2305

Technical Committee 209 /

Comité technique 209

design load are collinear) or sliding (incremental loading

direction collinear with the Horizontal component of the

reference design load). Another particular case included is that

of “plastic overturn”, a prescribed check for breakwater design

in Spanish regulations (Puertos del Estado, 2005) in which the

lever arm of the horizontal loading is maintained (i.e. the

incremental load is aligned with the the Horizontal and Moment

components of the reference load).

3.3

Example formulations

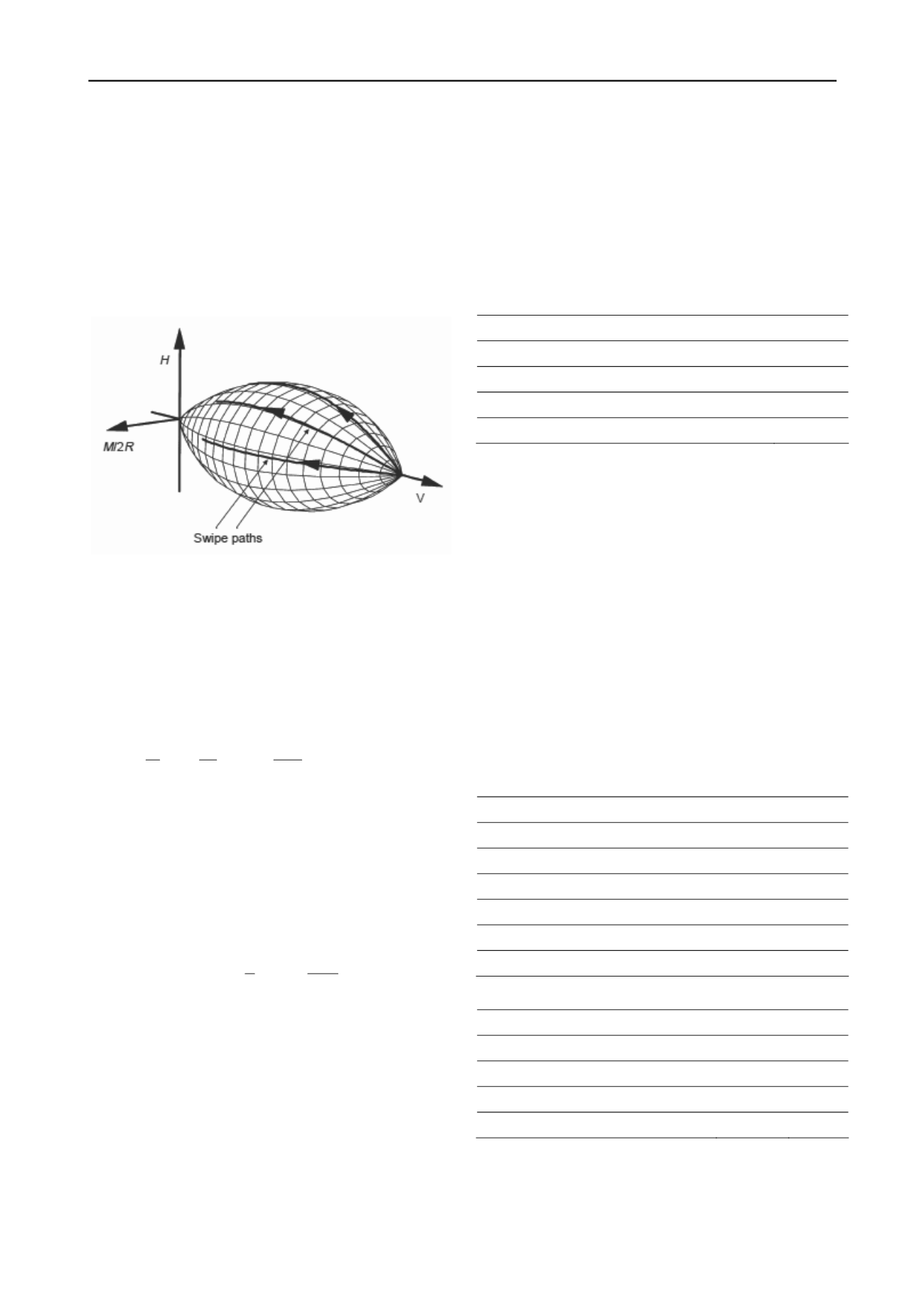

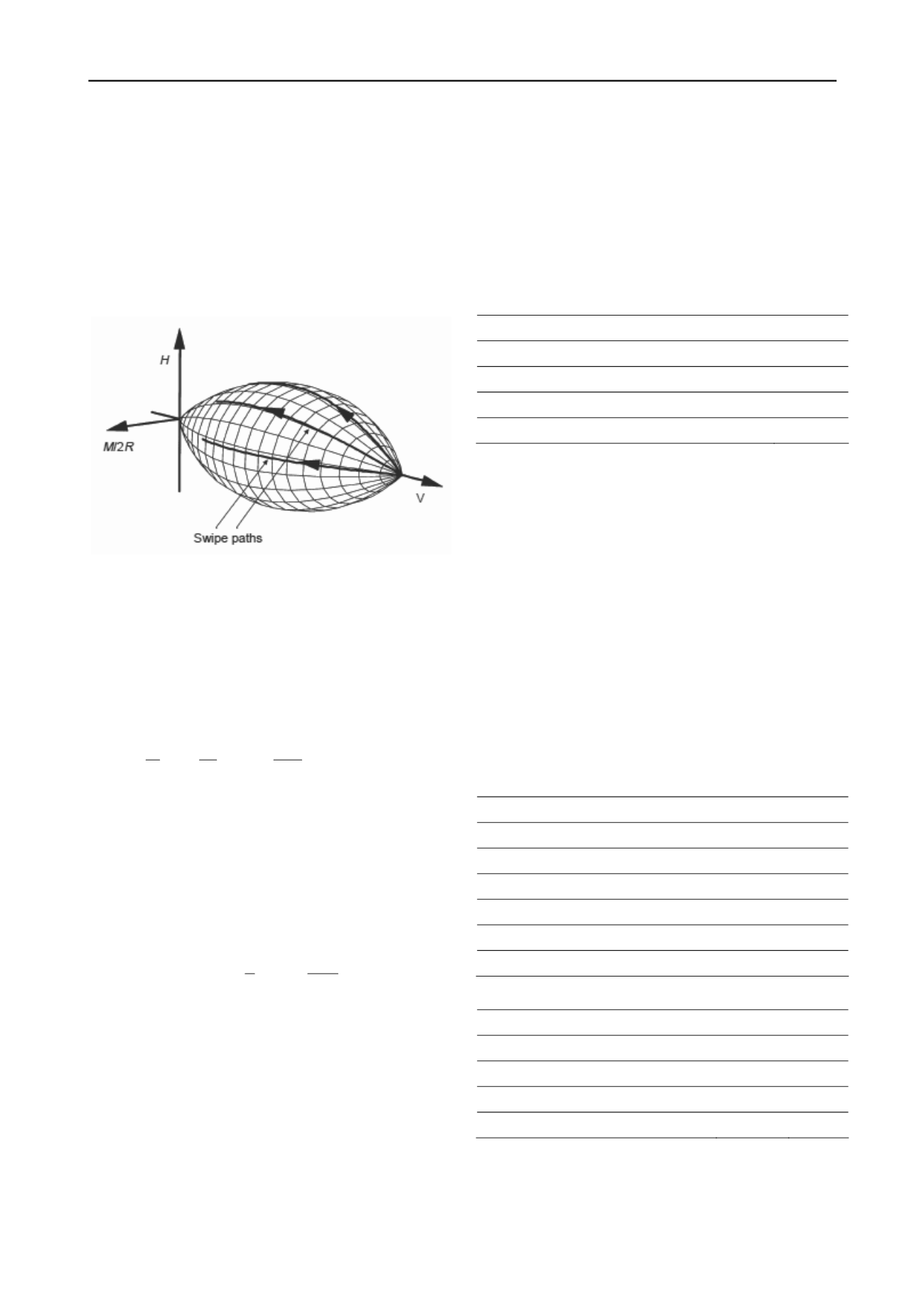

Figure 3 Failure envelope by Gottardi et al (1999)

There are many failure envelopes in the literature. For

foundations failing without drainage at the soil-foundation

interface Gourvenec & Randolph (2011) offer an excellent

review. For the example below a sand profile is assumed and

drained conditions are reasonable. In these circumstances a

convenient expression for a failure envelope is that proposed by

Gottardi et al. (1999) (Figure 3)

2

2

2

0

0

0 0

( , , )

2

(4 (1 )) 0

F V H M

h

m

hm

a

v v

h

m

h m

(3)

Where (a, h

0

, m

0

) are shape factors, empirically determined

as (-0.22, 0.12, 0.09) for quartzitic sand, and we use a non-

dimensional notation in which

v

= V/V

0,

h

= H/V

0,

m

= M/(DV

0

)

and D is the foundation diameter. The normalizing factor V

0

is

the maximum load (i.e. centered vertical) that the foundation

can sustain. Here that maximum load is computed assuming no

embedment and introducing the bearing capacity factor

N

from

Bolton & Lau (1993) into

2

0

1

2

4

D

V DN

(4)

It is worth noting that (a) it is relatively straightforward to

generalize expression (3) to more complex loading situations –

e.g. Lesny 2010- although the experimental base for adjusting

the parameters in those circumstances is somewhat scarce, (b)

that the shape of (3) above has proven rather resilient and very

similar expressions have been found to fit well other foundation

test results in materials like carbonate sand or even clay (Martin

& Houlsby, 2001), as long as the contact surface remains

drained. Of course the choice of V

0

would change according to

the material and foundation shape.

4 EXAMPLE APPLICATION

To illustrate the argument we propose an example, synthetic but

realistic. The case is developed using the characteristics of the

gravity base substructure built at Thornton Bank (Peire et al.

2009) and the design loading specified for a Baltic windfarm

development site, Kriegers Flak (Bulow et al, 2009). This

reference gives some basic characteristics for the OWT

superstructure (Table 1).

Table 1 Super-structure characteristics

Rated power

5 MW

Rotor diameter

126 m

Nacelle height above msl

90 m

Nacelle-rotor weight

4.1 MN

Tower weight

3 MN

The same reference also includes resultants from ambient loads

for a range of depths and load hypothesis (e.g. extreme, fatigue).

Using these data, Table 2 has been computed for a 30 m depth

case and extreme load scenario. It appears that, in this particular

case, 80% of the total horizontal thrust is due to sea action, but

this load is the source of less than 20% of the overturning

moment at foundation level. This might partly reflect the fact

that at that particular site sea current is relatively strong,

lowering the action line of sea forces.

These ambient loads should be combined with the OWT

selfweight. Using the Thornton Bank design like a template for

substructure shape, the relevant characteristics of that part of the

OWT are those listed in Table 3. As usual with gravity base

OWT, the dead weight of the substructure is significantly larger

than that of the superstructure. Combining all environmental

actions and structure selfweight the resultant load combination

acting at the foundation level is (H, V, M) = (10.1; 44.5; 284.3)

in MN and MNm. This will be the reference design load state in

this example.

Tabla 2 Ambient loading parameters

Parameter / load

Unit

Value

Total thrust, H

MN

10.1

Total overturning moment, M

MNm

284.3

Wind thrust, Hw

MN

2.03

Wind arm lever, bw

m

120

Sea thrust, Hs

MN

8.07

Sea arm lever, bs

m

5

Tabla 3 Thornton Bank type substructure characteristics

Parameter / load

Unit

Value

Base diameter

m

23,5

Concrete weight

MN

30

Fill weight

MN

38

Buoyant volume

m3

2965

From that reference state we probe the failure surface

alongside three different incremental loading paths. One will

correspond to a simultaneous and proportional increase of all

ambient actions (the “plastic overturn” case). The other two

hypothesis would correspond to increases of just one of the