2321

Technical Committee 209 /

Comité technique 209

1.3

Project Construction Phase

During the construction phase, geotechnical activity is

typically limited to quality assurance testing which serves to

confirm and ensure that the design assumptions remain valid.

This is the phase where risks missed during the earlier phases

may become apparent with the potential for project cost

overruns.

Rarely would geotechnical input in this phase result in cost

savings. However,

value engineering

where the balance of plant

(BOP) contractor is provided an opportunity to redesign is

becoming more popular. Value engineering often occurs shortly

before construction or as the BOP contractor is mobilizing to

construct the project. Ironically, the likely reason for value

engineering is the tendency of the original designer to err on the

conservative side because of compressed schedules and/or lack

of substantive geotechnical basis of design at the end of the

development phase, creating opportunities for the BOP

contractor to cut costs at the last minute.

1.4

Summary of Current and Proposed Practice

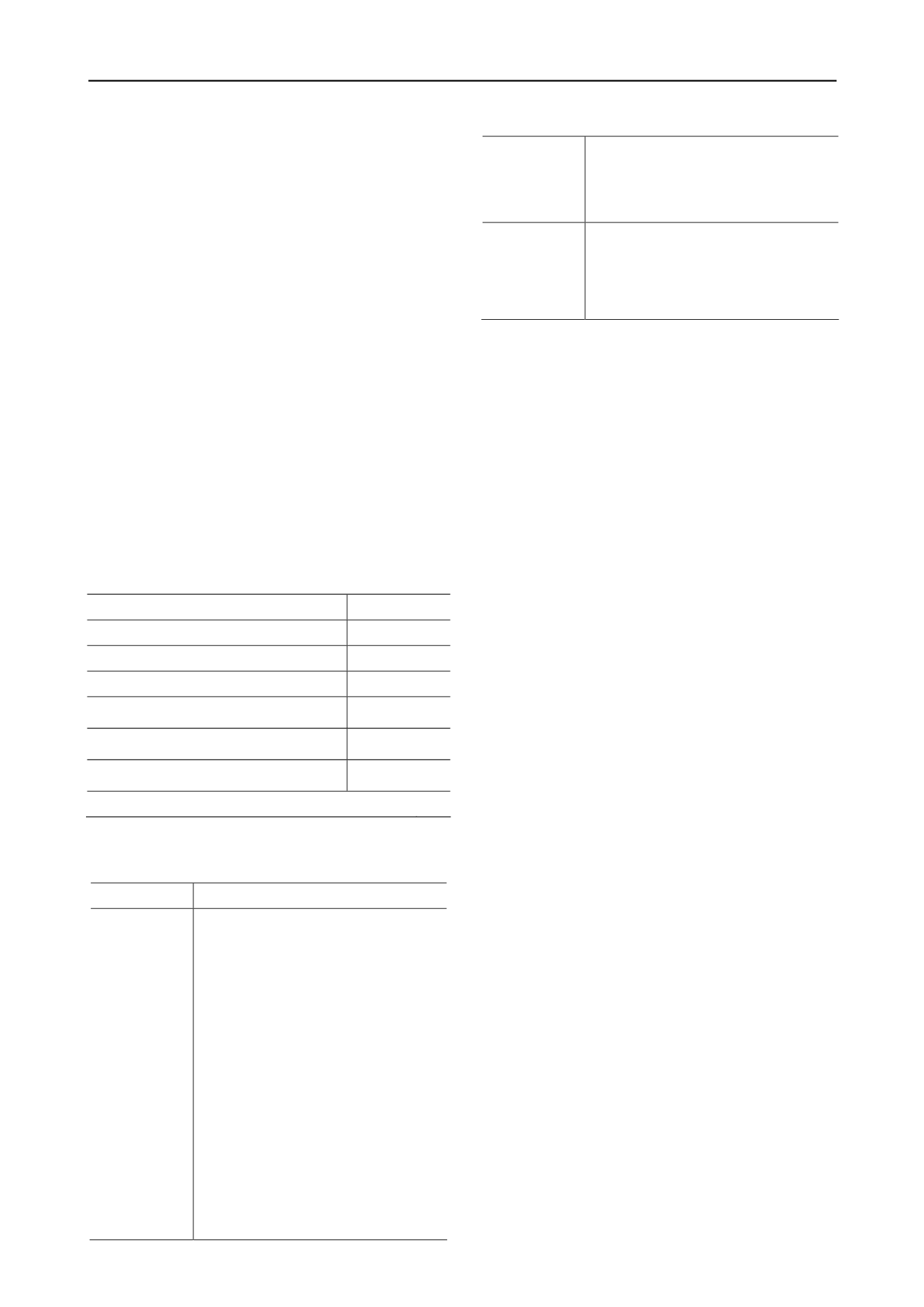

Table 2 shows a summary of current and proposed practice.

The essence of the proposed redistribution of the geotechnical

exploration effort is to advance the geophysical survey and the

preliminary investigation to the development phase (P1). Details

of the geotechnical activities for the proposed redistribution are

shown in Table 3.

Table 2. Common and proposed geotechnical effort.

Common

Proposed

Phase

P1 P2 P3 P1 P2 P3

Desk study

X

X

Geophysical survey

X

X

Preliminary investigation

X

X

Full investigation

X

X

Assurance & validation

X

X

Phases: P1 = Development, P2 = Design, P3 = Construction

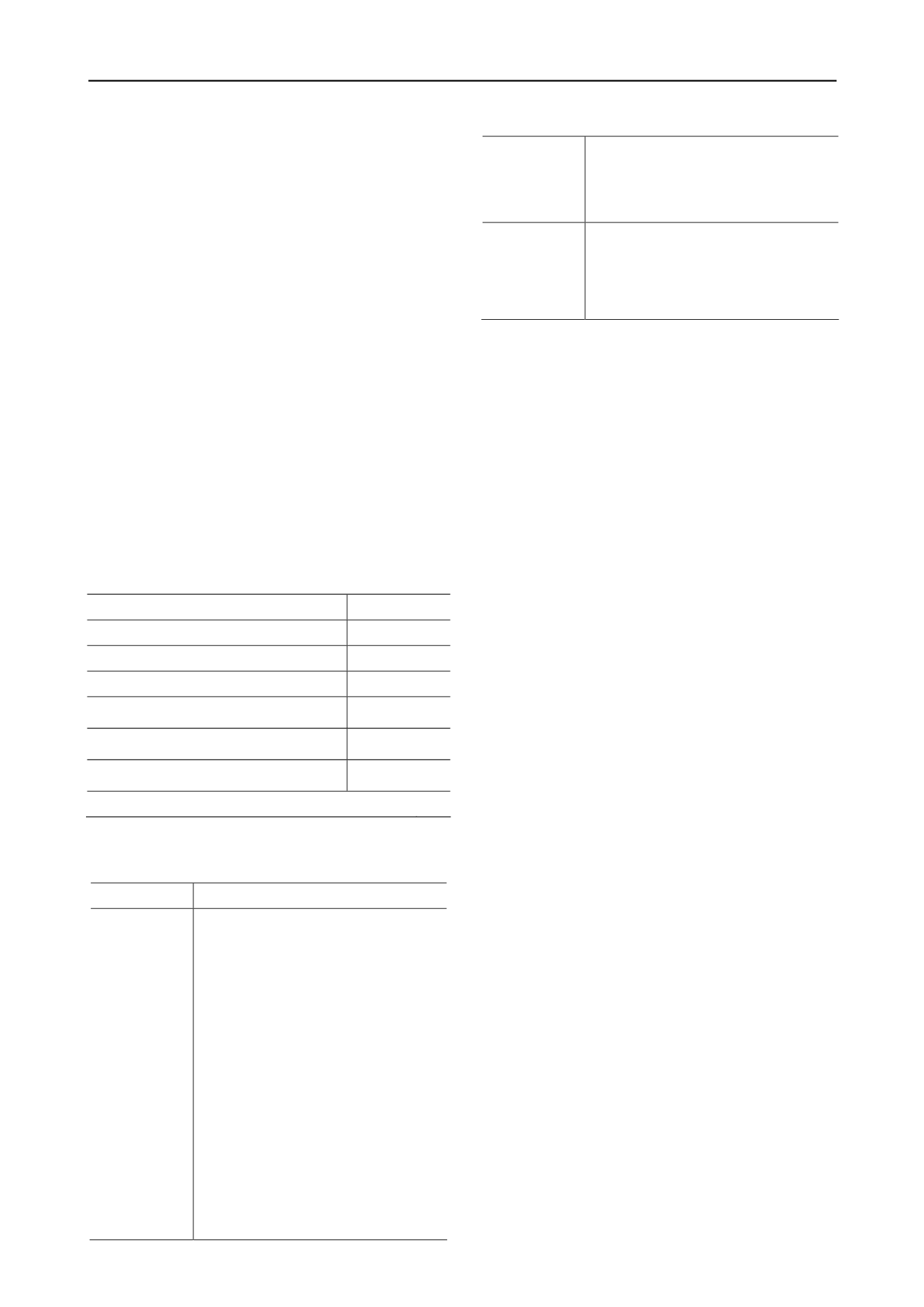

Table 3. Wind farm realization phases and proposed geotechnical

ctivities.

a

Phase

Proposed minimum geotechnical activities

Development

Desk study:

o

Often required for permitting but

can be useful in planning

preliminary investigation

Geophysical Survey

o

All turbine locations except

possibly sites where rock is at the

surface

o

Useful for micrositing

Preliminary Investigation

o

Drilling at a subset of turbine

locations distributed strategically to

capture maximum variability

o

Excavation pits along potential

access road alignment

o

Electrical and thermal resistivity

testing

o

Limited laboratory testing

Design

Full Investigation

o

Drilling at all turbine locations

o

Extensive laboratory testing

o

Fill all gaps to form design basis

Construction

Construction QA/QC

o

Confirm validity of design

assumptions

o

Ensure compliance with design

requirements

2 SOURCES OF UNCERTAINITY

Wind energy projects differ from most traditional projects in

that they cover large terrains. Wind turbines are typically placed

5 to 10 rotor diameters apart to optimize energy extraction

(Denholm et al. 2009). Nowadays, typical rotor diameter for

large wind turbine generators is around 120 meters, signifying

turbine spacing of 0.5 to 1 kilometer just for energy extraction

efficiency. Therefore, wind turbines are too far apart to

consider any relationship between ground conditions from one

turbine location to another. This is separate from regional or

larger scale characteristics which may be applicable to the

project area or portions of it, such as those related to different

geologic settings or terrains. Turbine structures themselves are

also unique due to the nature of loading they impart to

foundations and supporting soils in terms of type, magnitude

and variation. Thus, in addition to increased uncertainty due to

essentially independent conditions at turbine locations, these

projects also require parameters unique to these structures such

as those needed to ensure adequate foundation stiffness.

Generally, there are three main sources of uncertainty in a

geotechnical design property: i) inherent soil variability, ii)

measurement error, and iii) transformation error (see Baecher

and Christian 2003, Phoon and Kulhawy 1999). Often, a design

parameter is not measured directly in-situ or in a laboratory test

but is calculated based on other measured properties. Two of the

above sources (inherent variability and measurement error) are

associated with the measured property. The third source is

associated with uncertainty in the selected transformation

model, i.e., the empirical or theoretical relationship used to

calculate the design property from the measured properties.

Point estimates, as well as spatial variability of various shear

strength, mechanical and index properties, are available in the

literature (e.g., Lee et al. 1983). This information can be used to

select the test methods that result in lowest variability

depending on the soil type. In this section, uncertainty sources

are discussed in more detail as they relate to wind energy

projects.

2.1

Uncertainty Due to Inherent Soil Variability

Inherent soil variability is related to the natural geologic

processes that produced the soil and should not include the

influence of deterministic trends (e.g., trends due to depth),

mixing of soils from different geologic units, or measurement

errors. In the case of wind projects, inherent variability should

be considered at each individual turbine location.

Another source of uncertainty is related to spatial variability

extending vertically and horizontally to dimensions of

influence. Uncertainty related to spatial variability is affected by

the scale of fluctuation or correlation distance which is an

important statistical parameter loosely defined as the distance

within which the values of a given parameter are significantly

correlated (Fenton and Griffiths 2008). Due to the often layered

nature of soils, the correlation distance is typically shorter in the

vertical direction than in the horizontal direction. Engineering

design practice, including that within the wind energy industry,

considers single (or point) variables to represent properties of an