2287

Technical Committee 208 /

Comité technique 208

4 GROUND ANCHOR CAPACITY ASSESSMENT

PROCEDURE AND CASE STUDY

For the purpose of quantitative assessment on the ground anchor

capacities, and with regard to the ground anchors performance

on the sloping terrain application is the goal of this procedure.

Based on the inspection and assessment items, this article shall

introduce a new set of ground anchor capacity assessment

procedure, in hoping to establish a standardized way to

quantitatively evaluate and assess ground anchoring. Such

procedure shall comprised of exterior inspection, anchor head

inspection, endoscopy inspection and lift-off test. The findings

based on Table 1 distribution is point based. The total score

will then be carried to Table 2 to evaluate (β) and classification.

Sloped terrain performance and ground anchoring total capacity

shall be classified based on Table 2 standards. Ground

anchoring total performance assessment classified as A or B

grade, respectively, will be given corresponding effective

rehabilitation to ensure the full and reliable capacity of the

ground anchors.

Figure 4. Free section exposed portion length

investigation

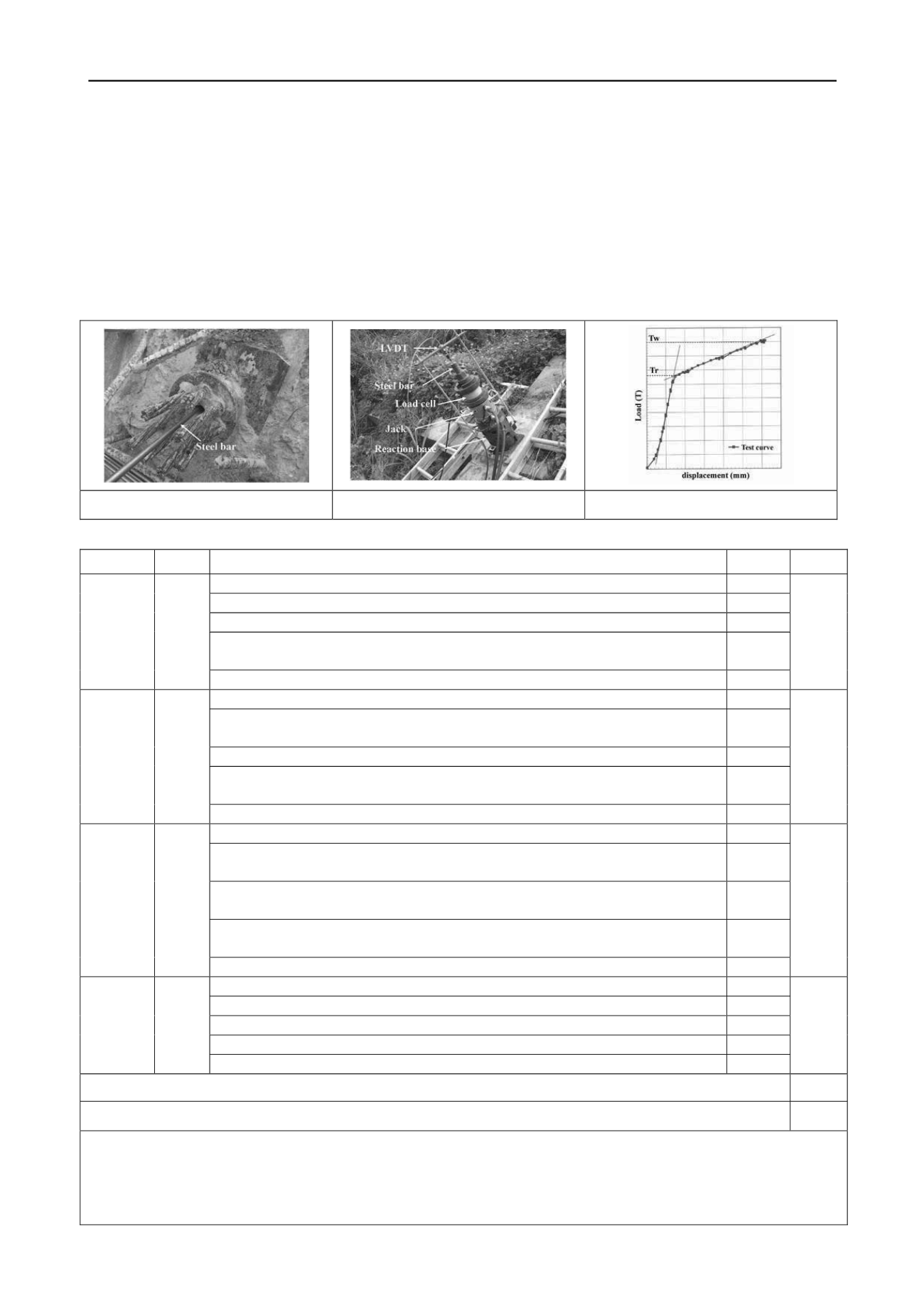

Figure 5. Lift-off test installation

Figure 6. Lift-off test curve diagram

Table 1. Score of anchor capacity assessment

item

scoring Content of inspection

Weight

subtotal

Buckled or detached.

0

Greater than 2mm separation from bearing plate or water corrosion is severe.

0.25

Anchor head protected seat and bearing plate separation is less than 2mm.

0.50

Anchor head protected seat surrounded by water seepage, efflorescence or anchor seat outside is

slightly damaged or water corrosive level is moderate.

0.75

Exterior

inspection

10

No observable anomalies or water quality is normal.

1.0

Assembly came apart(clamp became loosened, steel tendon shrinkage or broken)

0

Anchor head surface appeared rusted and cracked, spread over 50% of the surface, steel tendon

section is deformed due to corrosion.

0.25

Anchor head surface appeared rusted and cracked, but spread less than 50% of the surface.

0.50

Slightly corroded or water seepage. Anchor head appeared rusted, but the depth of the rust is quite

thin, not measurable or lesser than 0.1mm.

0.75

Anchor

head

assembly

inspection

15

No corrosion or water seepage is present.

1.0

Steel tendon broken or steel threads became loosened and completely rusted.

0

Steel tendon appeared dark brownish, the surface already appeared corral-like or lumpy or rusted

surface spread over 90%.

0.15

Steel tendon appeared dark brownish, the surface is rough, but not appearing corral-like or lumpy or

rusted surface is between 50~90%.

0.45

Steel tendon appeared light brownish, but the surface is smooth and shining or rusted surface is

between 10~50%.

0.75

Endoscopy

inspection

30

No anomaly presence or rusted surface is below 10%.

1.0

Detached, steel tendon broken or Tr=0.

0

Tr>1.2Tw or Tr

≦

0.2Tw

0.33

0.2Tw<Tr

≦

0.5Tw

0.67

0.5Tw<Tr

≦

0.8Tw

0.75

lift-off

test

45

0.8Tw<Tr

≦

1.2Tw

1.0

Single ground anchor capacity assessment(β)

Total score of anchor capacity assessment(α)

Remark: 1. If any of the items in categories 1,2,3,4 assessed a score of 0, such ground anchor shall be deemed as defective, and the total score of the

anchor shall be zero.

2. When a sloped terrain of which 1/3 of the ground anchors inspected has reach over 90% rusted surface under the examination of

endoscopy, but the lift-off test revealed remaining capacity falls into the range 0.8Tw<Tr

≦

1.2Tw, additional investigations in the field and

test data is recommended to determine whether the slope may have a tendency to slide.