2048

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

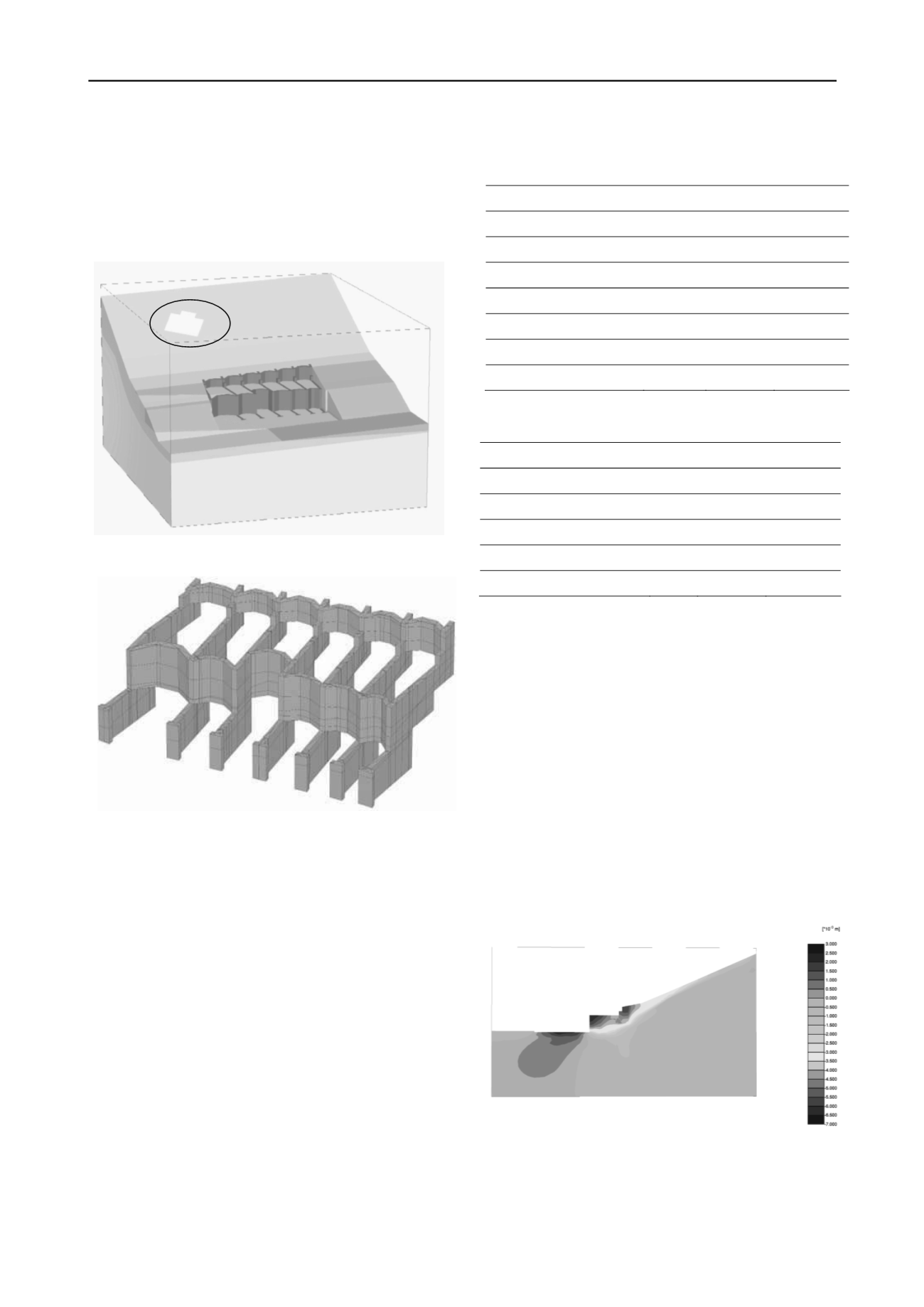

constructed by mixed in place columns (MIP), which rest on

supporting walls (also mixed in place columns) oriented in the

direction of the slope. The earth pressure exerted from the slope

was transferred to 5 meter deep mixed in place walls underneath

the planed building at the base of the slope. Figure 1 shows the

slope with the supporting structure and Figure 2 a detail of the

MIP columns.

Figure 1. Overview of slope and support structure including critical

building.

Figure 2. Layout of support structure (MIP columns).

Based on the results from site investigations a representative

underground model consisting of three layers was established

for the 3D finite element analysis, namely soft sandy silt (0-4 m

below surface), stiff laminated sand-silt (4-8 m below surface)

and semi-solid sand-silt (below 8 m from surface). The most

important parameters for these layers are summarized in Table

1. E

oed

ref

is the stiffness from an oedometer test for the reference

vertical effective stress of 100 kPa, E

50

ref

is a secant stiffness at

50% of maximum deviatoric stress in a triaxial compression test

at a reference cell pressure

3

' = 100 kPa, E

ur

ref

is the

unloading/reloading stiffness, again at a reference cell pressure

of 100 kPa from a triaxial test, and m is a parameter

determining the stress dependency of above stiffness

parameters.

', c' and

are the conventional Mohr-Coulomb

strength parameters which define ultimate strength in the

Hardening Soil model.

The MIP-method improves the mechanical properties of a

soil by mechanically mixing and adding binder slurry. The

result is a “soil-concrete-mixture” in which the soil is used as

aggregate. For the MIP-columns a constitutive model based on

the Mohr-Coulomb failure criterion was applied. Based on an

unconfined compressive strength of 5 MN/m², whereas this

value includes a partial factor of safety on material strength, the

material parameters listed in Table 2 have been adopted.

Table 1. Material parameters for Hardening Soil model for soil layers.

Table 2. Material parameters for MIP-columns.

Parameter

MIP

Friction angle,

' (°)

30

Cohesion, c' (kPa)

250

Unit weight,

(kN/m

3

)

22

Elasticity modulus (kPa)

300000

Tension cut off,*

t

(kPa)

125

* based on reinforcement by steel rods and nails

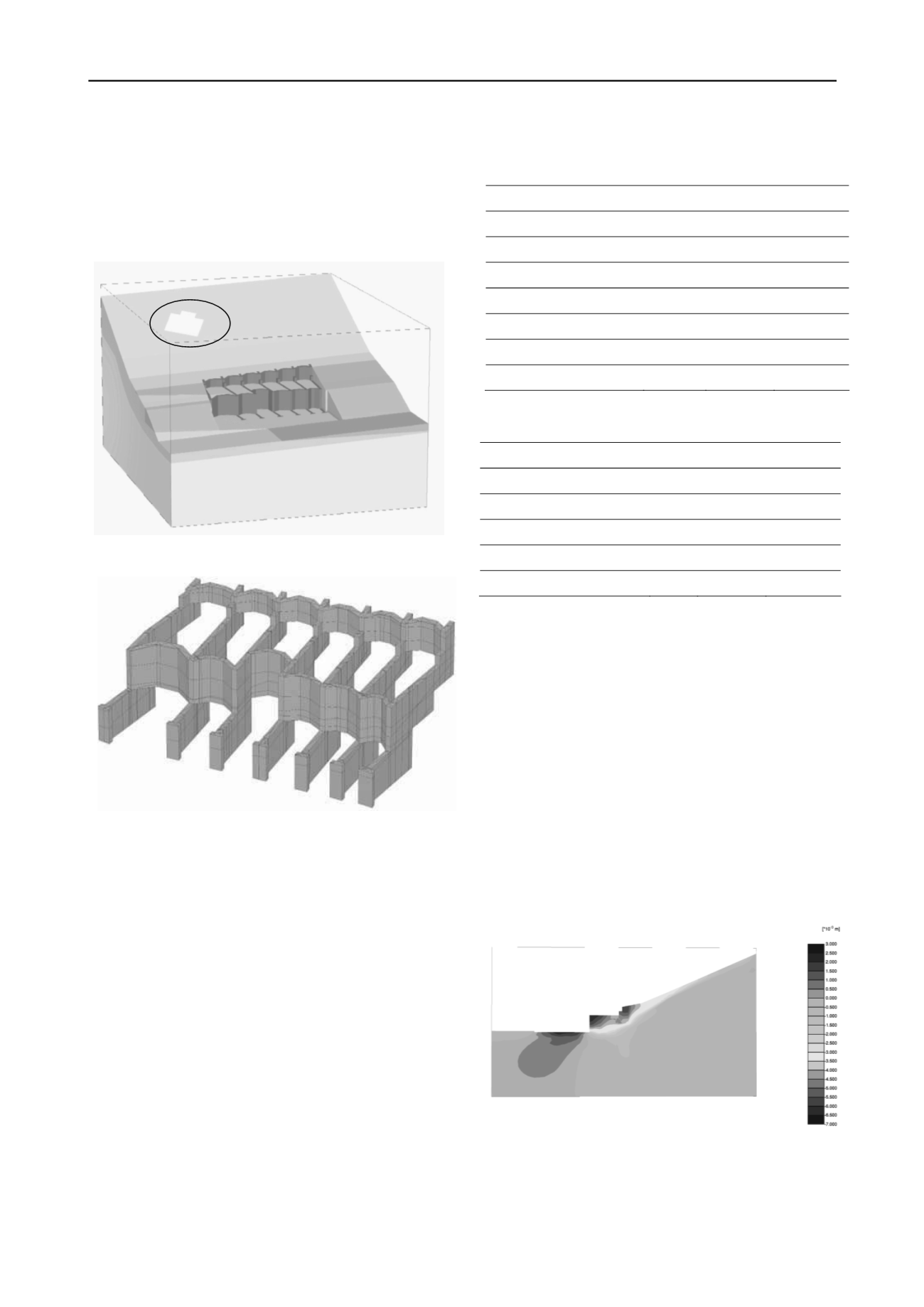

The results of the calculation show the expected stiff behaviour

of the chosen support system. The maximum calculated

horizontal deformation of about 15 mm occurs at the front upper

corner of the lower excavation step (Figure 3). At the back of

the wall (near the border of the neighbouring property)

deformations are in the order of millimetres and thus the

expected settlements in this area can be considered to be not

significant and will not cause any damage to the building

(Figure 4). However, the finite element analysis could not

model the construction process of the MIP-columns, i.e. the

columns were assumed "wished-in-place" before excavation

starts and therefore displacements due to the construction

process have to be added to these values.

The 3D-model was also used to check the tension zones in

the MIP-body. The main tension stresses were located at the

connections of the arches and the wall elements. In this area the

MIP-wall was reinforced with steel beams (HE-B profiles).

Figure 3. Calculated horizontal displacements, cross section

The measurements during construction on one hand confirmed

the results for the numerical analysis but on the other hand

showed that significant deformations occurred during

construction of the MIP-columns itself (Figure 5). After

construction of the columns (panels) deformation measured

were less than 15 mm, comparing well with the finite element

Parameter

Layer 1

Layer 2

Layer 3

Friction angle,

' (°)

25

27.5

30

Cohesion, c' (kPa)

0

1

5

Dilatancy angle,

(°)

0

0

0

Unit weight,

(kN/m

3

)

20

20.5

21

E

oed

ref

= E

50

ref

(kPa)

10000

25000

45000

E

ur

ref

(kPa)

30000

75000

135000

m (-)

0.5

0.5

0.5