1878

Proceedings of the 18t

h

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

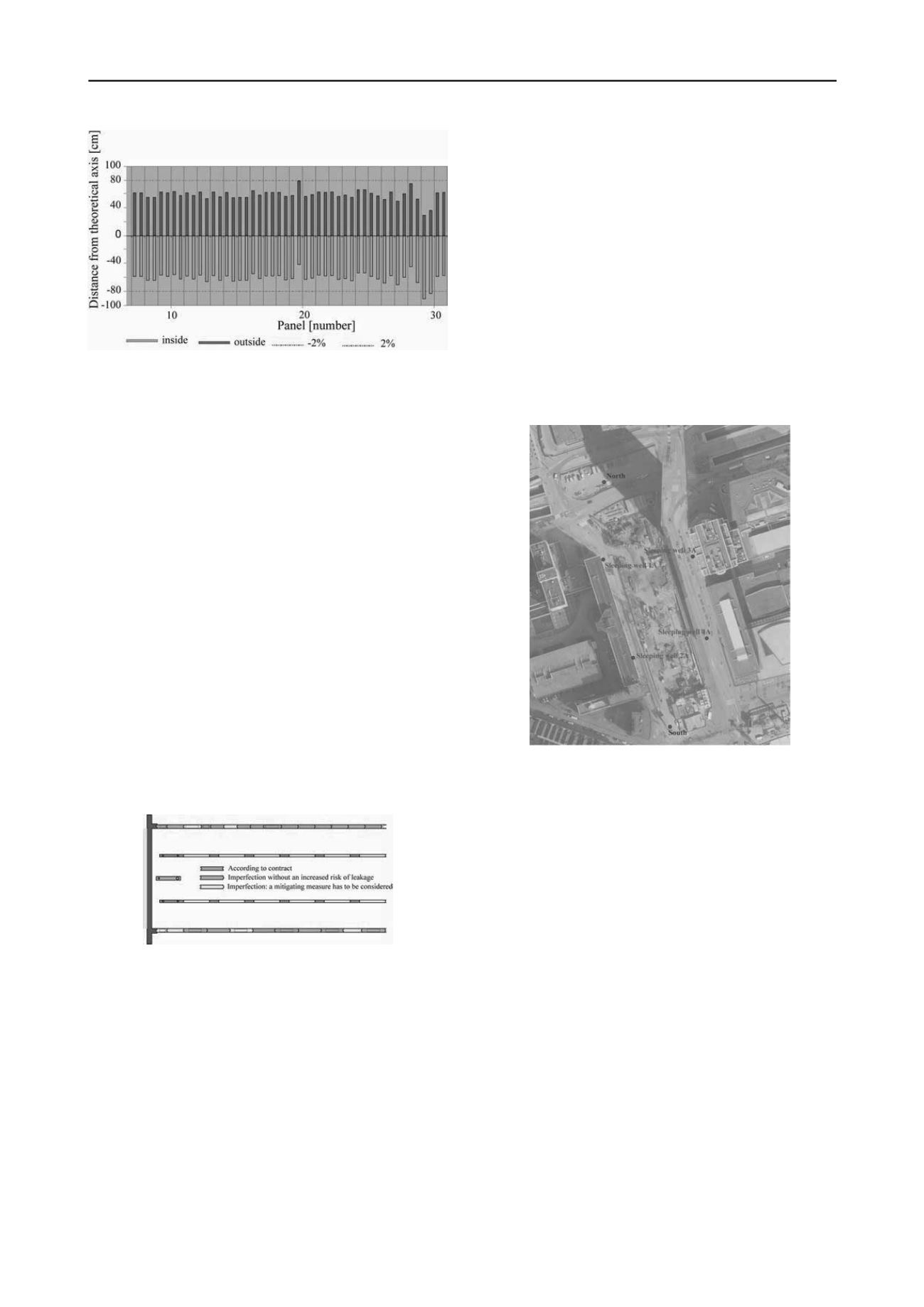

Figure 5. Relative position of the panels at 40 m depth. Dark represents

the outside of the diaphragm wall; light the inside. The dotted red lines

represent the 2% deviation of the verticality.

6.4 Non-standard measurement techniques

Reference is made to Doornenbal et al. (2011) and Spruit et al.

(2011) for more information on the experiments using non-

standard measurement techniques to detect imperfections in

diaphragm walls, which appeared to be quite successful.

6.5 Increased risk of leakage

Combined interpretation of Figures 3 to 5 reveals areas where

an increased risk of leakage has to be anticipated for, as

compared to normal conditions. Following aspects have been

evaluated using the outcome of the interpretation of the as-built

records:

- a missing/damaged water-stop;

- no cleaning of the concrete surface;

- the elapsed time between refreshing of the bentonite and

the commencement of concreting greater than 24 hours;

- encountered problems during the stop end removal works;

- concrete characteristics;

- wall thickness reduction > 0.20 m (Figure 4),

- reduced overlap < 0.80 m (Figure 5).

An overview of locations with an increased risk of leakage

along the excavation circumference has been generated as

shown in Figure 6.

Figure 6. Increased risk of leakage.

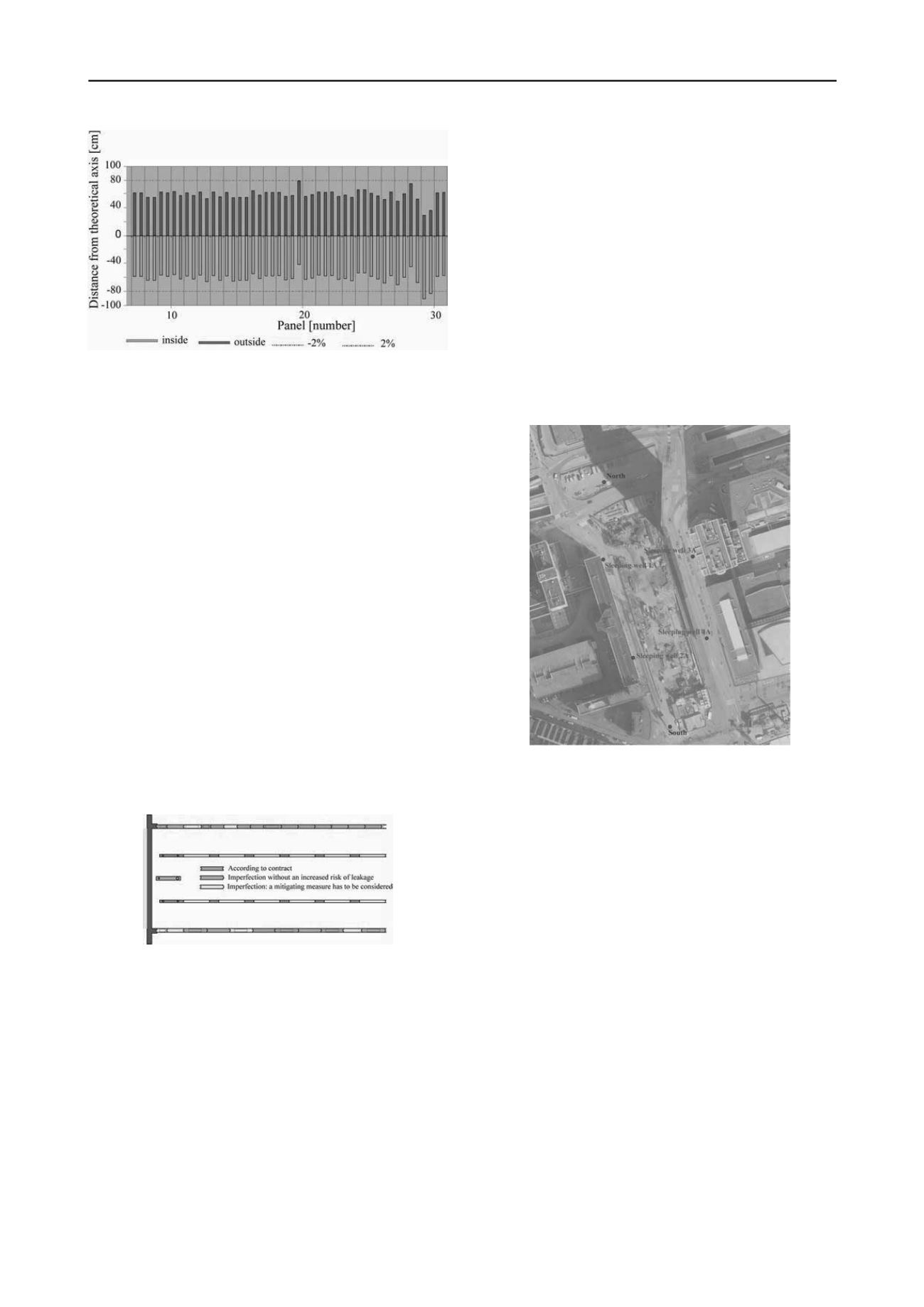

Subsequently, a number of mitigating measures has been

defined for each individual panel as to compensate the increased

risk. It appeared from the overall risk analysis that careful

positioning of four ‘sleeping’ wells around the excavation

would provide sufficient means for acting in case of leakage at

any of the identified weak spots as shown in Figure 7.

Additionally, for a number of panels it has been recommended

to call for an intensified inspection and repair program (when

necessary) during the excavation works.

7 CONCLUSIONS

The realized diaphragm wall panels were in general of sufficient

quality. A number of hot spots along the circumference of the

building pit with a increased risk of leakage were identified.

The risk profile related to leakage was considered to be at an

acceptable level if a number of mitigating measures were

executed. These measures were supplementary to the required

measures in the contract.

A pumping test to check the water tightness of the

diaphragm walls is very valuable in case the subsoil conditions

are similar to those in Rotterdam.

Supervision of the construction process appeared to be an

important mitigating measure, in combination with the

registration of the execution data of the diaphragm wall, and the

subsequent analysis of these data.

The extensive acquisition of data as such is not new for the

construction of diaphragm walls, but the systematic analysis of

the data, as performed for this project, has not been noticed so

far. It is recommended to do so for all future projects.

The positioning of ‘sleeping’ wells can be considered as a

major mitigating measure, and is a lesson learned from the

construction of the (leaking) diaphragm wall at metro station

CS.

Figure 7. Positioning of the four ‘sleeping’ wells east and west of the

building pit. Additional wells may be installed at the north and south

side in case of a calamity in the northern or southern wall.

ACKNOWLEDGEMENTS

The work on this subject of former colleagues Edwin Dekker

and Rens Servais is gratefully acknowledged. Records of the

execution of the diaphragm walls have been provided by the

contractor Besix BV. Colleague Arie van de Heerik collected

most of the records, and Ton de Keiser prepared the illustrations

in this paper.

REFERENCES

Doornenbal, P., Spruit, R., and Hopman, V. 2011. High resolution

monitoring of temperature in diaphragm wall concrete

. Proc.

FMGM2011, Berlin.

EN 1538 2010.

Execution of special geotechnical work – Diaphragm

walls.

Hannink, G. and Thumann, V.M. 2007. Existing structures govern

building methods near Rotterdam Central Station

. Geotechniek,

special edition, September, 2007, 26-29.

Spruit, R., Hopman, V., van Tol, A.F., and Broere, W. 2011. Detection

of Imperfections in Diaphragm Walls, field test results.

Proc.

FMGM2011, Berlin.

Thumann, V.M., Hannink, G. and Doelder, B.R. de 2009. Ground

freezing and groundwater control at underground station CS in

Rotterdam.

Proc. 17

th

Int. Conf. On Soil Mech. and Geot. Eng.,

Alexandria.