2056

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

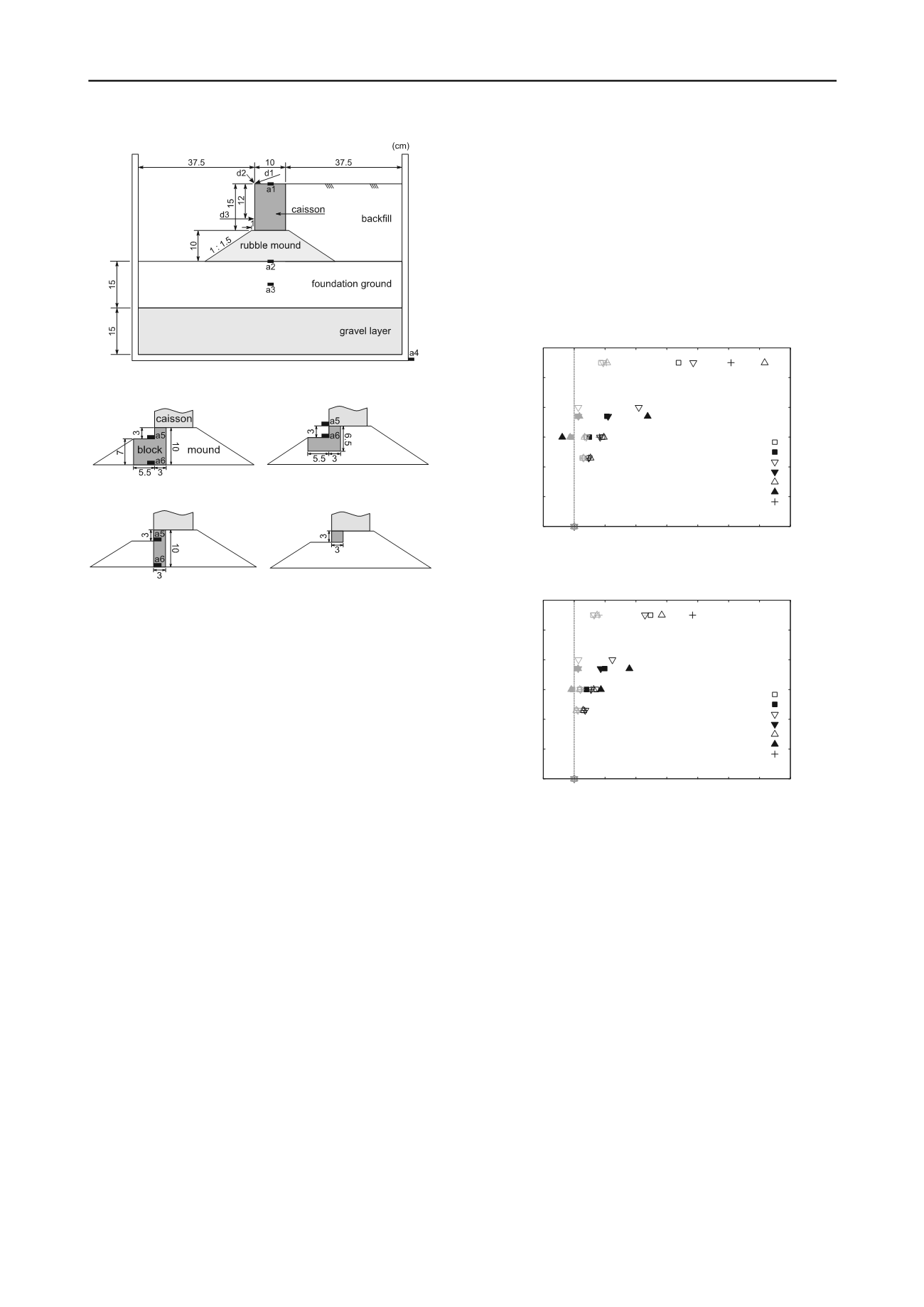

Figure 4. Schematic view of the model ground.

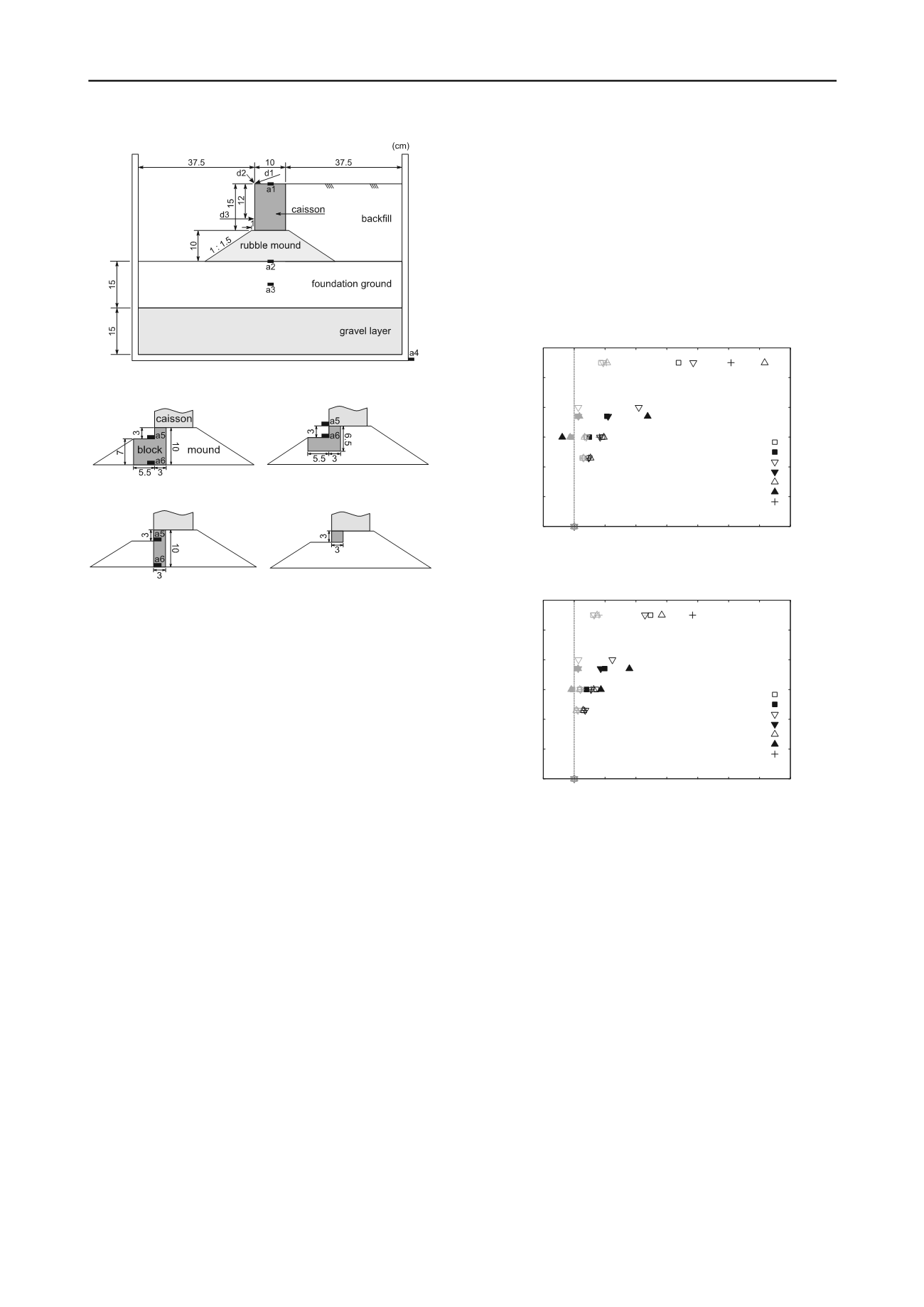

Type 1

Type2

Type 3

Type 4

Figure 5. The blocks used in the tests to simulate solidified area in the

rubble mound.

First, foundation ground was made by the air pluviation

method with Souma sand #6 (

s

= 2.649g/cm

3

,

dmax

=

1.544g/cm

3

,

dmin

= 1.169g/cm

3

,

D

60

= 0.161mm). Relative

density of the foundation ground was about 60%. A rubble

mound was built on the foundation ground by gravel #7 (single-

sized crushed stone S-5, JIS A 5001) whose particle size was

from 2.5 to 5mm. The gravel was placed into a mound by hand,

and was not compacted. Density of the rubble mound was about

1.5g/cm

3

. The solidified area in the mound was modeled as a

block made of cement paste, and put in the rubble mound. The

surface of the rubble mound was covered by gauze to prevent

sand particles from dropping into voids within the rubble

mound. Then a caisson was located on the mound. The caisson

was a wood box in which sand was filled to adjust its weight.

Density of the caisson was 0.98g/cm

3

. Finally, backfill was

prepared in the same way as the foundation ground.

In the series of tests, blocks having the four shapes, shown in

Figure 5, were used. Moreover, the model of the quay wall

before improvement, a model without any blocks as shown in

Figure 4, was tested.

Accelerometers were placed at points a1-a6 shown in

Figures 4 and 5. Acceleration of the shaking table was measured

at a4 in Figure 4. Displacement of the caisson was measured at

d1-d3. The caisson was divided into three parts in the direction

of the face line of the quay wall. The face line is perpendicular

to the plane of this page in Figure 4. The measurement was

conducted at the center of the caisson to eliminate the effect of

friction between the caisson and side walls of the sand box. The

blocks, which were the models of solidified area, were divided

into three parts in the same manner.

The input wave was a sine wave with a frequency of 10Hz

and a wavenumber of 50. Direction of the shaking was

perpendicular to the face line of the quay wall. The model was

tested by the input wave with 100Gal maximum acceleration,

and the residual deformation of the model was recorded by

digital camera. Next, the amplitude of the input wave was

increased to 200Gal maximum acceleration, and the model was

tested again. In this manner, the model was tested with the input

waves whose maximum acceleration was 100, 200, 300, 500,

and 800Gal. Several tests were aborted at 500Gal, because

deformation of the models was too large to continue the test

procedure.

The objective of the tests was to evaluate the variation of

vibrational properties and deformation mode caused by the

different shapes of the solidified area. The similarity rule for the

model was not considered. The tendency of the vibration and

deformation of the models was compared relatively, and

derivation of the factor which affected the behavior of the quay

wall from the comparison was attempted.

0

10

20

30

40

50

60

0.8 1.0 1.2 1.4 1.6 1.8 2.0 2.2 2.4

elevation (cm)

amplification

gray: 100Gal black: 300Gal

Type1 (a1-a4)

(a5,a6)

Type2 (a1-a5)

(a6)

Type3 (a1-a4)

(a5,a6)

without block (a1-a4)

Figure 6. Amplification of acceleration seaward.

0

10

20

30

40

50

60

0.8 1.0 1.2 1.4 1.6 1.8 2.0 2.2 2.4

elevation (cm)

amplification

gray: 100Gal black: 300Gal

Type1 (a1-a4)

(a5,a6)

Type2 (a1-a5)

(a6)

Type3 (a1-a4)

(a5,a6)

without block (a1-a4)

Figure 7. Amplification of acceleration landward.

3. VIBRATIONAL PROPERTY OF QUAY WALL

The vibrational property of the quay wall would be different

before and after the improvement. Figures 6 and 7 compare the

maximum acceleration amplitude between the models with

differently shaped blocks. Figures 6 and 7 also show the

amplitude observed in the test of the model without any blocks.

Gray marks in the figures show the results observed with the

input waves whose maximum acceleration was 100Gal, while

black marks show the results with 300Gal. The maximum

acceleration amplitudes in figures were calculated as follows:

find the maximum acceleration in each cycle of sine waves,

calculate the average of the maximum acceleration for the

whole of input waves (50 cycles), and divide the average value

by the average of the maximum acceleration of a4 (the

acceleration of the shaking table, elevation = 0cm). The

acceleration time histories were stable for all tests with 100 and

300Gal acceleration, and the maximum acceleration for each

cycle remained largely unaltered during the shaking. The

calculation was made for each direction; Figure 6 shows the

amplitude of acceleration seaward (from the right-hand side to

the left in Figure 4) and Figure 7 shows that landward (from left

to right in Figure 4). In the case of the tests in which the

maximum acceleration of the input wave was larger than

500Gal, large deformation was induced and the accelerometers