2286

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

2 INSPECTION ITEMS AND PROCEDURE

Ground anchoring inspection and assessment is aimed to

analyze and understand the performance of existing anchors and

the impact to the site and its surrounding.

2.1

Inspection items

Currently there are some initial inspection items including:

exterior inspection, anchor head inspection, endoscopy

inspection and Lift-off test, the four major itemswill be

explained in detail later.

2.2

Inspection procedure

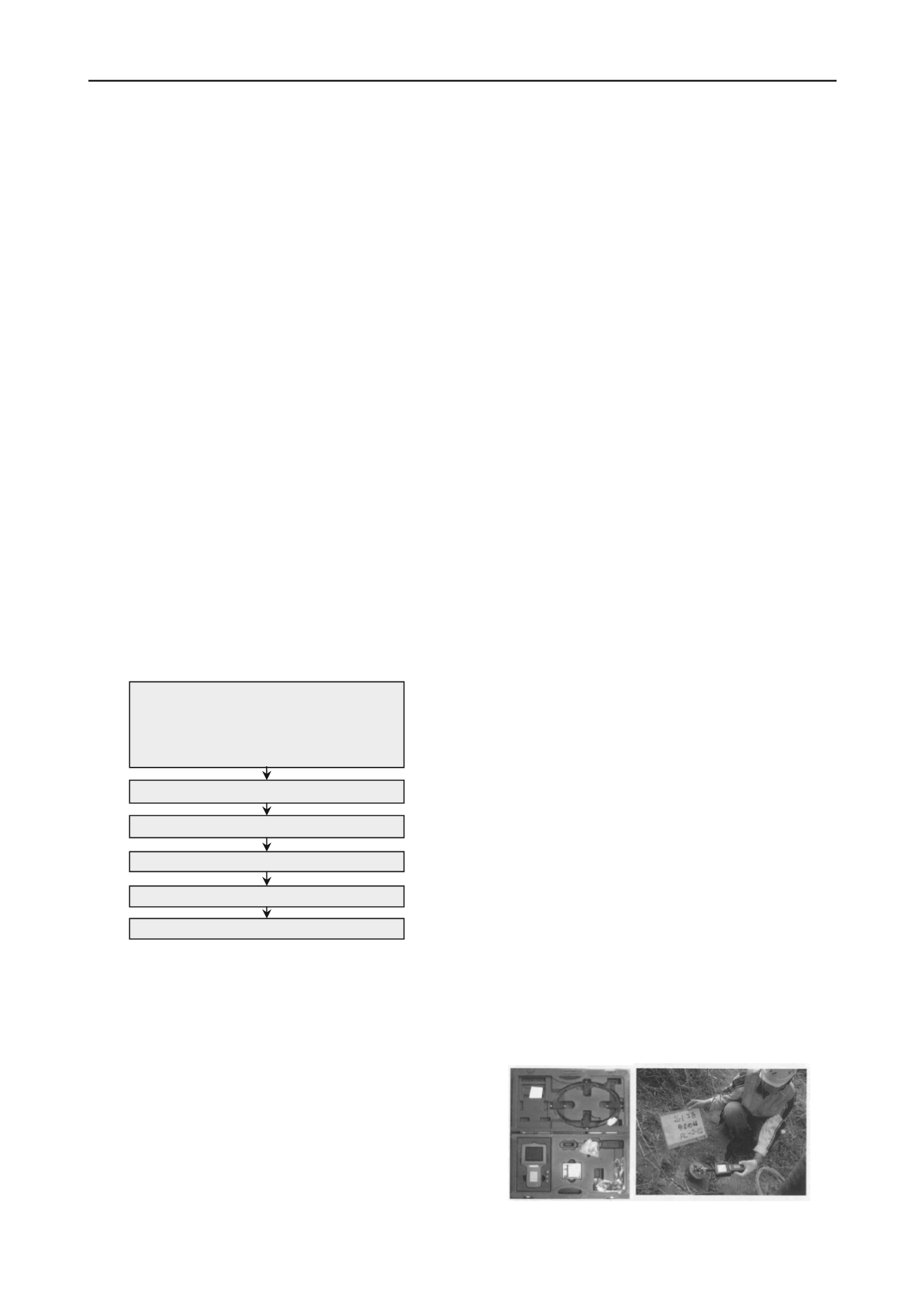

Inspection procedure is as indicated in

Figure 2

. First gather

basic data from all sloped terrains for ground anchor index, then

remove all outgrowth on the slope, and check the entire ground

anchors for outside appearance, pressure bearing integrity and

water seepage status. According to the gathered data and

inspection results, select the most typical anchor in

characteristics of all achors, remove the concrete casing to

examine the anchor head and steel tendon closely, and record

findings. After examining the anchor, use the findings to select

partial ground anchors for endoscopy inspection to exam steel

tendon corrosion and proceed with Lift-off Test, in order to

understand the existing ground anchor Residual load(Tr).

Lastly, based on sloped terrain basic data and findings of

various test results, evaluate in totality the ground anchors

current capacity. If ground anchor capacities no longer meet the

requirement of original specifications or there are other

anomalies present which render the anchors inappropriate for

continuing usage, then a proposal is required to improve or

remediate the situation, including refurbishment, remedy,

reinforcement or reconstruction as required.

Figure 2. Ground anchor capacity assessment flowchart

3 CAPACITY INSPECTION METHOD

Various inspection category results can be used to provide as

the basis for evaluating the capacity of anchors, summary of

each categories is as follows:

3.1

Exterior inspection

Prior to knocking off the ground anchor concrete protected

seats, obtain as-built drawings to mark off each and every

anchors with numeric identifications. Visually inspect,

investigate and record all anchor protected seats and load

bearing structure system conditions. Visual inspection should

emphasize on 1) anchor head protected seat hammer knocking

test and the quality of sound whether solid or hollow, 2)

visually inspect exterior of anchor protected seat for any

damages, 3) between anchor head and load bearing structure,

look for any sign of separation, rotation, or even detachment, 4)

Whether subsoil below shows sign of cave-in for the load

bearing structure and 5) anchor head proximity has sign of

efflorescence or ground water seepage, and all visual inspection

should be carefully documented.

3.2

Anchor head assembly inspection

Anchor head assembly includes locking mechanism(wedges and

screw head), load bearing plate and angle plate, as such parts

tend to have anomalies. When inspecting anchor head

assembly, carefully select a representative anchor head, after the

removal of concrete protected seat, visually inspect the

corrosive state of the anchor heads. After removal of anchor

head protected seat the following category of items need to be

recorded: load bearing plate dimension, angle plate dimension,

load bearing plate angle, anchor head dimension, steel tendon

style and remaining length data.

At this stage visual inspection should emphasize on 1)

anchor head wedges and steel tendon corrosion, 2) anchor head

assembly and water seepage condition and 3) steel tendon

interior shortening, and all inspection should be recorded in

detail.

3.3

Endoscopy inspection

Endoscopy can be used to inspect the backside of anchor head

and free section of steel tendon, to determine whether the steel

tendon is corroded, broken or free section has water inside.

Entire inspection process should be video recorded to allow

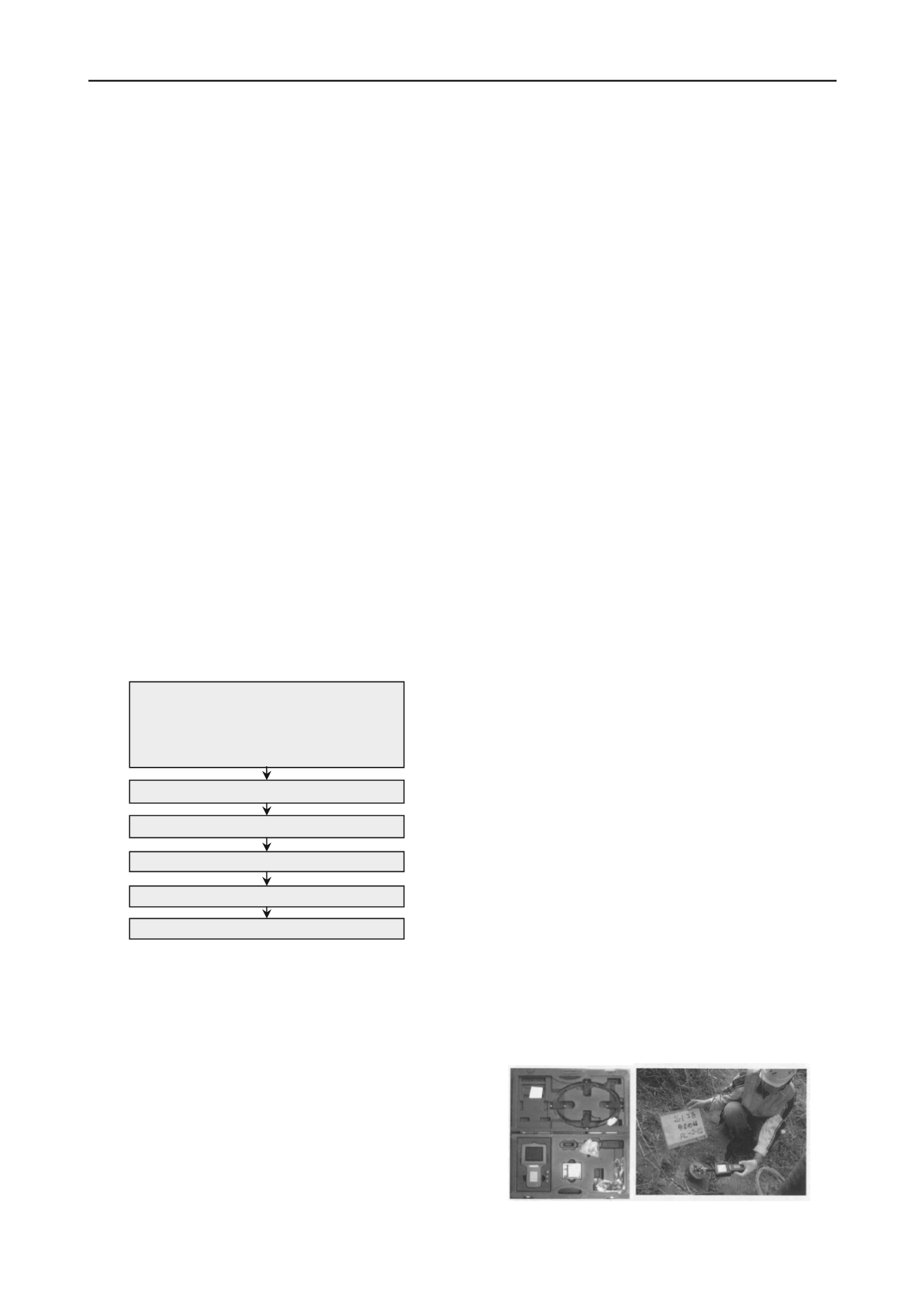

further inspection and study back in the lab. The equipment

used is as shown in

Figure 3

.

Besides inspecting steel tendon status, this stage should

measure the steel tendon length of free section. The measuring

technique is to use a stainless steel rod to insert into the anchor

free section portion until the rod can not be inserted further, as

Figure 4

indicated. Then record the length of the rod which was

inserted, as such length can be taken as the exposed section

length.

Basic data gathering

•Construction plan or as-built plan

•Disaster history

•Geological Report

•Construction records

�

Endoscopy inspection should emphasis on 1)steel tendon

corrosion level, 2)steel threads loosened condition, 3) free-

section concrete condition, 4) any concrete casting pipes and 5)

interior moisture level or any water seepage, all inspection

processes should be done carefully and in detail.

Exterior inspection

Anchor head assembly inspection

3.4

Lift-off test

After locking in load bearing of ground anchors, it’s possible

that due to creep at the bond end, wedges not properly function

which would reduce or increase the loading capacities. To

measure the change of loading capacities after lock-in, typical

lift-off test is conducted, as shown in

Figure 5.

Lift-off test is

aimed at finding the remaining load capacity of anchor(Tr), and

the reason being when tensile load is greater than the anchor

remaining capacty, anchor will demonstrate obvious

displacement increase, from which can be taken to evaluate the

remaining capacity of ground anchors, as shown in a standard

test curve in

Figure 6

. Ground anchor residual load(Tr) divided

by ground anchor original designed load capacity (Tw) is the

remaining load capacity ratio.

Endoscopy inspection

Lift-off test

Anchor capacity assessment

Figure 3. Equipment installation and operation