2061

Technical Committee 207 /

Comité technique 207

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

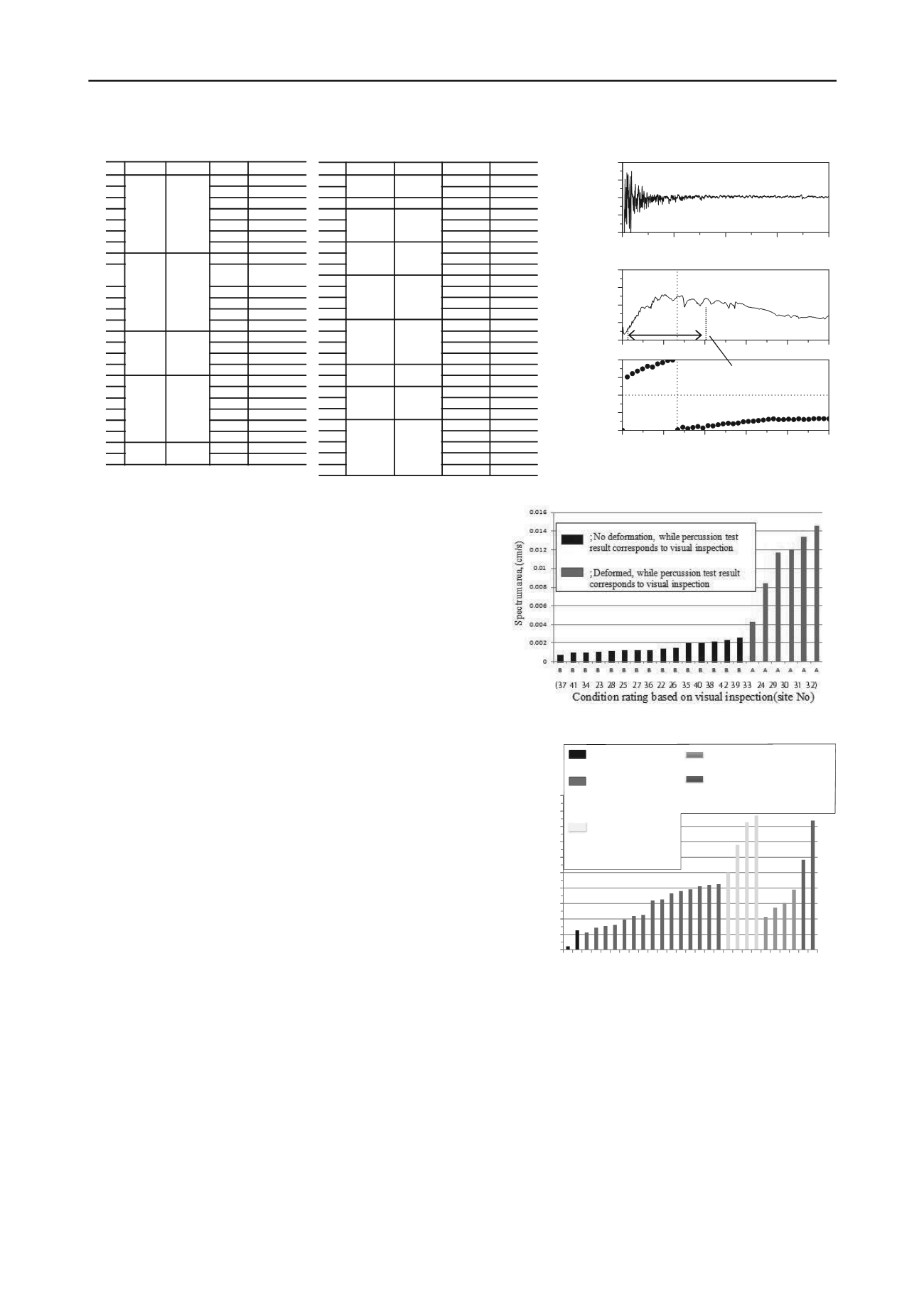

spectrum area. In the cases of ashlars wall shown in Figure 5,

the values of spectrum area Sa of retainig walls rated as

“

A(deformed)

”

were genellary larger than the ones of retainig

walls rated as

“

B(no deformation)

”

, which shows the validity of

spectrum area for the condition rating of retaining walls.

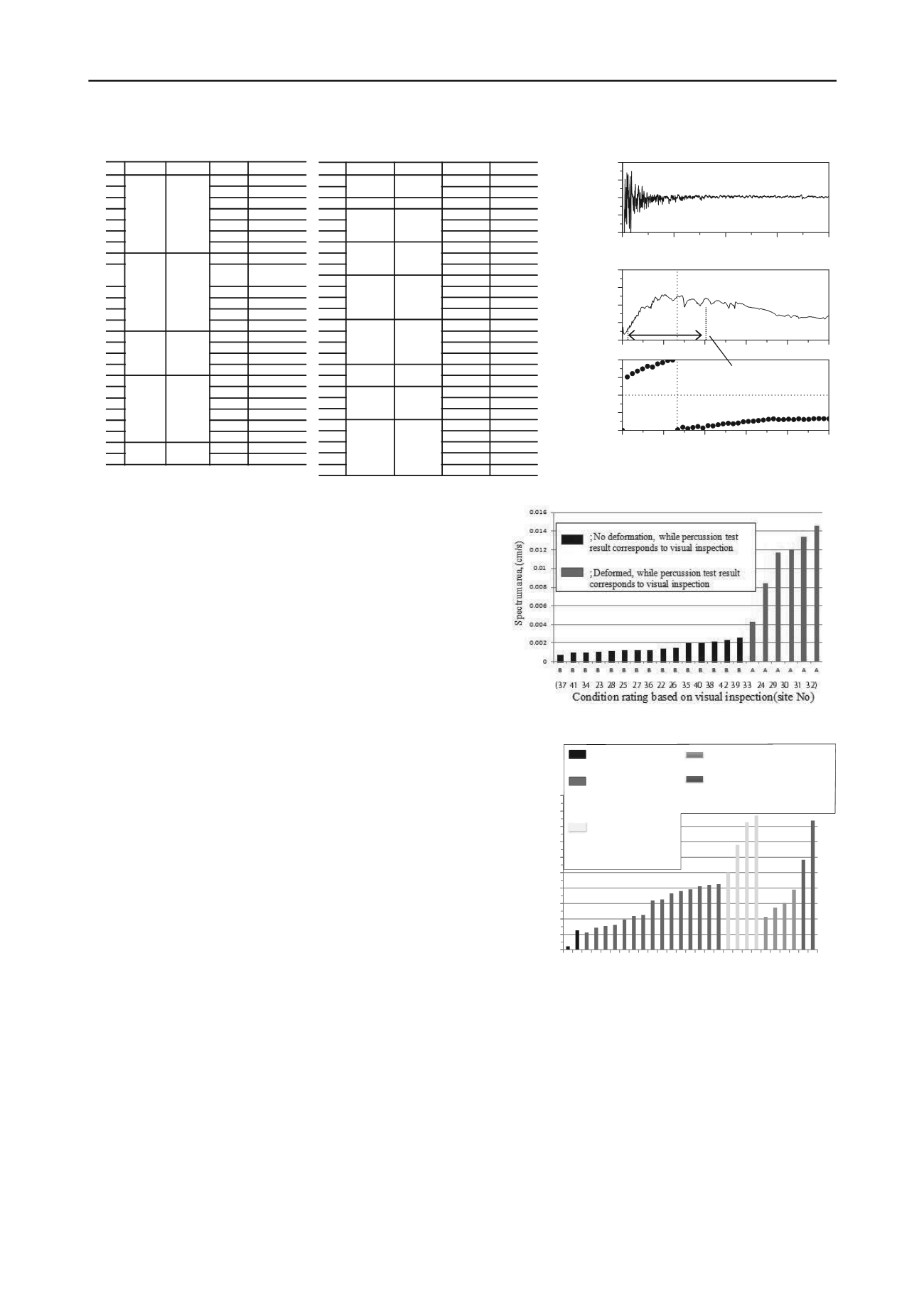

In the cases of the leaning type retainig wall shown in

Figure 6, a good corelation between the result of visually

inspected condition rating and the values of spectrum area could

not be found. In the sites No. 6, 20, 21 and 24, the values of

spectrum area was much larger than the other sites although

they were rated as

“

B (no deformation)

”

, which might imply

that the progress of the deformation at the part in which is

difficult to detect by visual inspection (e.g. subsoi, backfill, etc.).

On the other hand, at the sites 27, 26, 25 and 3, the values of

spectrum area were not necessarily larger than the other sites

although they were categorized as

“

A(deformed)

”

.

Percussion test has some problems (Nakajima et al., 2012) ;

1) heavy weight of iron ball (safety, portability) , 2) scattering

of impact force depending on inspectors (repeatability) and 3)

attenuation of inpact force especially in high frequency

range(limited range of input frequency). In applying to the

condition rating of retaining wall, second and third problems

would make it difficult to rate the condition of the retaining wall

properly especially in the case of the leaning type retaining wall.

Therefore, the authors developed a small scale exciter (Shinoda

et al., 2012), which could apply constant sweep sinusoidal

excitation under mechanically manupulation, which could solve

second and third problems. A prototype scale loading test on

leanining type retaining wall model was conducted so as to

examine the applicability of the newly developed small scale

exciter.

4 PROTOTYPE SCALE LOADING TEST

Cross section of constructed leaning type retaining wall with

height of 4.3 m and width of 1.5 m is shown in Figure 7. In

Figure 7, the outline of the develope small scale exciter is also

summarized. Retaining wall was constructed on the stiff base

layer while its backfill consisted of the cobbles, sand backfill

with degree of compaction

D

c

of 90 % and densely compacted

gravelly sand. In the loading test, the retaining wall was

subjected to the cyclic loading and unloading processes by

applying the vertical load at the surface of the backfill using the

hydraoulic jack while their amplitude were gradually increased

as shown in Figure 8. Gravelly sand layer inclined 30 degrees

from the horizontal direction so as to apply horizontal load to

the retaining wall efficently.

In the loading test, cyclic loading and unloading proccesses

were applied to the leaning type retaining wall model (Case 1).

A soil nailing reinforcement with diameter of 60 mm and length

of 4000 mm was installed after horizontal displacement at the

wall top exceeded 50 mm. As the second case (Case 2), the

model wall reinforced with the top nailing was subjected same

loading and unloading processes with Case 1. Lastly, the model

wall with top and bottom nailing, which was installed after Case

2, was subjected to the same loading processes while the

maximum amplitude of load was applied to the wall in the end

Table 2 Summary of test sites in this study

No. Company Type Height(m) Deformation

1

A Leaning

7.2

None

2

7.2

None

3

7.2

Cracking

4

7.2

None

5

7.2

None

6

7.2

None

7

7.2

None

8

B Leaning

6.3

Cracking

9

6.3

Cracking

Horizontal disp.

10

6.3

Cracking

11

6.3

None

12

3.9

Cracking

13

3.35

None

14

C Leaning

3.6

None

15

3.6

None

16

3.6

None

17

3.6

None

18

D Gravity

4..8

None

19

4.3

None

20

3.3

None

21

3.7

Cracking

22

2.9

Cracking

23

3.2

None

24

E Leaning

4.15

None

25

4.15

None

No.

Company Type

Height(m) Deformation

26

F

Leaning

3

None

27

2.64

None

28

G Leaning

3.95

None

29

H Leaning

5.48

Cracking

30

5.48

Cracking

31

5.48

Cracking

32

I

Ashlars wall

5.4

Cracking

33

6.4

None

34

2.4

Cracking

35

J

Ashlars wall

4.2

None

36

4.1

None

37

4.1

None

38

4.1

None

39

K Ashlars wall

4

Inclination

40

4

Inclination

41

4

Inclination

42

4

Inclination

43

L Ashlars wall

5.7

Cracking

44

5.4

None

45

M Ashlars wall

2.6

None

46

3

None

47

3.4

None

48

N Ashlars wall

3.3

None

49

3.3

None

50

3.3

None

51

3.3

None

52

3.3

None

0

20

40

60

80 100

0.0

1.0x10

-3

2.0x10

-3

3.0x10

-3

4.0x10

-3

上部(ch1)

26.6Hz

振幅

(

cm /s*s

)

振動数(H z)

0

20

40

60

80 100

0

90

180

270

360

上部(ch1)

位相(度)

振動数(H z)

26.6Hz

a)

Frequency (Hz)

Time(sec)

b)

c)

Phase (deg.)

Amplitude (cm/s*s)

0

1

2

3

4

-2.0x10

-2

-1.0x10

-2

0.0

1.0x10

-2

2.0x10

-2

上部(ch1)

時間(s)

速度(cm /s)

Velocity (cm/s)

*3 to 40 Hz are selected

for spectrum area

evaluation

Figure 4. Example of test result obtained from site No.3

Figure 5. Relationships between condition rating by visual inspection

and value of spectrum area (Ashlars wall)

Condition rating based on visual inspection

(

Site No.

)

Spectrum area, Sa

(

cm/s

)

(9 12 14 16 19 18 15 13 17 7 11 5 1 2 22 23 4 6 20 21 24 27 26 25 3 10 8 )

0.0000

0.0005

0.0010

0.0015

0.0020

0.0025

0.0030

0.0035

0.0040

0.0045

0.0050

S S B B B B B B B B B B B B B B B B B B B A A A A A A

; No deformation (with

reinforcement)

; No deformation,

while percussion test

result corresponds to

visual inspection

; Possibly deformed,

while difficult to

detect by visual

inspection

; Deformed, while percussion test

result corresponds to visual

inspection

; Further investigation is

required

Figure 6. Relationships between condition rating by visual inspection

and value of spectrum area (Leaning type retaining wall)