Ltd for

their initial foresight in assessing the re-use potential of the

foundations on the Bevis Marks project and their considerable

involvement in developing and implementing the pile reuse

strategy and associated instrumentation and monitoring works.

6 REFERENCES

Begaj Qerimi L. and McNamara, A. M. 2010. Physical modelling for

pile foundation re-use.

In Physical Modelling in Geotechnics -

Proceedings of the 7th International Conference on Physical

Modelling in Geotechnics 2010, ICPMG 2010

, volume 2, pages 733

737, 2010.

Klar, A. Bennett, P.J., Soga, K., Mair, R.J. Tester, P., Fernie, R., St

John, H.D. and Torp-Peterson, G. 2006. Distributed strain

measurement for pile foundations.

Proceedings of the Institution of

Civil Engineers: Geotechnical Engineering,

159(3):135-144, 2006.

Leung, Y.F., Soga, K. and Klar, A. 2011. Multi-objective foundation

optimization and its application to pile reuse.

In Geotechnical

Special Publication

, pages 75-84, 2011.

Mohamed, H 2012. Temperature and strain sensing techniques using

brillouin optical time domain reflectometry.

Proc. SPIE 8346,

Smart Sensor Phenomena, Technology, Networks, and Systems

Integration 2012, 83461M

, 2012.

British Standard, 1985. Structural use of Concrete

–

Part 2: Code of

practice for special circumstances,

Reprinted incorporating

amendments Nos. 1 and 2,

BS 8110-2:1985