2298

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

monopile and sand parameters, presumably including the

installation process. The rate of accumulation appears not to

depend markedly on the applied load magnitude. The analysis

in §6.2 suggests that the data might also fit with a natural

logarithm through to low numbers of cycles (

Δθ

N

/ θ

1

) = c.ln(N).

(Roesen et al 2013)

Figure 7. Monopile rotation versus number of cycles.

2.3.4

Caisson foundations

A centrifuge test of a caisson in sand is reported by Kim et al.

(2013). The caisson response to single combined load to failure

is measured and numerical analysis applied. The test details are

provided elsewhere and it is not clear whether the 1/70

th

scale

caisson was installed by suction during the centrifuge test or

before testing. Soil material from the proposed site is used to

model a planned prototype caisson foundation. The measured

response of the modelled prototype 15.5m diameter 10.5m long

caisson is shown on Figure 8 in terms of applied moment versus

rotation.

The authors report a parametric analysis using FLAC to

show the significant influence of the assumed elastic modulus

and cohesive strength parameters assumed for the soil.

(Kim et al 2013)

Figure 8. Measured moment-rotation for prototype caisson.

The offshore design standard DNV-OS-J101 (DNV, 2011)

requires structures to resist a 50 year design storm considering

both peak loads and the entire history of cyclic loading. It is

this latter requirement that is tackled by Versteele et al (2013)

for the case of caisson foundations in sand.

Because a full analysis of cyclic loading of caissons in sand

is not practically feasible with current numerical methods, the

authors develop an analysis to provide insight into the

competing processes of excess pore water pressure generation

and dissipation during the design storm. The analysis breaks

the storm into several packages of cyclic loading (magnitude,

number of cycles and time). The excess pore water pressure

generated at each point in the soil by the package of cyclic

loading is computed analytically and input into the numerical

analysis. The dissipation and redistribution of pore water

pressure during the time period is computed numerically. The

process is repeated for the next package of cyclic loading, and

so on.

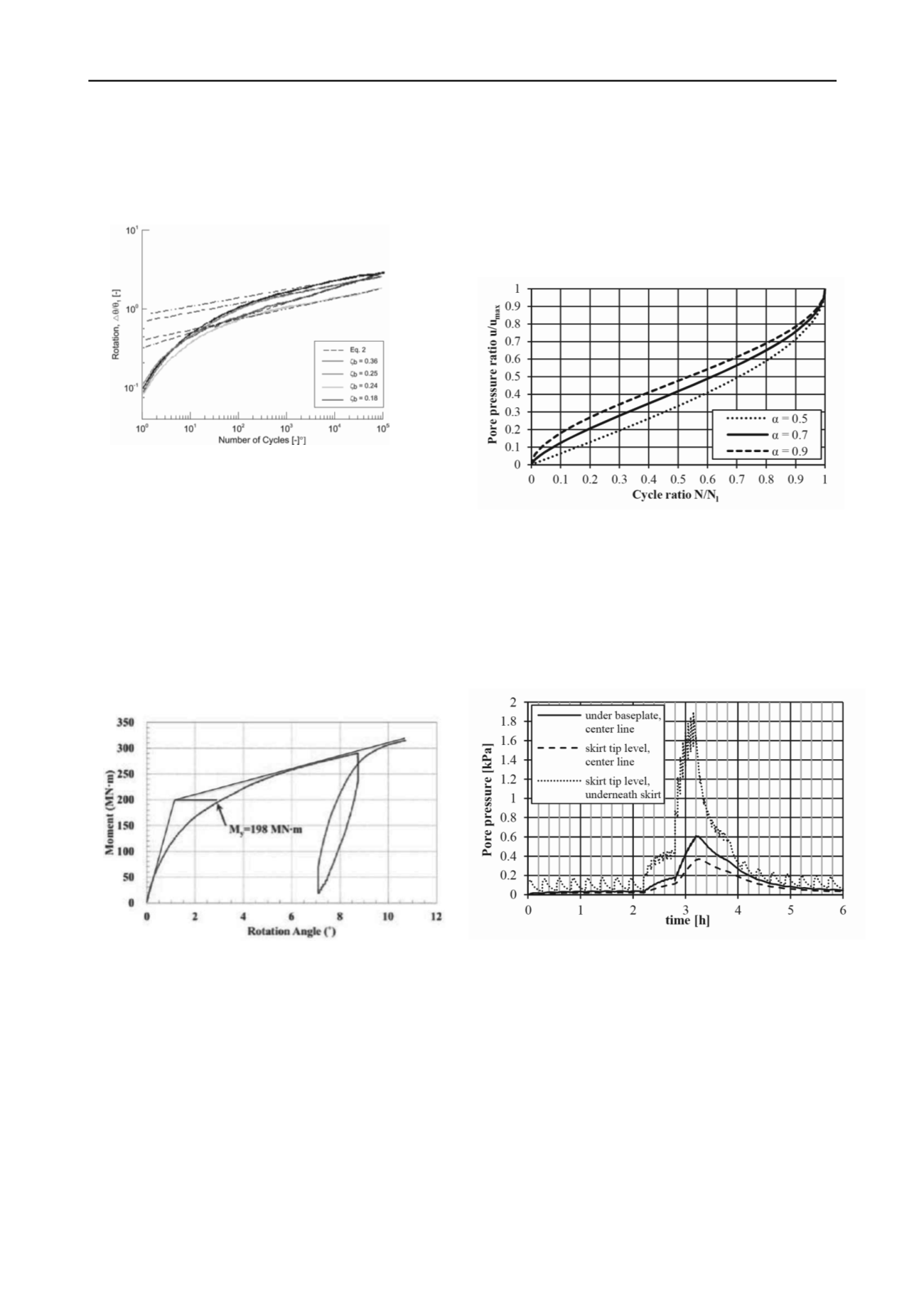

The analysis for pore pressure generation uses two relations

for the sand material. First the measured cyclic shear strength

versus number of cycles to liquefaction,

N

l

, from cyclic

laboratory tests; second an empirical formula linking pore water

pressure generation to number of load cycles, Figure 9.

Liquefaction occurs at

u/u

max

= 1 when

N/N

l

= 1.

(Versteele et al 2013)

Figure 9. Generation of excess pore water pressure.

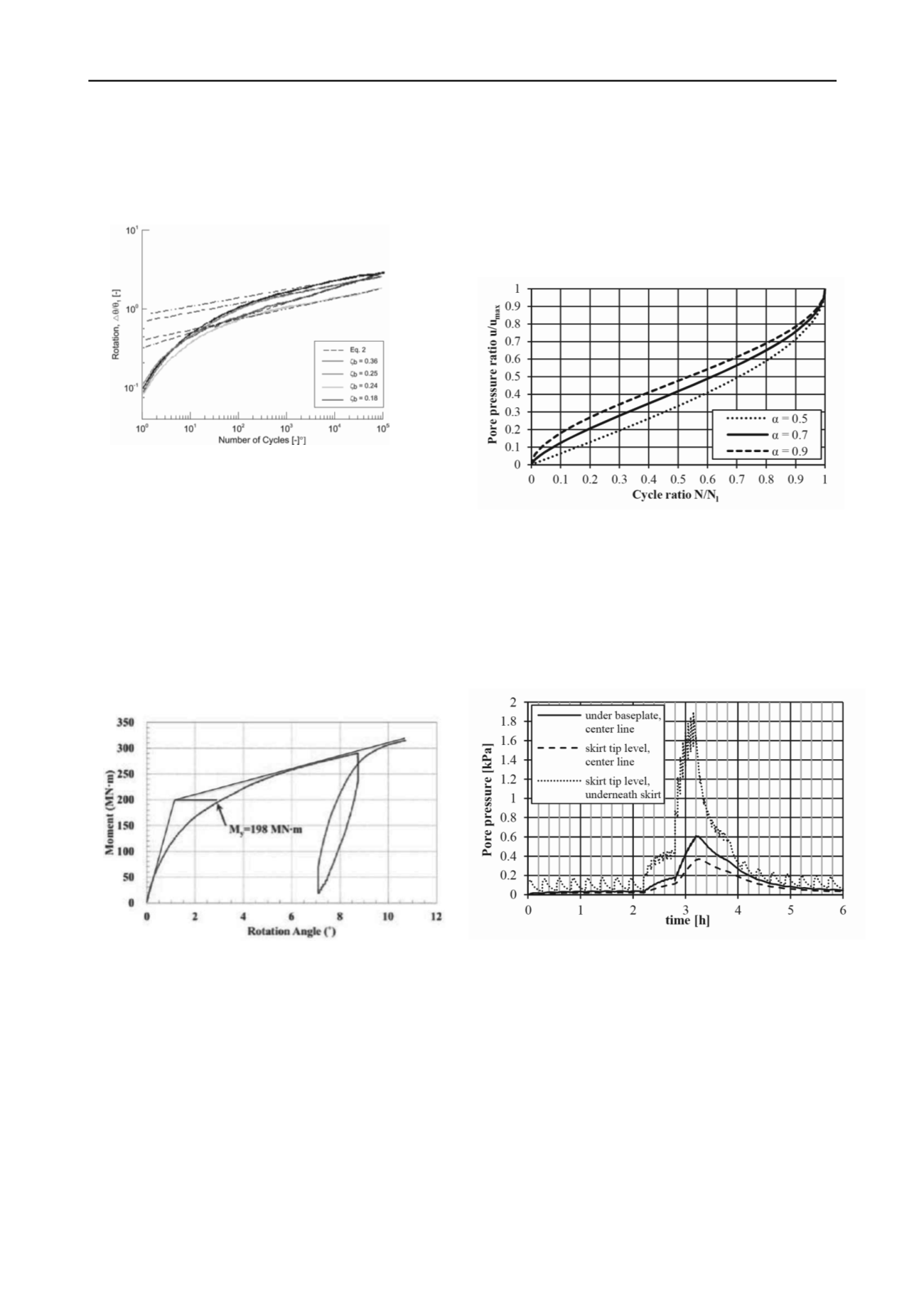

The results of a 3D analysis for a caisson foundation are

reported to illustrate the method, Figure 10. The 20m diameter

by 10m length caisson is subjected to a 6 hour design storm of

2160 waves. These are split for analysis into 5 individual load

packages. The direction of wind and wave loading is assumed

to be aligned. The results illustrate the asymmetric nature of

pore water pressure generation that has potential consequences

for possible differential settlement and tilting of the caisson.

(Versteele et al 2013)

Figure 10. Example of excess pore water pressure below a caisson.

Versteele et al

(2013)

conclude that the model is useful in

predicting areas beneath the caisson prone to the development

of excess pore pressure. However, the analysis does not predict

liquefaction behaviour or compute settlement, nor does it allow

for load redistribution in the caisson due to the changing

effective resistance in the soil during the design storm. There is

further development work to be done.

3 PIPELINES AND LARGE DISPLACEMENT.

A challenging feature for offshore pipelines is the large

displacement that can occur during installation and service.

Large displacement is particularly extreme for laying pipe on a

soft seabed. Large displacement also results from multiple

cycles of heat expansion and contraction of the operating

pipeline. This requires engineering design to avoid localized