2078

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

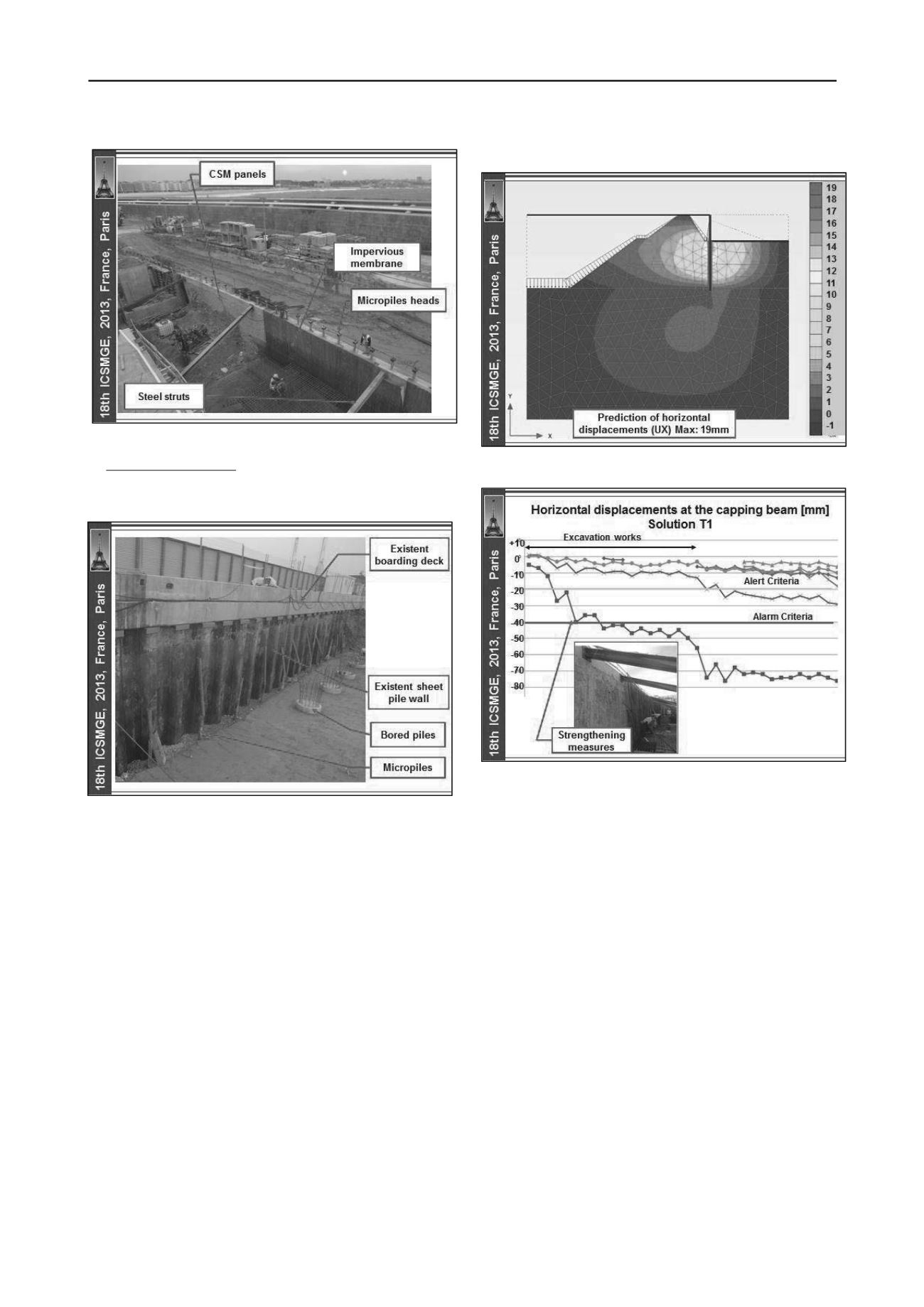

Figure 15. Solution T2 – soil - cement panels after excavation.

Solution type 3 (T3): the existent sheet pile wall was

integrated on the global cofferdam, using a bracing system, steel

ties, connected to the head of the boarding deck foundation piles

(Figure 16).

Figure 16. Solution T3 – view of the sheet pile wall after excavation.

3.2 Foundations

For the foundations of the Terminal building reinforced

concrete bored piles (

800mm and

1200mm) and steel

micropiles N80

139,7x12mm were adopted. Micropiles were

used also to resist to both light compression and tension loads,

when the structure self-weight was not enough to equilibrate the

hydrostatic pressures. Micropiles were designed against

corrosion taking into account a sacrificial thickness. All the

piles and micropiles were capped by a reinforced concrete raft,

cast against an impervious membrane.

4 DESIGN

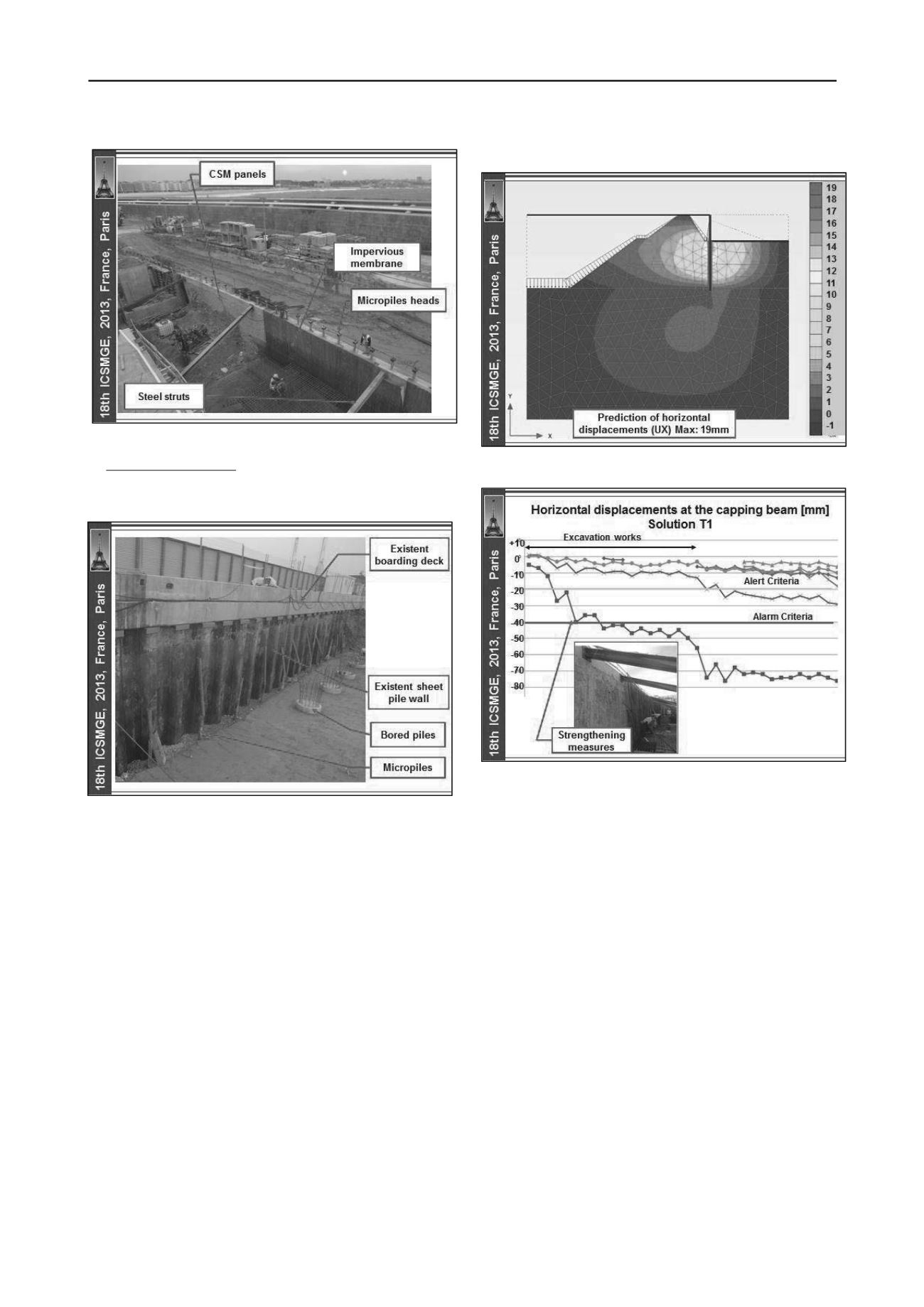

For the design of the adopted solutions, earth retaining

structures and foundations, 2D, including axisymmetric, FEM

analysis was carried out, using Plaxis software (Figure 17).

5 MONITORING AND SURVEY PLAN

A monitoring and survey plan was applied taking into account

the need to perform the construction in safe and economic

conditions, including inclinometers and topographic marks.

Measurements confirmed the excellent overall behavior of the

adopted solution, with the exception of a local area at solution

T1, demanding the implementation of strengthening measures:

inclined steel struts connecting the capping beams to the

foundations piles (Figure 18).

Figure 17. 2D FEM analysis for section T1.

Figure 18. Horizontal displacents at topographic marks - solution T1.

6 MAIN CONCLUSIONS

Taking into account the complex scenario of the presented

work, it is possible to point out the follwing points:

Good water tightness, mainly due to the cofferdam effect

assured by the embedment of the soil - cement panels at

the bed rock, as well as due to the injections cut off

curtain.

Low deformations, confirmed by the monitoring results.

Peripheral r.c. walls with very good finishing faces.

Also very important was the control of both costs and

construction schedule.

7 ACKNOWLEDGEMENTS

The authors are grateful to the owner of the Terminal building,

APDL (Administração do Porto de Leixões), for his permission

to the presentation of this paper. The construction works were

performed by OPWAY and FERREIRAS (general contractors)

and GEORUMO and HAGEN (geotechnical contractors).

8 REFERENCES

Pinto A., Tomásio R., Pita X., Pereira A. and Peixoto A. 2011. Cutter

Soil Mixing Solutions in Portugal on Hard Soils and Weak Rocks.

Proc. 15th European Conference on Soil Mechanics and

Geotechnical Engineering

, September 2011, Athens, Greece, Part 2

– 3.3 – Ground Reinforcement, pp. 1037–1042.