2053

Technical Committee 207 /

Comité technique 207

0

5

10

15

0

100 200 300 400 500

Depth (m)

Bending distortion (micro)

Vertical, excavation of 3.3 m depth

Vertical, excavation of 9.6 m depth

10deg.inclination, excavation of 3.3 m depth

10deg.inclination, excavation of 9.6 m depth

Active pressure

distribution

Passive pressure

distribution

Plastic zone

GL

GL

-5.27

Elastic zone

Sliding surface with

minimum safety factor

Retaining wall

0

5

10

15

0

50

100

150

Depth (m)

Earth pressure

Beforeexcavation

Excavation of 3.3 m depth

Excavation of 5.3 m depth

Excavation of 9.6 m depth

Earth pressure at rest (0.5)

Coulom'searth pressure

(kN/m

2

)

0

5

10

15

0

50

100

150

Depth (m)

Earth pressure

Beforeexcavation

Excavation of 3.3 m depth

Excavation of 5.3 m depth

Excavation of 9.6 m depth

Coulom'searth pressure

Earth pressure at rest (0.5)

(kN/m

2

)

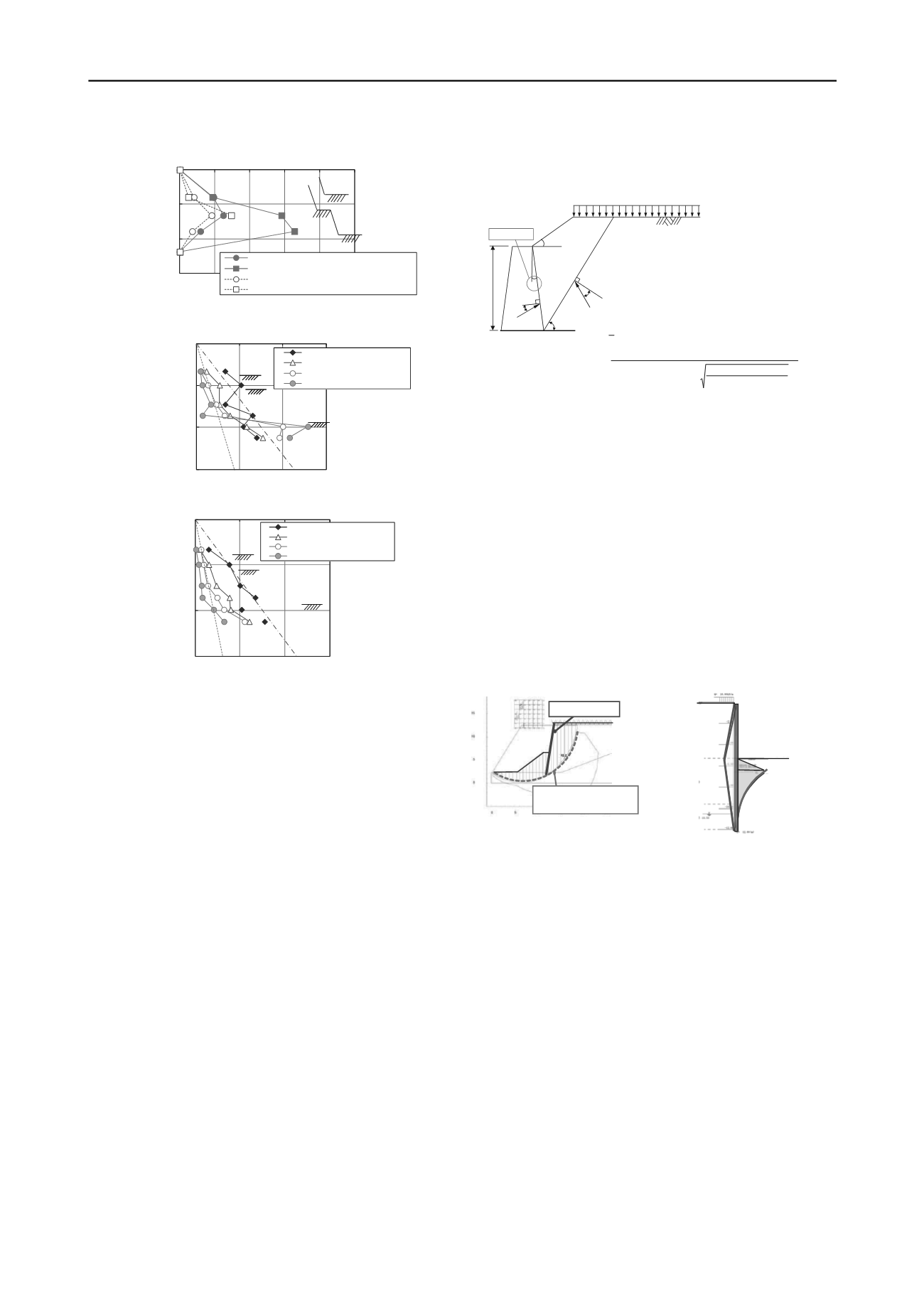

Figure 7. Bending strain distribution of retaining

Figure 8. Earth pressure acting on wall surfaces - vertical retaining walls

Figure 9. Earth pressure acting on wall surfaces - inclined retaining walls

Figures 8 and 9 show the depth distribution of the active

earth pressure that acted on the wall. Although the measurement

results for the vertically installed wall showed dispersions prior

to excavation, the validity of the earth pressure measurements

taken by this equipment were confirmed because they were

approximately equal to the earth pressure at rest assuming Ko =

0.5, as noted in the figure. The earth pressure decreased in the

excavated sections and increased more than the earth pressure at

rest in the embedded sections. The figure shows the Coulomb’s

earth pressure, where the friction angle of the retaining wall was

considered to be φ/3. The active earth pressure measured at the

excavated sections was slightly smaller in distribution than the

Coulomb’s earth pressure. The earth pressure acting on the

inclined wall decreased more than the earth pressure at rest

regardless of depth. Thus, the acting pressure was smaller than

that of the vertically installed wall, which confirmed that

inclination of the wall contributed to the stability of the wall in

terms of earth pressure as well.

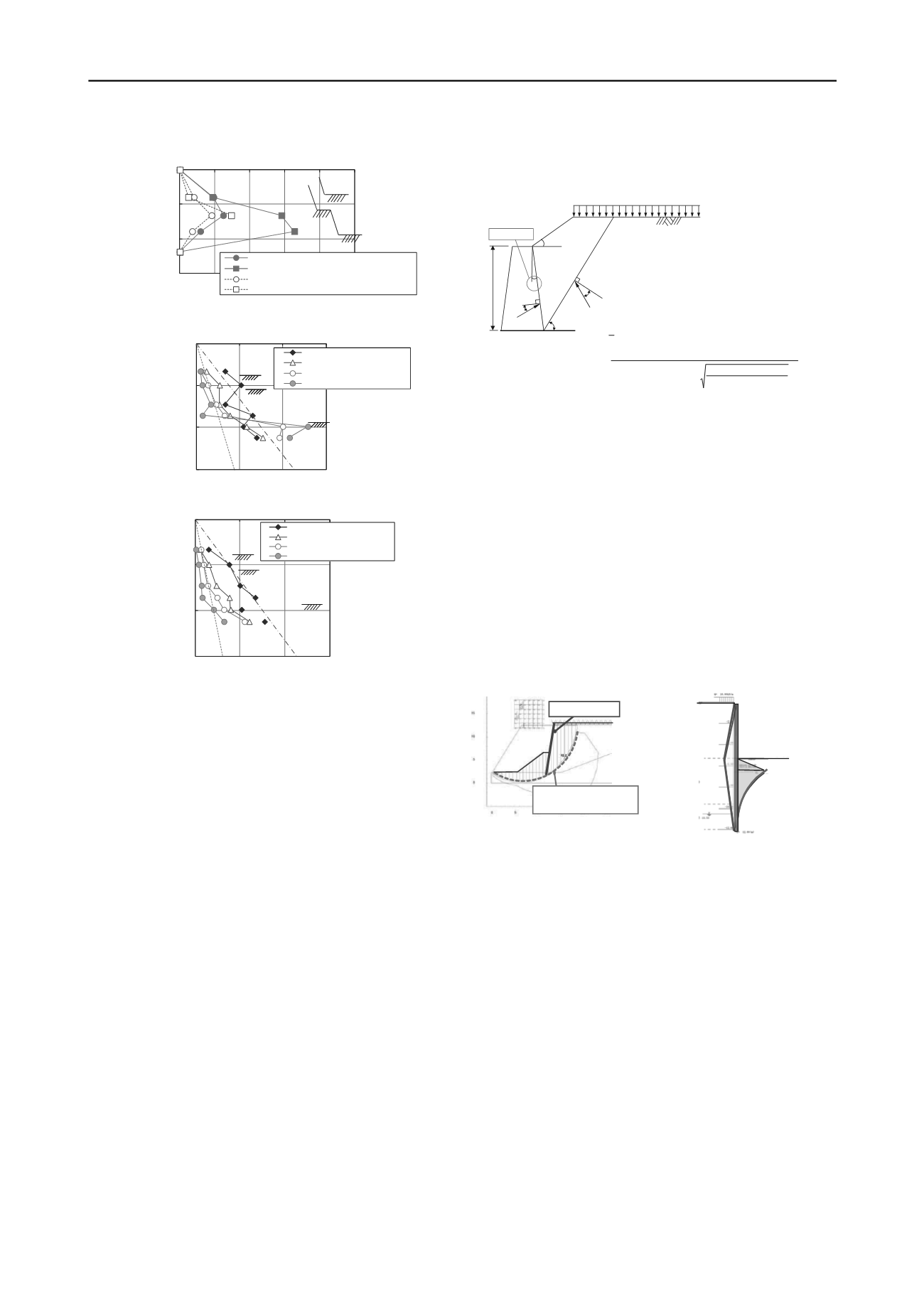

4 DESIGN OF INCLINED-BRACELESS RETAINING WALL

4.1

Calculation method for earth pressure

Ground of the site (Figure 3) was a landfill comprised primarily

of loose fine sand (layer thickness: 12 m, N-value: 3–5, and φ:

33°). The inclination of the retaining wall could not be

considered in the conventional design of the temporary

retaining walls, because the Rankine–Resal formula is generally

applied to the active earth pressure used. The earth pressure

calculation method with Coulomb’s formula (Figure 10) used in

the design of permanent retaining walls, which considers the

inclination of the wall, was therefore applied. Its use was

determined safe for design purposes because the earth pressure

reduction effect was confirmed in the centrifugal model

experiments with inclined walls. Similarly, the Coulomb’s earth

pressure was adopted for the passive earth pressure.

H

α

β

δ

P

A

ω

φ

R

3

Figure 10. Active earth pressure calculation

4.2

Calculation method for embedding lengths

The embedding length was calculated using not only the

“method for determining embedding length to maintain balance

based on earth pressure” but also the “overall slippage including

the retaining wall.” The circular slipping calculation (Figure 11)

was performed to determine the embedding length so that both

of the above methods were satisfied. The safety factor for the

arc slipping calculation was set to 1.2.

4.3

Calculation of retaining wall displacements and stresses

The displacements and stresses that occurred with the retaining

wall were calculated based on elasto-plasticity analysis, which

evaluated the earth pressure and wall embedding length given in

subsections 4.1 and 4.2 above, by considering the retaining wall

as a finite length elastic beam and ground as an elasto-plastic

spring (figure 12).

5 CONSTRUCTION WORK IMPLEMENTATION RECORD

FOR INCLINED-BRACELESS RETAINING WALLS

5.1

Summary of applied construction sites

The construction sites where the inclined-braceless retaining

walls were applied were located within premises used by

existing electric power plant and new plant construction.

Excavation work had to be performed to install two sets of

water intake and water discharge steel pipes (each pipe with a

diameter of 2800 mm) in a restricted construction work zone

with a width of 30 m (Figures 3 and 13). The period of

construction work, which included piping work, needed to be

less than six months owing to adjustments that had to be made

to accommodate the progress of the main unit construction work

being performed at new electric power plant.

In order to satisfy the above conditions, the inclined-

braceless excavation retaining wall construction method which

reduces earth pressure by inclining the wall, was adopted as it

requires no shoring, even when the excavation depth is deep.

The retaining wall was fabricated from steel sheet pile type SP-

IV, and the inclination of the retaining wall was set to 10 degree

owing to restrictions imposed within the construction work zone

and the excavation cross section necessary for piping work.

Figure 11. Verification on

slipping stability

Figure 12. Elasto-plastic analysis

α

=

-10deg.

2

2

2

2

cos

cos

sin

sin 1

cos

cos

cos

2

1

A

A

A

K

H K P

P

A:

Active earth pressure of Coulomb

K

A

: Active earth pressure coefficient of slope

α: Angle created by wall back surface and vertical plane

β: Slope angle of back ground

δ: Friction angle of wall surface

φ: Angle of shearing resistance of sand

H: Height of wall on which earth pressure acts

γ: Unit weight of soil