2072

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

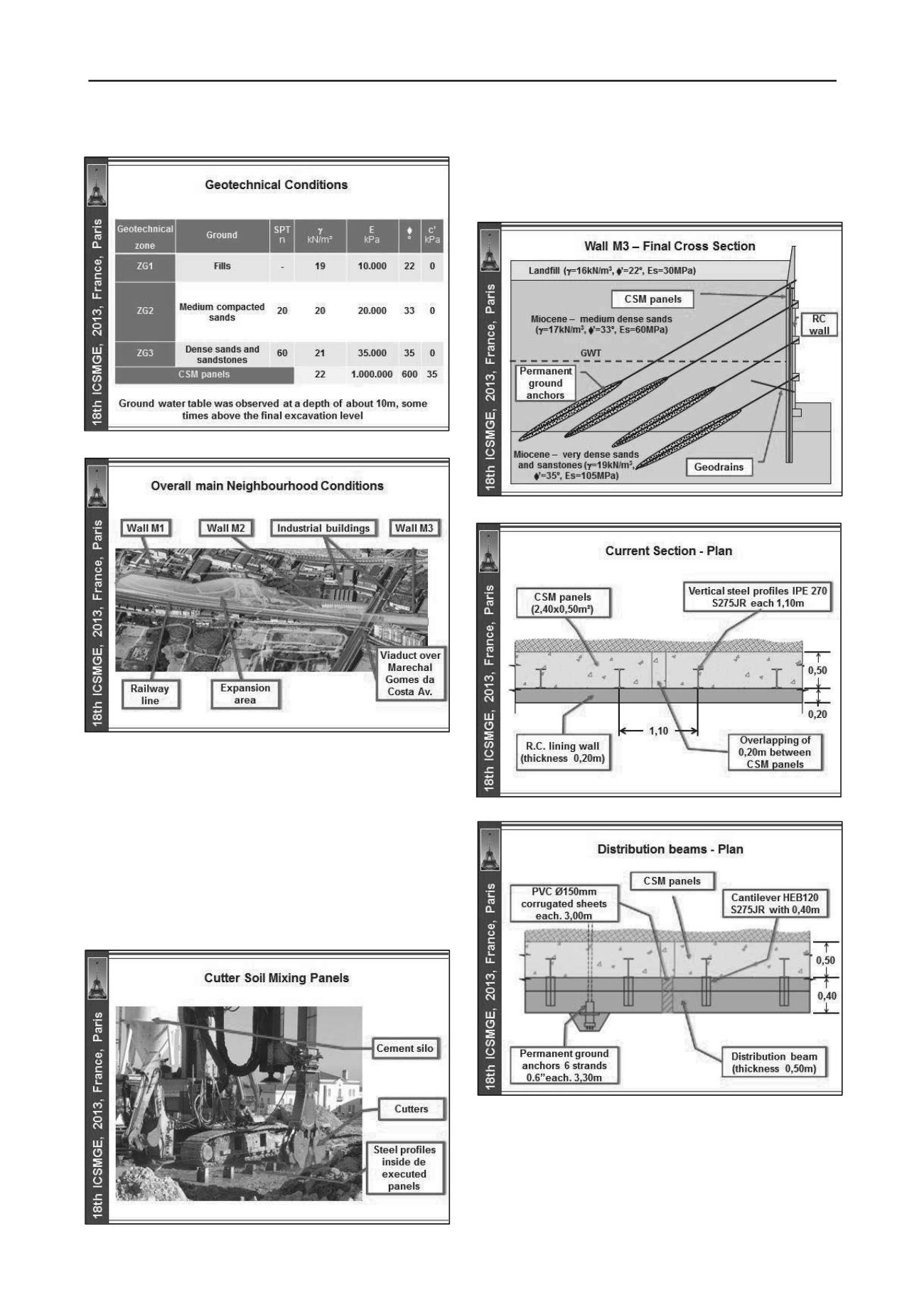

Figure 3. Main geotechnical conditions.

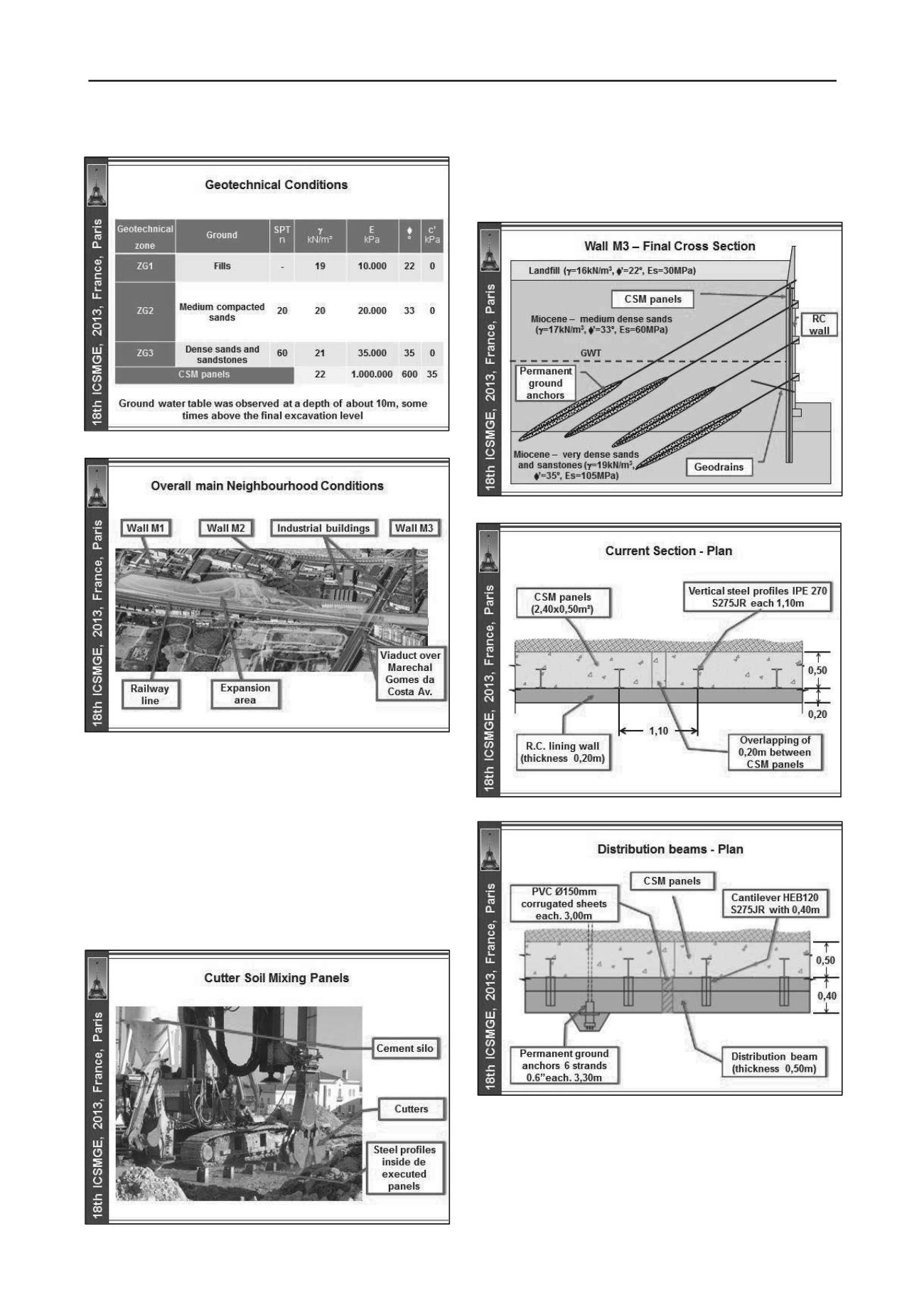

Figure 4. Overall main neighbourhood conditions.

3 ADOPTED SOLUTION

In order to allow the excavation works minimizing the ground

loss of confinement effect, soil - cement panels with a

maximum depth of about 18m and a cross section of 2,4 x

0,5m

2

, including 0,20m of overlapping, were preliminarly built

using the CSM technology. The panels were reinforced with

vertical IPE240 hot rolled steel profiles (Euronorm 19-57),

spaced in average 1,1m, in order to resist to the earth and

ground water pressures, as well as to assure a better control of

the retaining structure deformations (Figure 5).

Figure 5. Execution of the soil - cement panels using CSM technology.

The steel profiles were placed inside the soil - cement

panels, before the cement started the curing process, and were

braced by four or three levels of permanent ground anchors,

applied at the reinforced concrete capping beam, as well as at

the distribution beams (Figures 6, 7 and 8).

Figure 6. Final cross section of the wall M3.

Figure 7. Plan of the wall M3 current section.

Figure 8. Plan of the wall M3 at the distribution beams section.

As already stated, according to the innovative solution

combining the Berlin wall with the CSM technology, the soil -

cement panels were designed in order to be integrated on the

final earth retaining solution, including the 0,2m thickness

lining reinforced concrete (RC) wall and beams (capping and

distribution), and also to minimize the water inflow to the