2313

Technical Committee 209 /

Comité technique 209

5 RESULTS AND DISCUSSION

5.1 2D Analyses

The accuracy of the 2D FE model was verified by computing

the uniaxial vertical capacity and comparing with results

published in the literature. An interface factor at the

mudmat/soil interface

= 1 was assumed for this comparison.

A normalized vertical capacity V

ult

/s

uo

B = 10.45 was found.

This compares well with the analyses results published by

Salgado (2008) who found 10.42 using ABC program (Martin,

2004). When the interface factor is reduced to

= 0.5, the

vertical capacity V

ult

/s

uo

B reduces to 9.8.

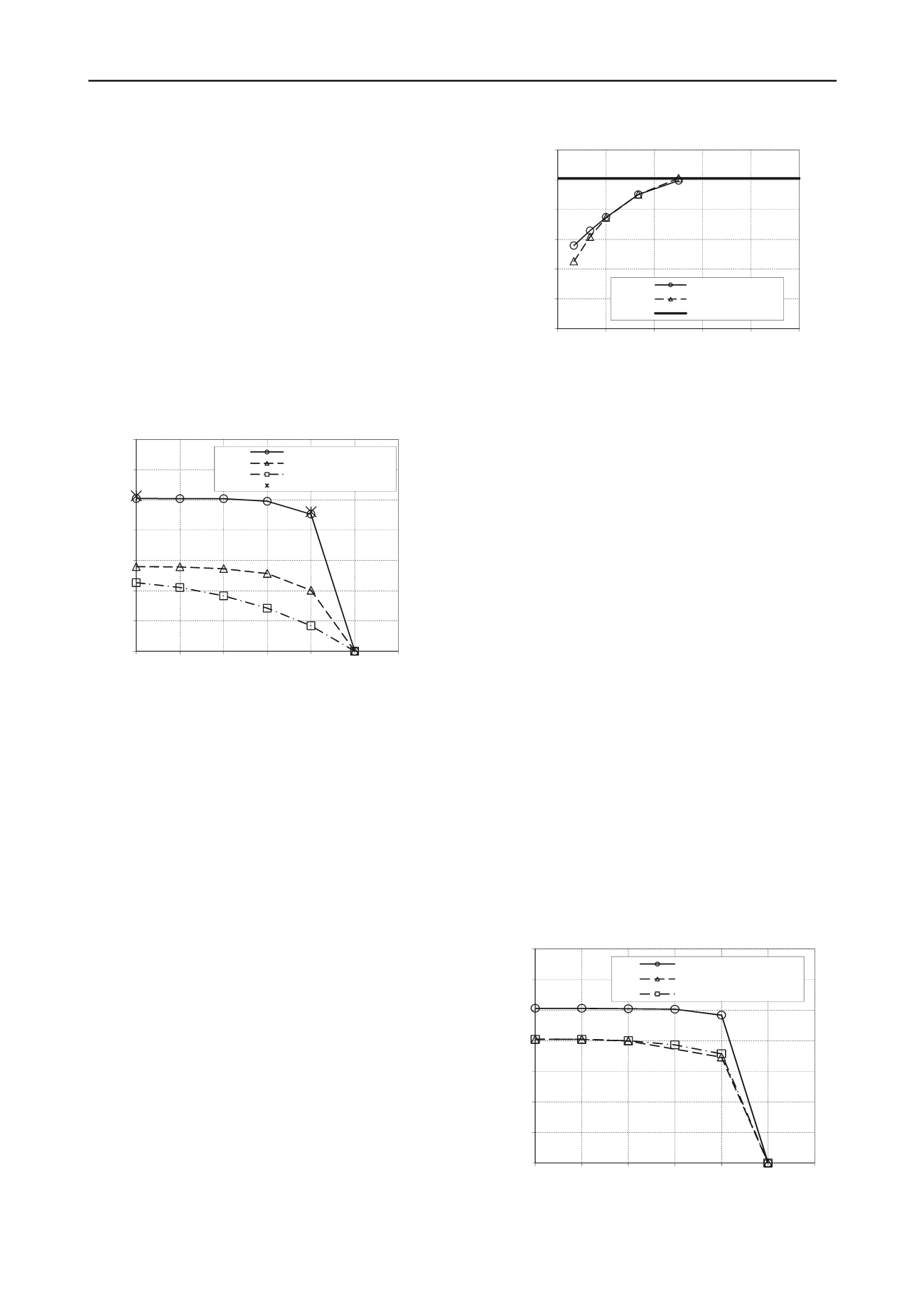

The MH failure envelope for the case without pug mark is

shown on Figure 3 assuming a vertical load V so that v = 0.4,

which is equivalent to a safety factor of 2.5 on the uniaxial

vertical capacity. The results are plotted in a non-dimensional

way: M/s

uo

B² versus H/s

uo

B. This case is for an inter-distance

d = 2 m (i.e. d/B = 0.07).

0

0.2

0.4

0.6

0.8

1

1.2

1.4

0

0.1

0.2

0.3

0.4

0.5

0.6

M/S

u0

B² [-]

H/S

u0

B [-]

v=0,4 - No pug mark

v=0,4 - Pug mark

v=0,71 - Pug mark

LS:GEO verification

Figure 3. Influence of pug mark on MH failure envelope

A few comparison runs were performed with Limitstate:Geo

v2 (Limistate, 2009). Limitstate:Geo is designed to analyze the

ultimate limit (or “collapse”) state for a wide variety of

geotechnical problems. The current version is however limited

to 2D plane strain analyses. The ultimate limit state is

determined using the Discontinuity Layout Optimization (DLO)

algorithm (Smith & Gilbert, 2007). The agreement with the FE

results is found to be excellent.

The effect of the pug mark on the MH failure envelope is

significant. The normalized uniaxial vertical capacity V

ult

/s

uo

B

is reduced to 5.5 leading to a mobilisation ratio v = 0.71 instead

of 0.4 (i.e. a safety factor of 1.4 instead of 2.5). The moment

capacity is reduced by 55% to 80% depending on the applied

horizontal load.

The inter-distance between the mudmat and the pug mark

was then progressively increased and results are presented on

Figure 4. The maximum moment capacity increases

progressively with the inter-distance towards the capacity

obtained for the case without a pug mark. From an inter-

distance d/B = 0.2, the difference in mobilisation ratio of the

vertical capacity does not affect the maximum moment capacity

and, at an inter-distance d/B = 0.5, the pug mark has no effect at

all.

0.0

0.2

0.4

0.6

0.8

1.0

1.2

0

0.2

0.4

0.6

0.8

1

M/S

u0

B² [-]

Inter-distance d/B [-]

V=0.4Vult - 2D

V=V0 - 2D

No pugmark

Figure 4. Influence of pugmark / mudmat inter-distance on maximum

moment capacity – 2D analyses

5.2 3D Analyses

The accuracy of the 3D FE model was also checked by

computing the uniaxial vertical capacity for a square footing

resting on soft clay, with s

u

constant with depth and

= 1, and

comparing with available literature results. A normalized

vertical capacity V

ult

/s

uo

B² = 5.96 was found. This compares

well with the results published by Gourvenec et al. (2006) who

found 6.02. When the interface factor is reduced to

= 0.5 and

s

u

increases with depth (as defined in Section 2), the vertical

capacity V

ult

/s

uo

B² is about 9.1, which is slightly lower that the

2D plane strain capacity.

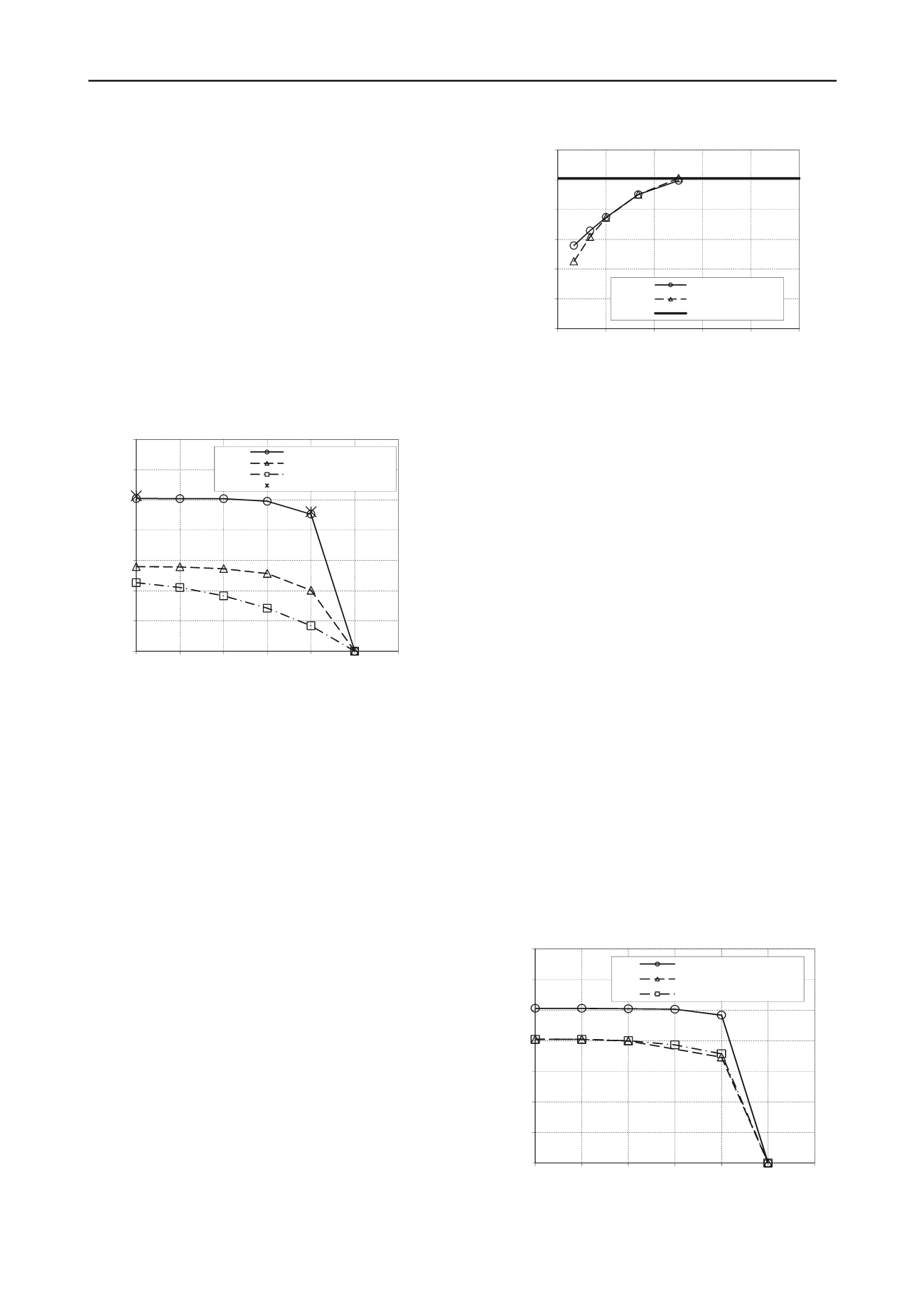

Similarly to the 2D plane strain FE analyses, the MH failure

envelope for the case without a pug mark assumes a vertical

load V so that v = 0.4. As discussed above and shown on

Figure 1, the 3D analyses consider two positions for the pug

mark: along the width and at the corner of the mudmat. The

results are plotted on Figures 5 and 6 for the first and second

positions, respectively, using the following non-dimensional

groups: M/s

uo

B³ and H/s

uo

B². This case is for an inter-distance

d = 2 m (i.e. d/B = 0.07). The moment capacity is not affected

for small mobilisation ratios of the horizontal capacity.

However, when H/s

uo

B approaches 0.5, the failure mechanism

switches rapidly from a general shear mechanism to a sliding

mechanism.

For the first position (along the width), the effect of the pug

mark on the MH failure envelope is noticeable but not as

significant as for the 2D plane strain simulations. The

normalized uniaxial vertical capacity V

ult

/s

uo

B² is reduced to

only 8.4 leading to a mobilisation ratio v = 0.44 instead of 0.4

(i.e. a safety factor of 2.29). The moment capacity is reduced by

20% to 28% depending on the applied horizontal load. There is

very little difference in the results between a vertical

mobilisation factor of 0.4 and 0.44 (Figure 5).

0.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

0

0.1

0.2

0.3

0.4

0.5

0.6

M/S

u0

B³ [-]

H/S

u0

B² [-]

v=0,4 - No pug mark - 3D

v=0,44 - Pug Mark - 3D

v=0,4 - Pug Mark - 3D

²

Figure 5. Influence of pug mark on MH failure envelope – Position 1

(along width of mudmat)