2062

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

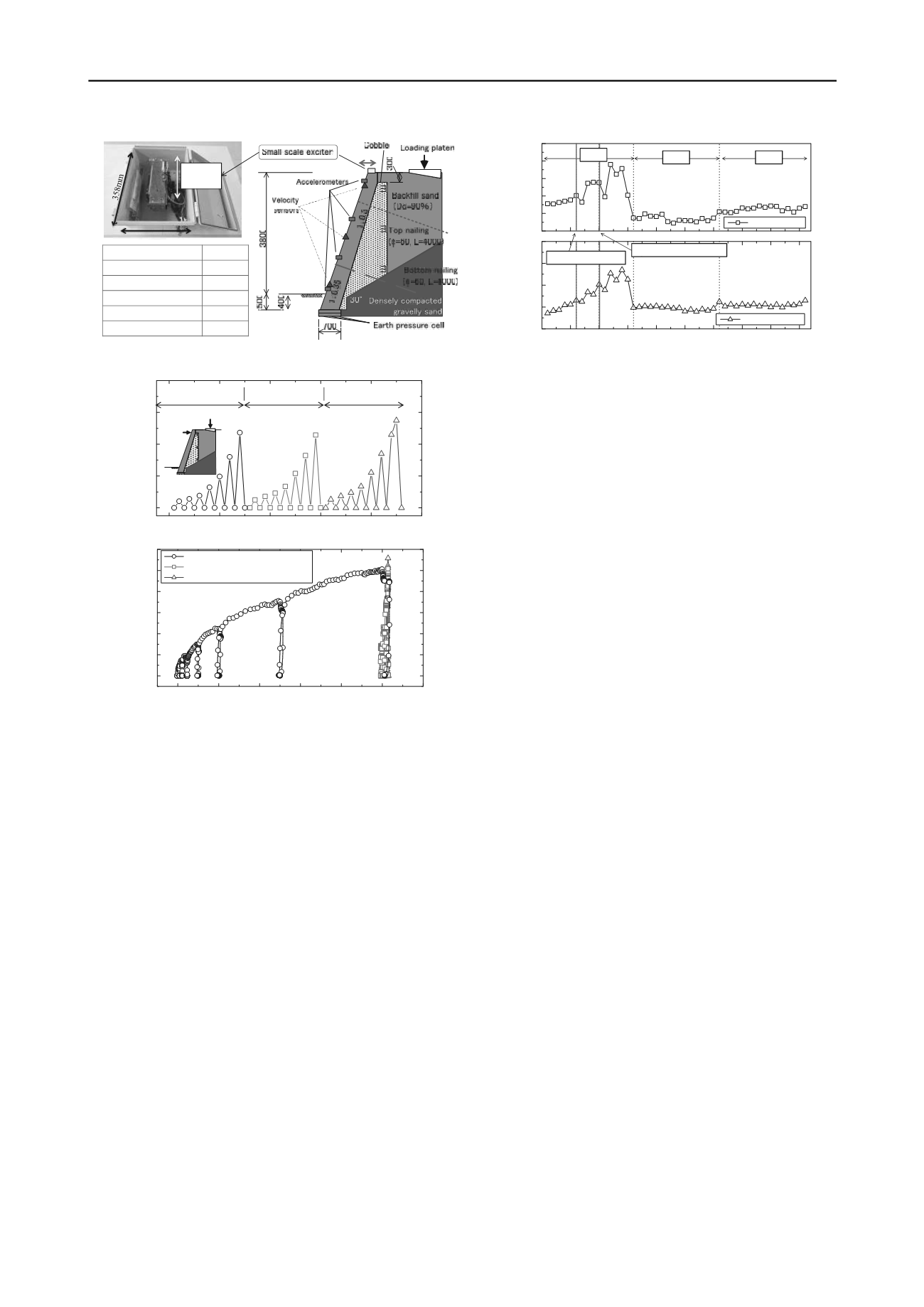

of loading process (Case 3). The loading and unloading

processes in each case were summarized in Figure 8.

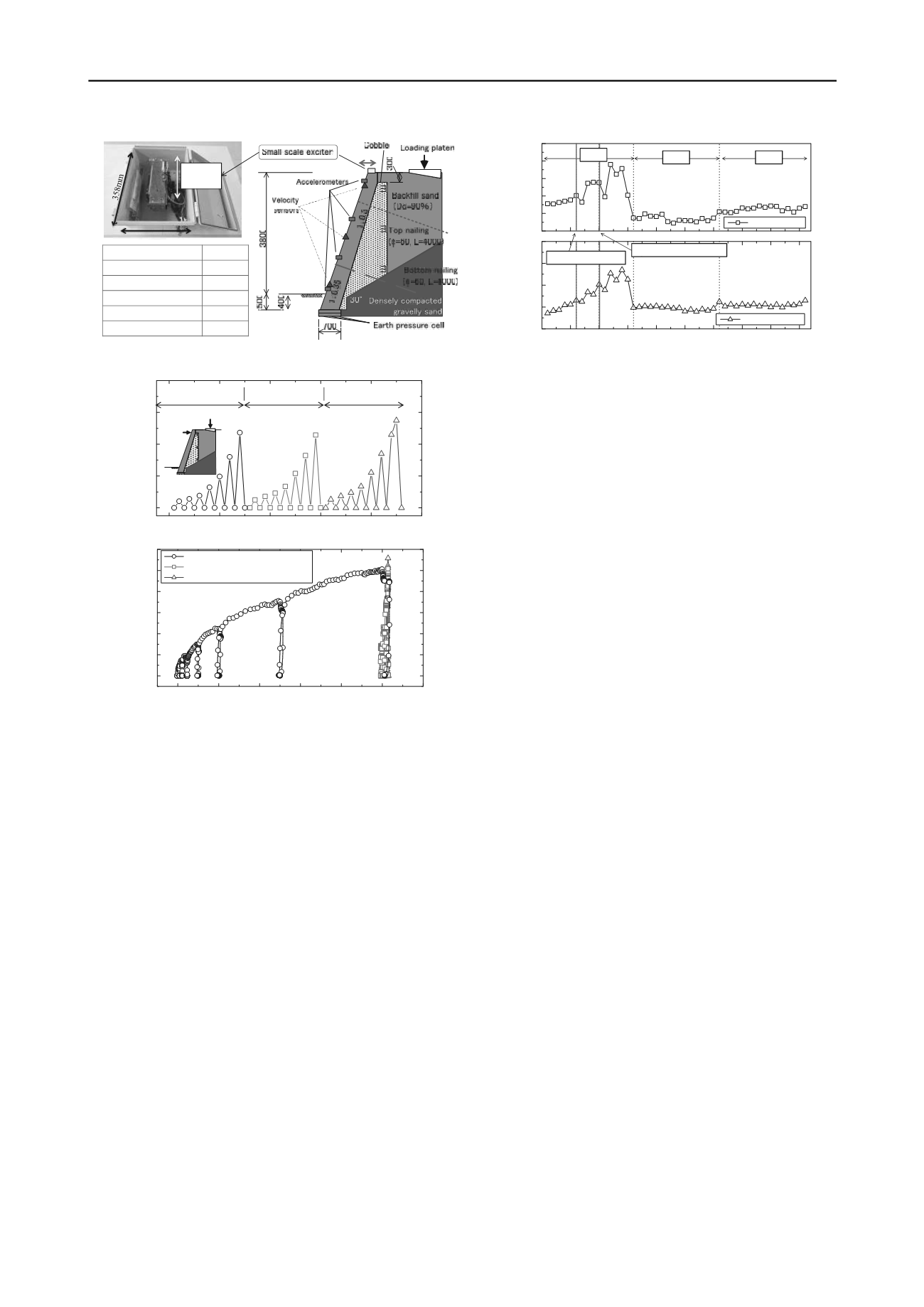

At every loading and unloading process, sets of percussion

test with a set of velocity sencers and vibration tests using the

developed small scale exciter with a set of accelerometers were

conducted so as to investigate into the difference of vibration

characterestics obtained from each test. Vibration test was

conducted by applying the sinusoidal sweep excitation to the

retaining wall model by the small scale exciter fixed at the top

of the retaining wall, while the constant amplitude of 1000 gals

with frequency range of 3 to 100 Hz and sweeping rate of 3

Hz/sec were adopted as the test condition.

Figure 8 also shows load-displacement relationships obtaied

from the loadcell installed at the hydraulic jack and

displacement transducer at the top of the retaining wall. As

clearly shown in Figure 8, the increment of the wall top

displacement was drastically reduced by adding the soil nailing

although the same amplitude of loading processes were applied

to the wall. Displacement increment during a set of loading and

unloading processes in Cases 1, 2 and 3 were 50mm, 1.0mm

and 0.5 mm respectively.

Figure 9 shows relationships between the number of step

and the results from the percussion test and vibration test, while

the values of spectrum area of frequency range of 3 to 40 Hz

were plotted in the virtical axes. It should be empasized that the

spectrum area evaluated from the pecussion test results Sa[p]

has the dimension of velocity (cm/sec) because it was evaluated

from the integration of the relationships between the Fourier

’

s

amplitude of velocity (cm/sec*sec) computed from records of

the velocity sensor at the top of the wall and the freauency

(1/sec). On the other hand, the spectrum area calculated from

the vibration testing Sa[v] did not have any dimensions because

it was evaluated from the transfer function of the top

accelerometer against the input acceleration.

It was found from Figure 9 that the values of Sa[p] and Sa[v]

increased with the number of step. Moreover, the effect of the

nailing could be also detected as the reduction of the values of

Sa[p] and Sa[v] in Cases 2 and 3 as compared with Case 1. The

diffrence between Sa[p] and Sa[v] could be found especially in

loading and unloading process. The values of Sa[v] increased in

the loading process and reduced in the unloading process, which

indicated that the spectram area Sa[v] based condition rating

using the vibration testing with the small scale exciter could

detect a minor change of the stability of the retaining wall. The

value of Sa[p], however, could not detect a minor change during

single loading and unloading process, which was possibly

because the input force could not be kept constant. It was found

from the results of the site tests and prototype scale loading test

that the percussion test and the vibration testing could be

applicable, while vibration testing could detect a minor change

of the stability of the retaining wall.

5 SUMMARY

It was attempted in this study to develop a inspection method of

the existing retaining wall. It was found from the preliminary

survey on the current state of Japanese railway retaining wall

that condition rating of the leaning and the ashlars wall are

important because of their huge amount of existing structures.

Based on the site test and prototype scale loading test, it was

found that the percussion test and vibration test using the

spectrum as an index could be applicable for the condition

rating of existing retaining walls.

6 REFERENCES

Oyado, M., Miyashita, M., Ueda, S. and Sakairi, A., An at-tempt of

rationalizatiojn for maintenance of railway structure using

supporting system,

Proc. of 5th International conference for bridge

maintenance, Safety and Management

, pp.3459-3466, 2010.

Railway Technical Research Institute, Maintenance Standards for

Railway structures, 2007.

Nishimura A., Okumura, F. and Tanamura S., Integrity Judg-ment of

Railway Bridges by Percussion Tests for Structure Response,

Quarterly Report of RTRI

, Vol. 29, No.4, pp.184-189., 1988.

S. Nakajima, M. Shinoda, K. Abe, T. Mai and T. Ehara: Study on

inspection method for railway existing retaining walls using

vibration testing,

IS-Hokkaido 2012: 2nd international conference

on transportation geotechnics

, 2012.

Shinoda, M., Nakajima, S., Abe, K., Tetsuo M. and Ehara, T.:

Development of nondestructive inspection method of railway

bridge substuructures with small vibration exciter,

Proc of the

International workshop on ICT in Geo-Engineering (ICTGE2012)

,

17-18 May 2012.

0.10

0.20

0.30

0.40

0.50

0.60

0 5 10 15 20 25 30 35 40 45

0.05

0.10

0.15

0.20

0.25

Percussion test

Spectrum area, Sa[p] (cm/s)

Vibration testing

Number of step

Spectrum area, Sa[v]

Case2

Case3

Case1

Lift up at heel of base

Local failure at toe of base

Figure 9. Cross section of model (unit in mm)

336mm

Moving

direction

Rated sine force (N)

98

Max. displacement (mm)

80

Max. velocity (cm/s)

74.8

Max. acceleration (m/s

2

)

14

Frequency range (Hz)

3-200

Shipping weight (N)

147

Figure 7. Cross section of model and outline of developed exciter

(unit in mm)

0

10

20

30

40

50

0

200

400

600

800

Load(kN)

Number of steps

Load

Horizontal

disp.

Case 1 (Without

nailing)

Case 2 (With top

nailing)

Case 3 (With top and

bottom nailing)

0

10

20

30

40

50

60

0

100

200

300

400

500

600

Load(kN)

Horizontal displacement at wall top (mm)

Case1 (Without reinforcement)

Case2 (With top nailing)

Case3 (With top and bottom nailing)

Figure 8. Loading process and load-displacement relationships