2049

Technical Committee 207 /

Comité technique 207

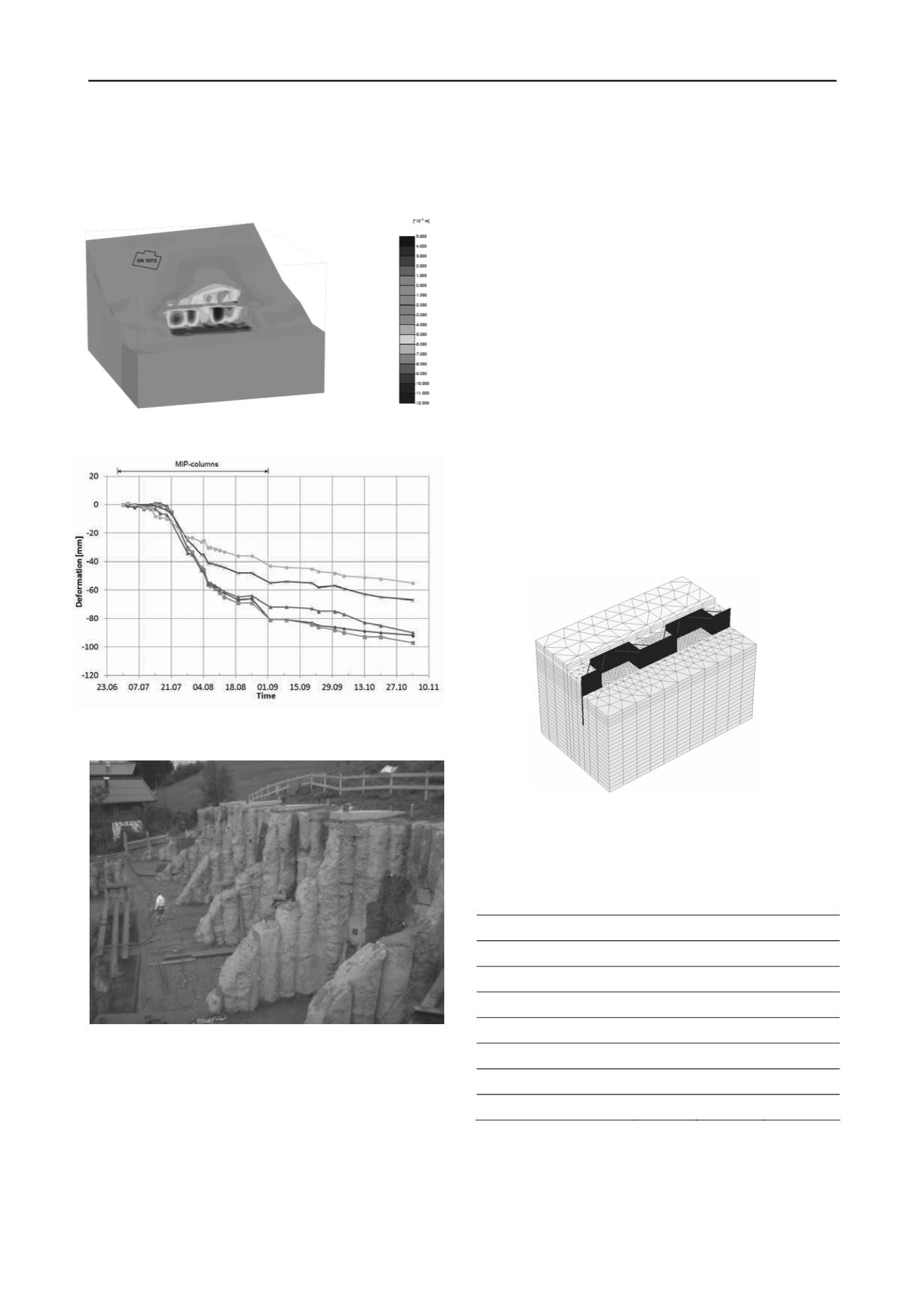

predictions. Figure 5 shows the deformations of different points

on the top of the MIP-wall. At the neighbouring buildings no

movements were recorded. Figure 6 presents a view of

excavated MIP-walls.

Figure 4. Calculated horizontal displacements with critical building

Figure 5. Measured horizontal displacements at several points at the top

of the MIP-wall

Figure 6. View of excavated MIP-walls

The large deformations during the production of the columns

had two main reasons. In the first part of the production too

many MIP columns were produced within a small area. The

MIP columns, which take some time to gain strength, weakened

the slope during construction, which was already close to

critical state. Furthermore, to reduce the length of the MIP

columns (in order to save money), deeper working planes than

planned were excavated.

This presented case study clearly shows that it is possible to

support the earth pressure exerted from a slope by arches

constructed by means of soil improvement techniques without

any anchors reaching on neighbouring ground. The numerical

analysis was able to prove that the design concept is feasible,

however, it is important to observe the deformation during the

construction stages because not all aspects of the construction

process, in this case of the MIP-columns, can be taken into

account in the numerical model.

4 EXAMPLE 2 - SERRATED SHEET PILE WALL

The second example is concerned with the same problem,

namely limited space for support measures, but this time it is in

an urban environment, namely in the city of Salzburg, Austria.

Again the excavation was very close to the adjacent property

and it was not allowed to put any construction elements, such as

ground anchors, there. In this case the solution chosen was a

serrated sheet pile wall. Generally, the subsoil conditions in

Salzburg consist of a top layer with backfill and gravel, and soft

silty sand and clayey silt layers underneath. The layout of the

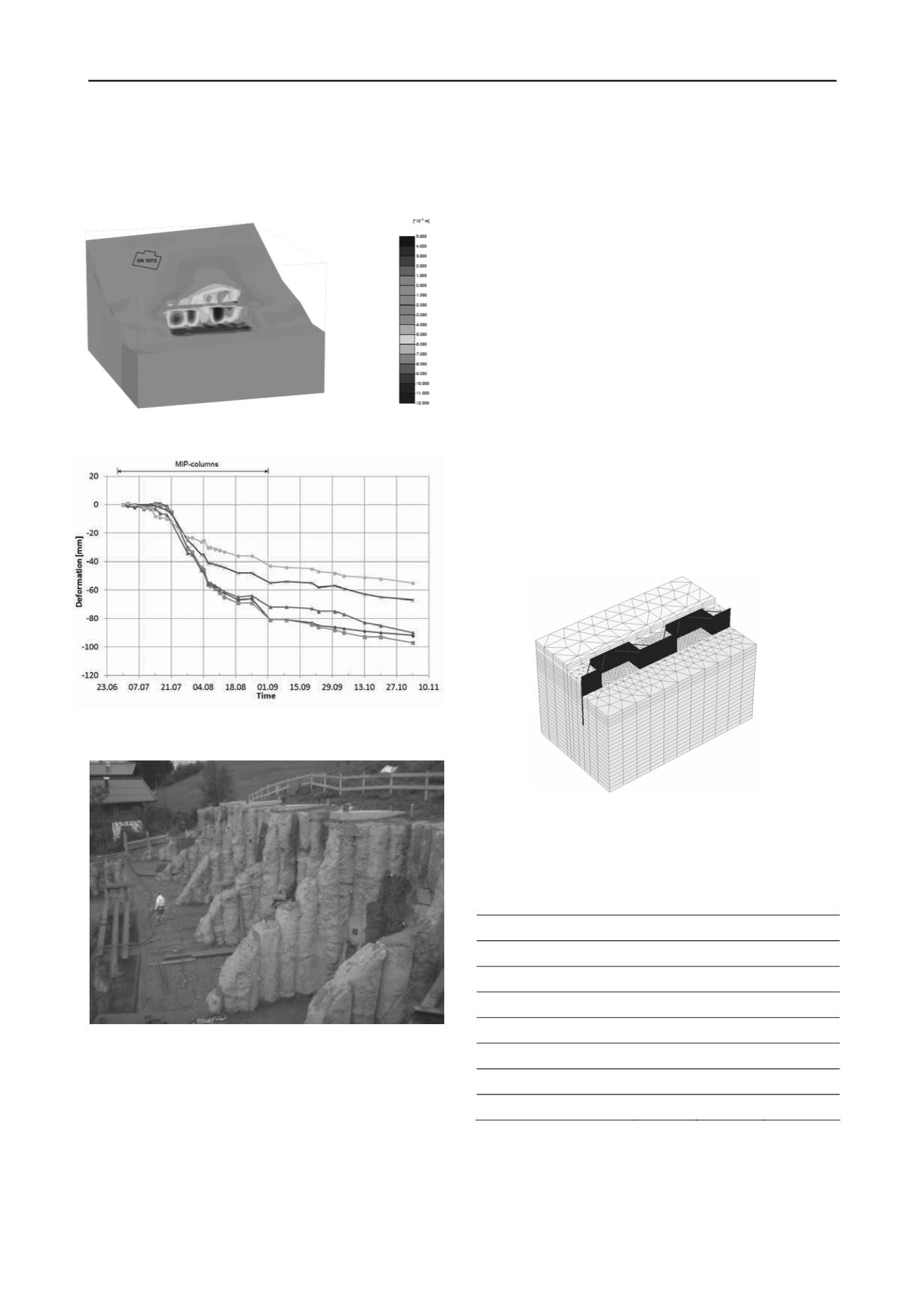

sheet pile wall follows from Figure 7 (3D finite element model).

Every 6 to 8 m there is a 3 m deep indentation in the sheet pile

wall. The construction of diagonal compression and tension bars

at the top transfers the earth pressure to the right-angled parts of

the sheet pile walls. A steel construction, similar to a whaler

beam, on top prevents non-homogeneous deformations of the

wall. After excavation a drainage layer and a concrete slab is

installed to prevent long term movements of the wall and to

reduce the influence of the soft layers below excavation level.

Figure 7. 3D finite element model

The key material parameters for the soil layers considered in the

analysis are listed in Table 3. Again the Hardening Soil model

has been employed.

Table 3. Material parameters for Hardening Soil model for soil layers.

Parameter

backfill

silty sand

clayey silt

Friction angle,

' (°)

35

27.5

25

Cohesion, c' (kPa)

0,1

3

5

Dilatancy angle,

(°)

0

0

0

Unit weight, (kN/m

3

)

19/21

20/21

18/20

E

oed

ref

= E

50

ref

(kPa)

52000

30000

15000

E

ur

ref

(kPa)

208000

120000

60000

m (-)

0

0.5

0.5

The 3D model showed that deformations can be kept to a

minimum with maximum values below 10 mm (Figure 8),

which was also confirmed by observations during construction.

Deformations due to driving and removing of the sheet pile wall

are not considered in the analysis. Experience has shown that in

this type of soils settlements can reach 20 to 30 mm, and in this

particular case observed values were within the lower range.